Method for suppressing coking and carbonizing for hydrocarbons steam cracking unit

A cracking device and steam technology, applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., can solve the problems of shortening the service life of furnace tubes, reducing ethylene production, difficult maintenance, etc. Effect of carbon and performance deterioration, simple and easy operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 and embodiment 2 are the result that industrial cracking furnace is processed.

[0040] Example 1

[0041] Set the solid content to 20%, SiO 2 / Al 2 o 3 =8, PH is that the aluminum silicate sol of 3~4 is diluted with water to be the SiO that oxide mass concentration is 1% 2 —Al 2 0 3 Aqueous solution of sol. The device is a 60,000 tons / year ethylene SRT-IV industrial cracking furnace, which is divided into six groups of feed materials, and three waste heat boilers are connected in parallel. During the hot standby period after the cracking furnace is burnt, the outlet temperature of the cracking furnace is 700-850°C. Under the operating pressure of 0.4Mpa, the diluted SiO 2 —Al 2 o 3 The sol aqueous solution is injected from the convection section of the cracking furnace accompanied by carrier gas water vapor (20kg / h), the injection amount is 2.0kg / h, and the injection time is 3 hours. Si0 2 —Al 2 o 3 The sol forms a layer of ceramic film on t...

Embodiment 2

[0043] Set the solid content to 20%, SiO 2 / Al 2 o 3 =8, PH is that the aluminum silicate sol of 3~4 is diluted with water to be the SiO that oxide mass concentration is 2% 2 —Al 2 o 3 Aqueous solution of sol. The device is a 30,000-ton ethylene / year GK-V cracking furnace, which is divided into four groups of feed materials and has two waste heat boilers. During the hot standby period after the cracking furnace is burnt, the outlet temperature of the cracking furnace is 700-850 °C. Under the operating pressure of 0.3Mpa, the diluted SiO 2 —Al 2 o 3 The sol aqueous solution is injected from the spanning section of the cracking furnace accompanied by carrier gas water vapor (10kg / h), the injection amount is 1.5kg / h, and the injection time is 2 hours. SiO 2 —Al 2 o 3 The sol forms a layer of ceramic film on the inner wall of the cracking furnace tube, which can inhibit the coking and carburizing of the furnace tube. Steam cracking is carried out after the cracking fur...

