Preparation method of HEDP copper-plated non-porous thin layer

A technology of porosity and thin layer, which is applied in the field of preparation of non-porous thin layer of HEDP copper plating, can solve the problems of slow deposition speed, cracking of plating solution performance, low porosity, etc., and achieve good economic and social benefits, bath maintenance Convenience and stable bath performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Substrate treatment: sand with 600#, 800#, 1000# sandpaper in sequence to remove floating rust on the surface; then carry out chemical degreasing, the composition of chemical degreasing liquid is: sodium hydroxide 70g / L, sodium carbonate 40g / L, phosphoric acid Trisodium 40g / L, sodium silicate 20g / L, temperature 80°C, time 20min; then wash with flowing warm water, flow cold water, deionized water, and then activate. The composition of the activation solution is: hydrochloric acid 25g / L, room temperature, time 90s ;Followed by flowing cold water washing, deionized water washing, and then neutralization, the neutralization liquid composition is: sodium carbonate 35g / L, room temperature, time 60s; then flowing cold water washing, deionized water washing;

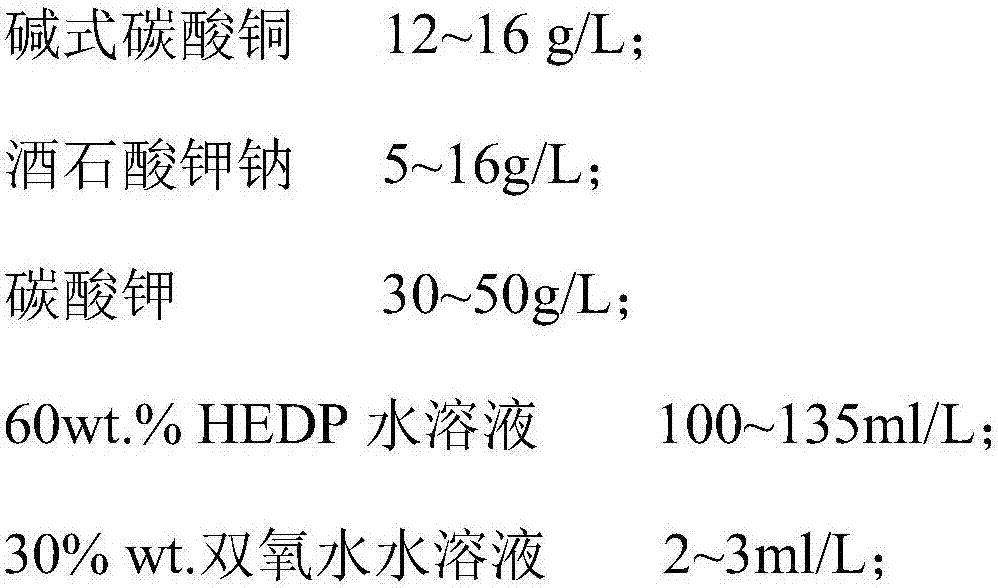

[0025] 2) Electroplating solution preparation: prepare 1L HEDP copper plating solution, its composition is as follows:

[0026] Basic copper carbonate 15g / L;

[0027] Sodium Potassium Tartrate 14g / L;

[0028] Potassi...

Embodiment 2

[0034] 1) Substrate treatment: sand with 600#, 800#, 1000# sandpaper in sequence to remove floating rust on the surface; then carry out chemical degreasing, the composition of chemical degreasing liquid is: sodium hydroxide 70g / L, sodium carbonate 40g / L, phosphoric acid Trisodium 40g / L, sodium silicate 20g / L, temperature 80°C, time 20min; then wash with flowing warm water, flow cold water, deionized water, and then activate. The composition of the activation solution is: hydrochloric acid 25g / L, room temperature, time 90s ;Followed by flowing cold water washing, deionized water washing, and then neutralization, the neutralization liquid composition is: sodium carbonate 35g / L, room temperature, time 60s; then flowing cold water washing, deionized water washing;

[0035] 2) Electroplating solution preparation: prepare 1L HEDP copper plating solution, its composition is as follows:

[0036] Basic copper carbonate 15g / L;

[0037] Sodium Potassium Tartrate 14g / L;

[0038] Potassi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com