Light filtration medium for water treatment and preparation method and application thereof

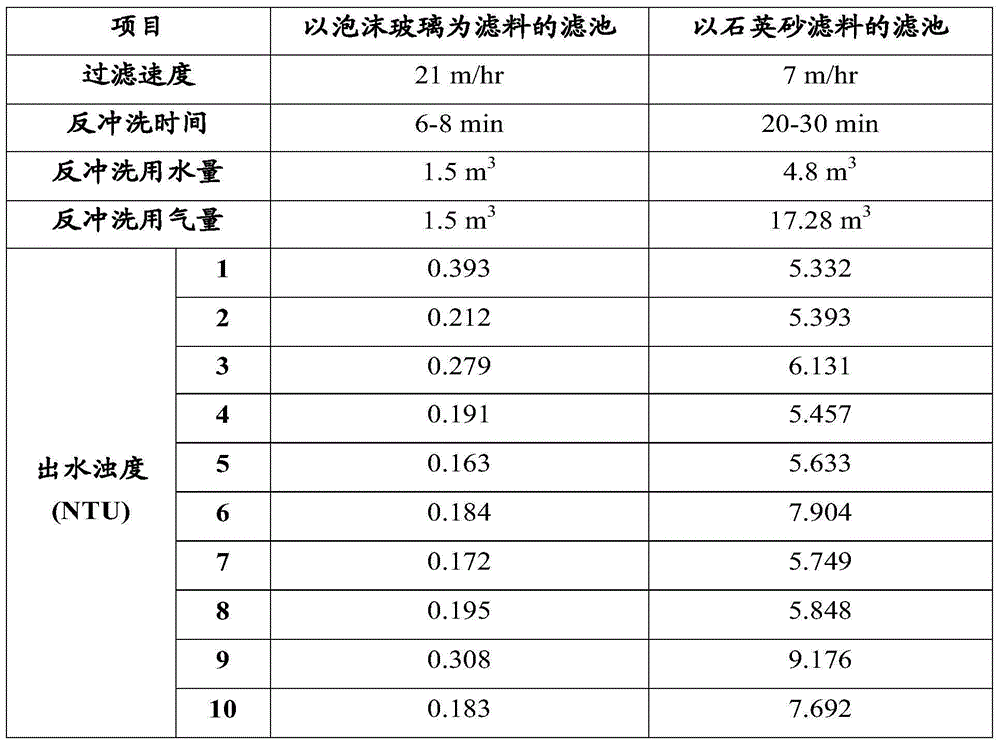

A filter medium and water treatment technology, which is applied in the field of lightweight filter medium for water treatment and its preparation, can solve the problems of long sewage treatment process, short filtration cycle, low void ratio of quartz sand filter material, etc., and reduce backwash Time and water consumption, large filtration capacity, and the effect of saving backwashing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