Embodiment 3

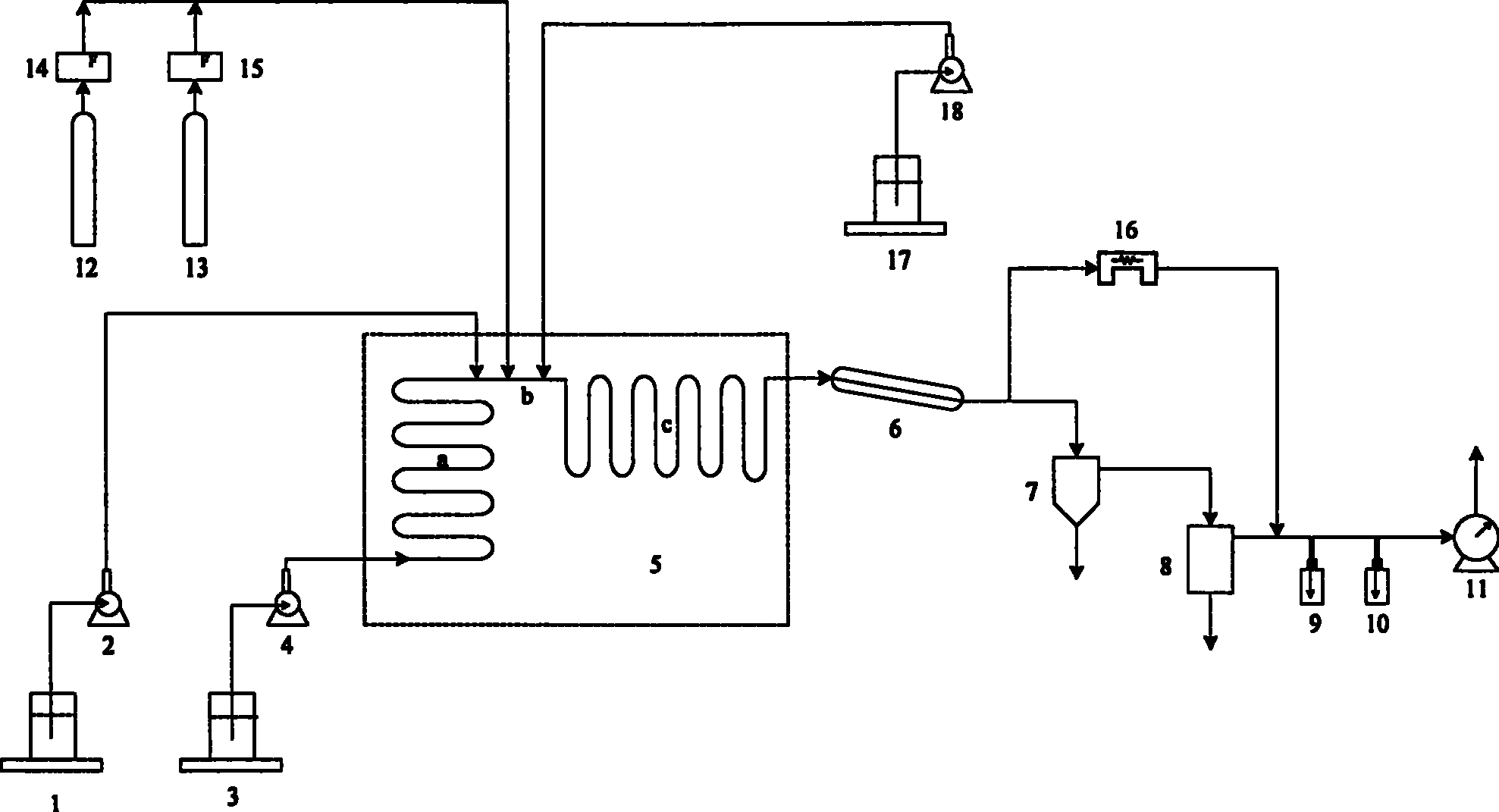

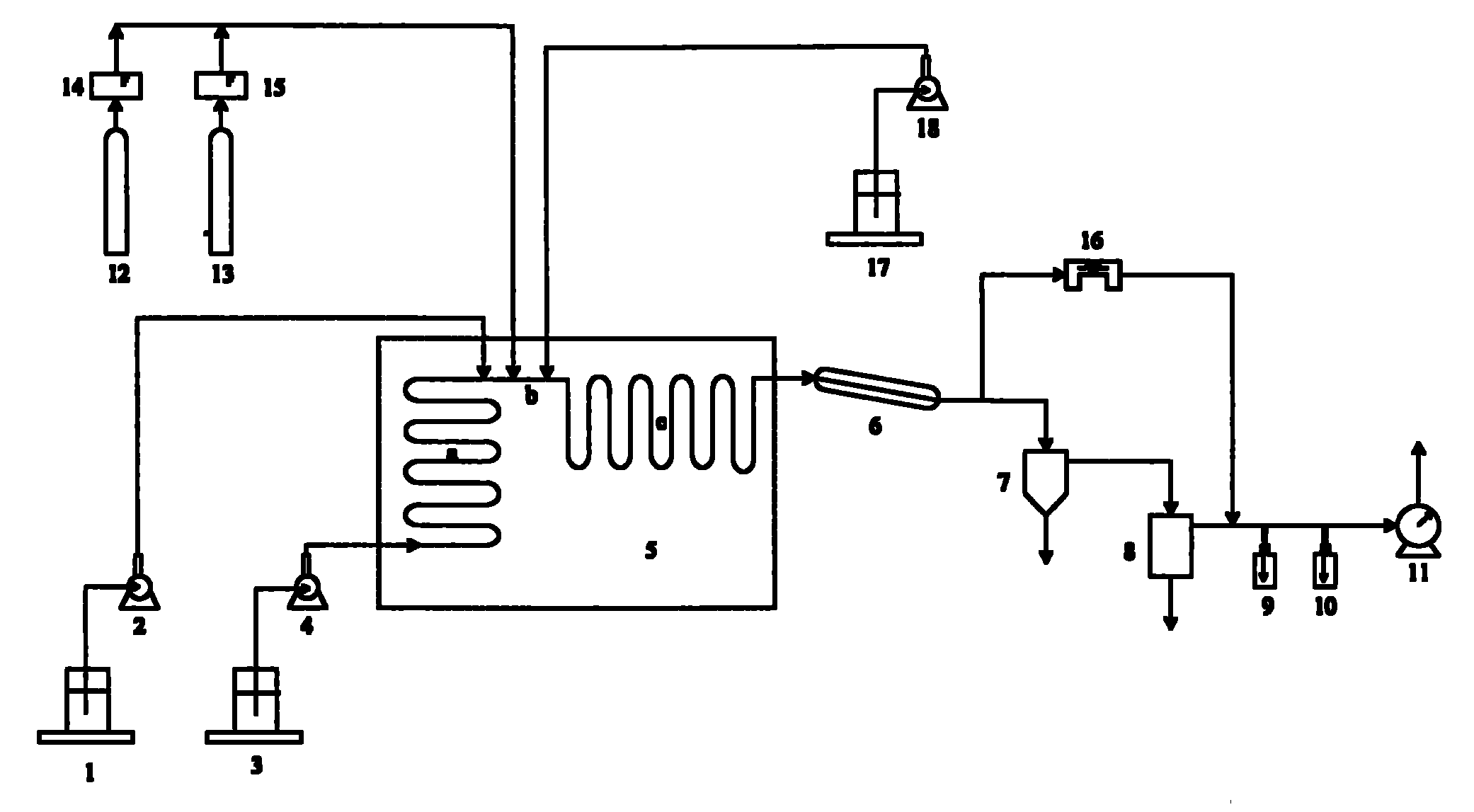

[0051] Simulate the SRT-III type cracking furnace, adopt the method of the present invention, when the outlet temperature of the cracking furnace is 800°C, SiO 2 Neutral silica sol with a mass concentration of 20% and a pH of 6.5 to 7.5 is diluted with water to SiO with a mass concentration of 0.5% pure oxide 2 Aqueous sol solution is injected from the spanning section of the cracking furnace, the injection amount is 200g / h, and the injection time is 1 hour, SiO 2 The sol forms a layer of ceramic film on the inner wall of the cracking furnace tube, which can inhibit the coking and carburizing of the furnace tube. After using the above method to treat the cracking furnace tube, steam cracking is carried out with naphtha as raw material. The cracking conditions are: cracking temperature 840°C, residence time 0.37 seconds, feed oil amount 800g / h, water amount 400g / h, water oil Ratio 0.5, reaction time 6 hours. The amount of coking in the simulated cracking furnace is 3.48g, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com