Method and machine tool for machining and hardening metallic workpieces

A technology for metal workpieces and workpieces, applied in the field of machining and hardening metal workpieces, can solve problems such as reprocessing and lowering of processing quality, and achieve the effects of saving costs, shortening processing time, and high cutting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

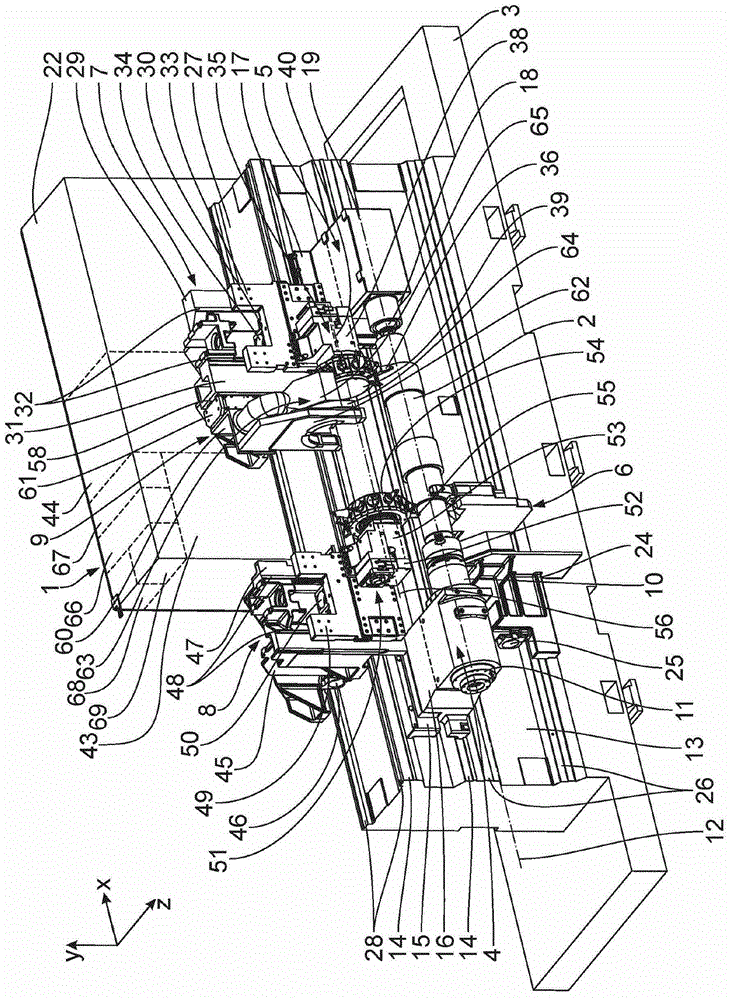

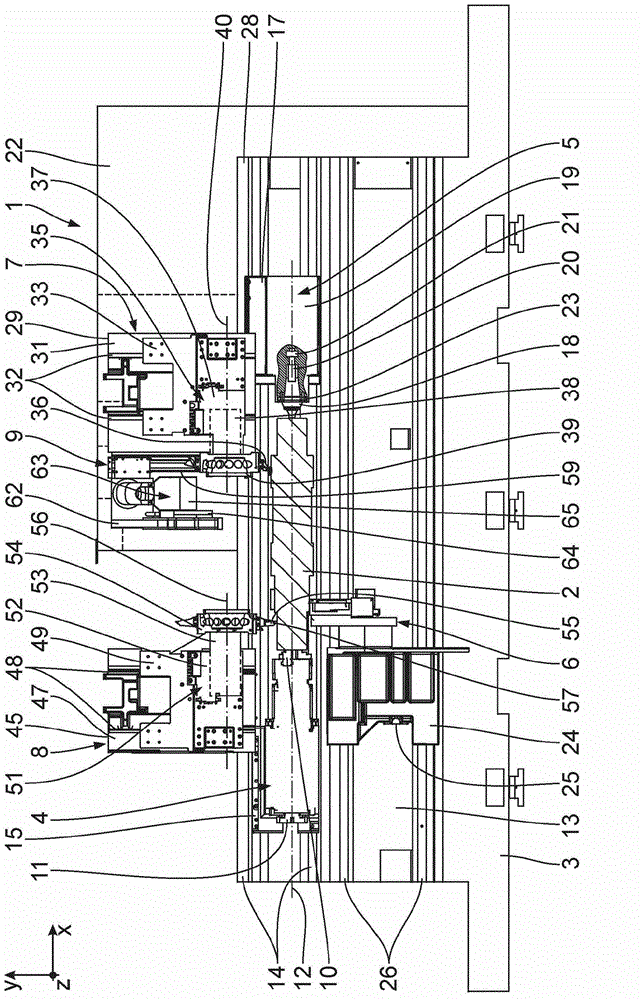

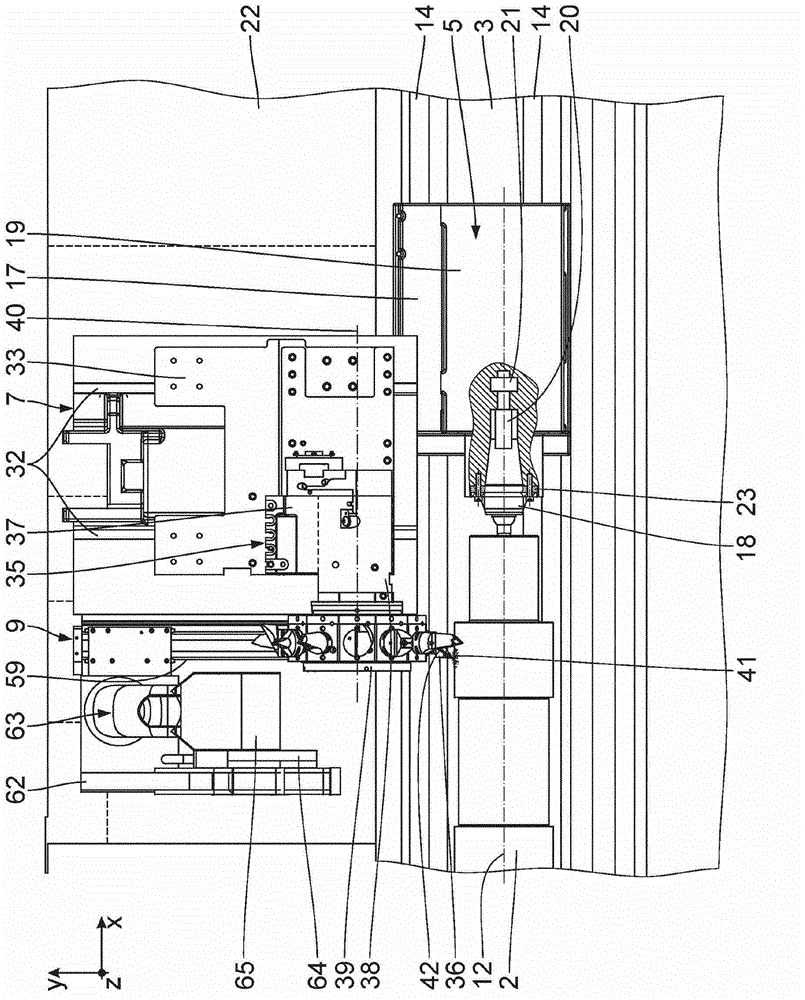

[0029] For producing a hardened shaft-shaped workpiece 2 made of metal, the machine tool 1 has a base frame 3 on which three workpiece holders 4 to 6 and two machining devices 7 , 8 and a hardening device 9 are arranged.

[0030] The first workpiece holder 4 is designed as a workpiece spindle and has a chuck 10 which can be driven in rotation by means of a spindle drive motor 11 about an axis of rotation 12 extending parallel to the x-direction. The workpiece spindle 4 is arranged on the front face 13 of the base frame 3 and is linearly displaceable parallel to the x-direction. For this purpose, on the front face 13 , first x-guides 14 are arranged spaced apart from one another in the y-direction extending perpendicularly to the x-direction, on which guides the workpiece spindle 4 is mounted by means of a first x-slide 15 . The x-slide 15 can be moved linearly along the x-rail 14 by means of a first x-drive motor 16 .

[0031] The second workpiece holder 5 is mounted on the x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com