High-temperature 260 DEG C resistant tightly-packaged fiber and preparation process thereof

A technology of tight-packed optical fiber and high temperature resistance, which is applied in the direction of clad optical fiber, multi-layer core/clad optical fiber, etc., to achieve the effects of improving heat resistance, environmental resistance, and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

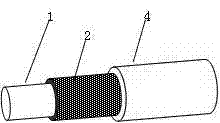

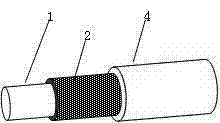

[0009] Control attached figure 1 , its structure is that the periphery of the fiber core 1 is a polyimide coating layer 2 coated with coating equipment; Tight outer layer 4 of polytetrafluoroethylene material (PFA).

[0010] Its preparation process, optical fiber core is divided into single-mode and multi-mode, typical specifications are: single-mode structure 9 / 125μm, multi-mode structure 50 / 125μm or 62.5 / 125μm; coating layer is coated with polyimide by coating equipment , the temperature resistance grade of polyimide is -65℃~+260℃, and the outer diameter of the coating layer is 155μm. The coating layer enables the normal laying and installation of tight-packed optical fibers at -65℃; The soluble polytetrafluoroethylene material (PFA) extruded by machine single-layer thin-wall, and the outer layer of the tight wrap can withstand high temperature of 260°C.

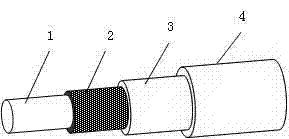

[0011] Control attached figure 2 , the structure is that the periphery of the fiber core 1 is coated with polyimide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com