A kind of production process of environment-friendly high grammage paper towel

A production process and technology of paper towel, applied in papermaking, paper machine, textile and papermaking, etc., can solve the problems of unsolved softness and complex production process, achieve stable pulp quality, improve operation efficiency and reduce pulp cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

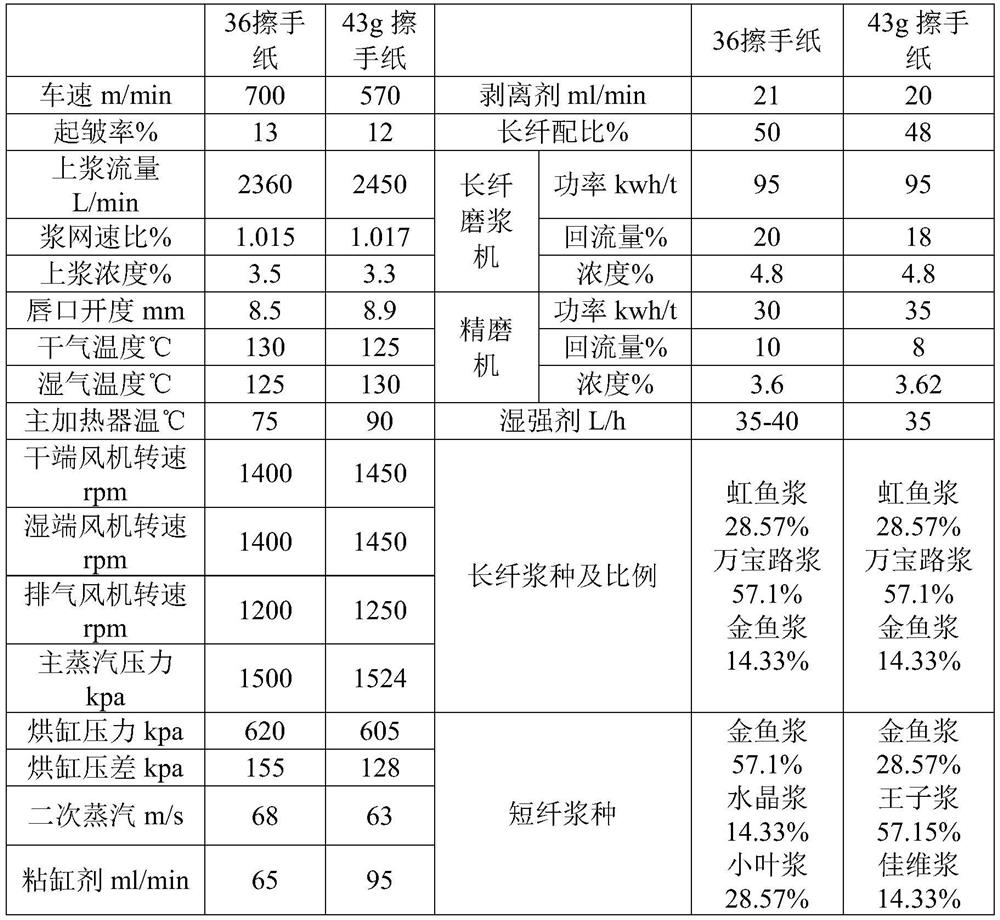

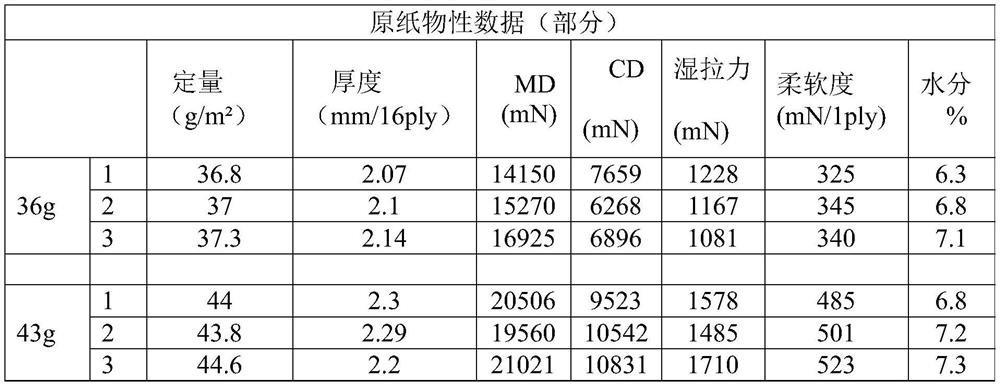

[0035] A workshop metos DCT135+ paper machine makes 36g / m 2 and 43g / m 2 Process parameters and physical property data of paper towels:

[0036]

[0037]

[0038] The physical properties of the base paper are all within the standard requirements of the formula card. At the same time, the production is stable and there are no phenomena such as large fluctuations in the moisture content of the base paper, wet paper sheets not being loaded into the vat, and poor forming.

Embodiment 2

[0040] An environment-friendly high-grammage paper towel production process adopts the following steps:

[0041] (1) pulp preparation process:

[0042] (1-1) Carry out pulping treatment to the commercially available rainbow fish slurry, and the pulping concentration obtained is 6wt%;

[0043] (1-2) Put the pulp after the pulping treatment in a refiner for refining treatment, use a long fiber refiner and a refiner for two refining, and control the concentration of the pulp in the long fiber refiner It is 4.8wt%, the slurry flow return rate is 15%, the knocking degree is 20SR, the power of the long fiber refiner is 90kwh / t, the control slurry concentration in the refiner is 3.5wt%, the slurry flow return rate is 8%, the beating degree is 28SR, and the power of the refiner is 35kwh / t;

[0044] (1-3) Add broken paper to the long-fiber pulp obtained after the refining treatment, the absolute-dry dosage ratio of the long-fiber pulp is 45wt%, and the absolute-dry dosage ratio of th...

Embodiment 3

[0052] An environment-friendly high-grammage paper towel production process adopts the following steps:

[0053] (1) pulp preparation process:

[0054] (1-1) The commercially available Marlboro slurry is crushed, and 14wt% of the leaflet slurry and 15wt% of the crystal slurry are added to obtain a pulp concentration of 6wt%;

[0055] (1-2) Put the pulp after the pulping treatment in a refiner for refining treatment, use a long fiber refiner and a refiner for two refining, and control the concentration of the pulp in the long fiber refiner It is 4.9wt%, and the slurry flow return rate is 18%, and the beating degree is 22SR. 10%, the beating degree is 30SR, and the power of the refiner is 40kwh / t;

[0056] (1-3) Add broken paper to the long-fiber pulp obtained after the refining treatment, the dry-dry dosage ratio of the long-fiber pulp is 50wt%, and the concentration of the added broken paper dry-dry dosage ratio in the pulp It is 20wt%, the preparation obtains slurry;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com