Unburned magnesium-calcium zirconate brick not containing free carbon

A technology of magnesia-calcium-zirconium bricks and free carbon, applied in the field of unfired magnesia-calcium-zirconium bricks, can solve problems such as structural spalling and poor thermal shock resistance, and achieve improved service life, high hydration resistance, and excellent slag erosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

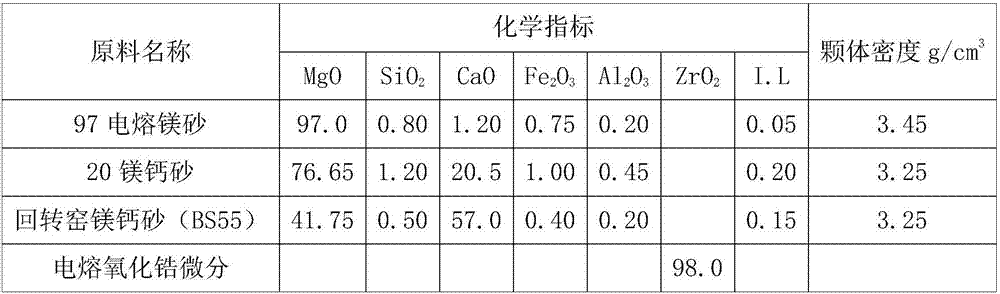

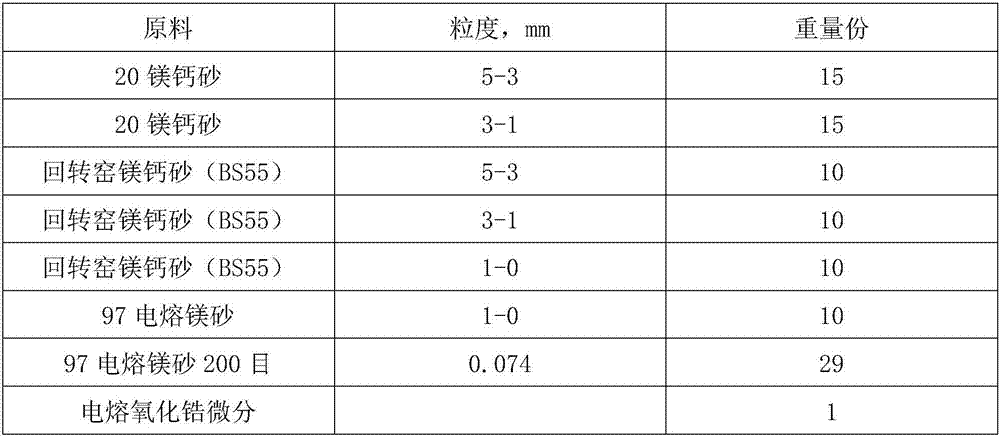

[0039] See Table 2 for the ratio of raw materials for unburned magnesia-calcium-zirconium bricks without free carbon

[0040] Table 2 Example 1 preparation formula

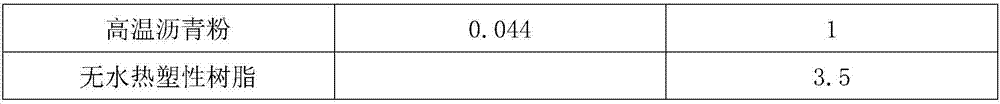

[0041]

[0042]

[0043] A method for producing unburned magnesia-calcium-zirconium bricks without free carbon, the specific steps are as follows:

[0044] 1) Crushing, screening and fine grinding of raw materials:

[0045] 97 fused magnesia is crushed and finely ground into 0-1mm, 200 mesh;

[0046] 20 magnesia-calcium sand is crushed and sieved into 3-5mm and 1-3mm;

[0047] Rotary kiln magnesia calcium sand (BS55) is screened into 3-5mm, 1-3mm, 0-1mm;

[0048] 2) Ingredients:

[0049] Weigh the raw materials according to the formula, and pre-mix 1-3 parts of capacitance zirconia differential, high-temperature asphalt powder and 0-1mm 97 fused magnesia to form a premix;

[0050] 3) Mixing:

[0051] First add 3-5mm, 1-3mm, 0-1mm particle size materials, dry mix for 3 minutes, then add binder anhydrous...

Embodiment 2

[0067] See Table 3 for the ratio of raw materials for unburned magnesia-calcium-zirconium bricks without free carbon

[0068] Table 3 Example 2 preparation formula

[0069] raw material

Granularity, mm

parts by weight

20 magnesia calcium sand

3-5

12

20 magnesia calcium sand

1-3

15

Rotary kiln magnesia calcium sand (BS55)

3-5

12

Rotary kiln magnesia calcium sand (BS55)

1-3

10

Rotary kiln magnesia calcium sand (BS55)

0-1

15

97 fused magnesia

0-1

10

97 fused magnesia 200 mesh

0.074

30

Fused Zirconia Differential

1.5

High temperature asphalt powder

0.044

1

Anhydrous thermoplastic resin

3.8

[0070] A method for producing unburned magnesia-calcium-zirconium bricks without free carbon, the specific steps are as follows:

[0071] 1) Crushing, screening and fine grinding of raw materials:

[0072] 97 fused magnesia is crushed and fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com