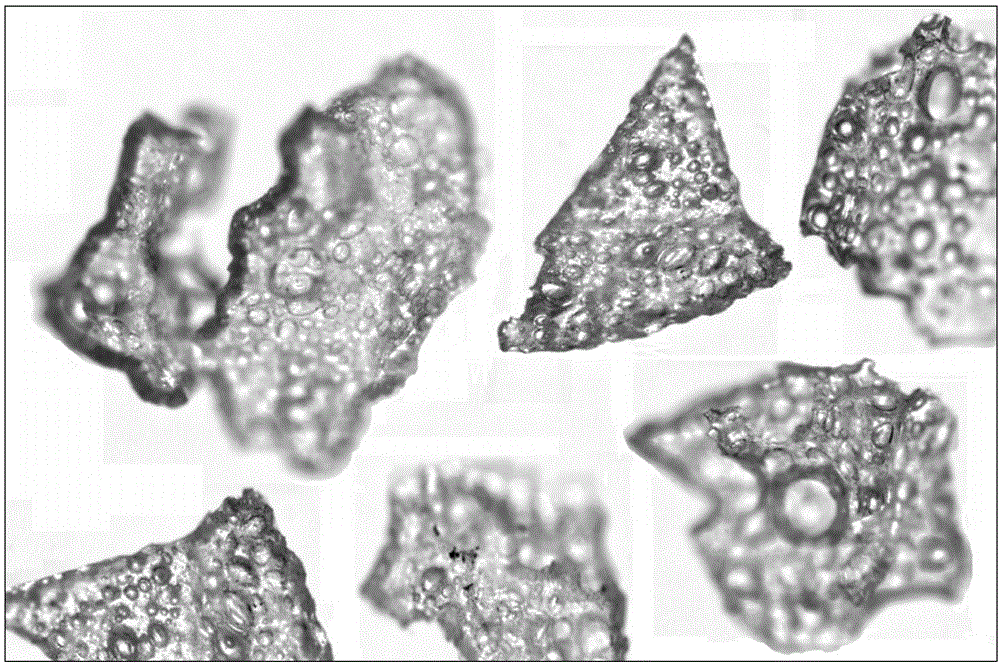

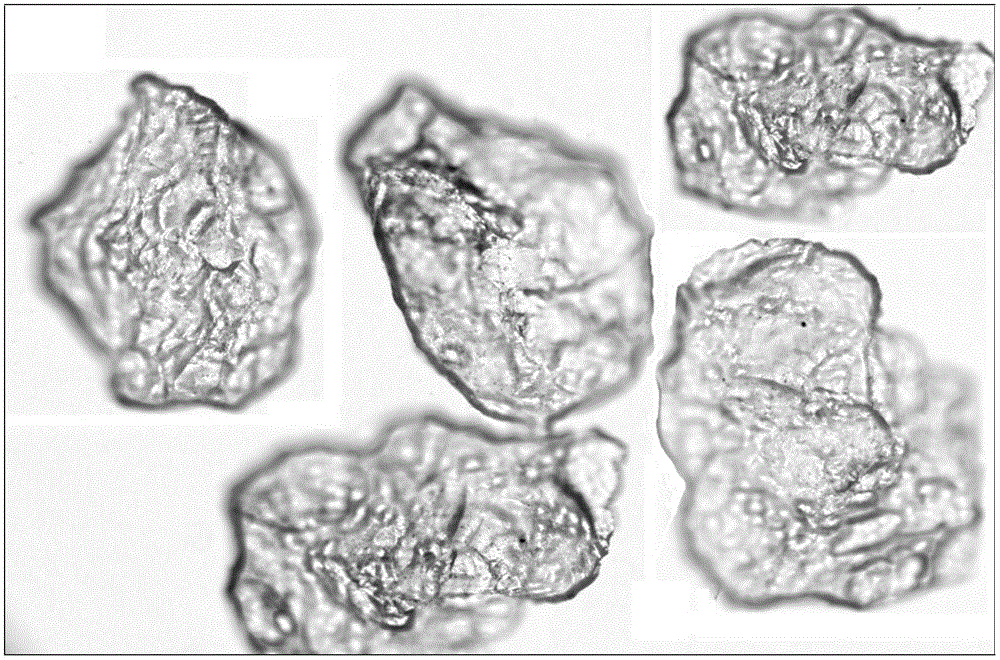

[0060] After adding foaming agent (magnesium carbonate or sodium bicarbonate), foaming agent accelerator (borax) and modifying agent (barium sulfate) to fine glass powder (purchased directly, the particle size is about 400 μm), mix well to obtain mixed raw materials;

[0061] The mixed raw materials are melted and foamed (not lower than 600°C), then cooled, pulverized and screened in sequence to obtain foam glass that can be used as a light filter medium for water treatment.

Embodiment 2

[0063] Crushing waste glass to obtain 3-5mm glass shards, and crushing the glass shards into fine glass powder with a particle size of 100-400 μm;

[0064] After adding 2 parts of foaming agent (carbon black), 1 part of foaming agent accelerator (sodium nitrate) and modifying agent (sodium pyrophosphate) to 97 parts by weight of fine glass powder, mix evenly to obtain mixed raw materials;

[0065] After the mixed raw materials are melted and foamed, they are sequentially cooled and pulverized again to obtain foam glass; wherein, during the process of melting and foaming, the melting and foaming furnace is raised to 600°C at a rate of 10°C / min, and foamed for 3-4 Hour.

Embodiment 3

[0067] Crushing waste glass to obtain 3-5mm glass shards, and using a pulverizer to crush the glass shards into fine glass powder with a particle size of 100-400 μm;

[0068] After adding 3 parts of foaming agent (silicon carbide), 2 parts of foaming agent accelerator (sodium fluorosilicate) and modifier (antimony trioxide) to 95 parts by weight of fine glass powder (in equal proportions), the Mix well to obtain mixed raw materials;

[0069] After the mixed raw materials are melted and foamed, they are naturally cooled and pulverized again (with a particle size of 0.5-1.0 mm) to obtain foam glass; wherein, during the process of melting and foaming, the melting and foaming furnace is raised to 1000°C, and foam for 2-3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com