High temperature resistance multimode special optical fiber for aviation and manufacturing method thereof

A high temperature resistant and aviation technology, applied in the direction of fiber mechanical structure, etc., to achieve the effect of high flame retardant performance, round and stable structure, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Its preparation method includes the following processes:

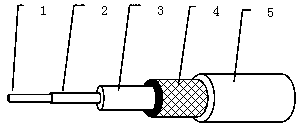

[0029] 1) The fiber core is multimode, and the structure is divided into 50 / 125μm and 62.5 / 125μm;

[0030] 2) Use coating equipment to coat high temperature-resistant -55℃~+125℃ UV-curable acrylate on the periphery of the fiber core as a coating layer, temperature-resistant -55℃~+125℃, and the outer diameter of the coating layer is 245μm ;

[0031] 3) Single-layer or double-layer extruded ethylene tetrafluoroethylene copolymer materials are used by high-temperature extruders, and wrapped around the coating layer as a tight cladding layer 3, with a temperature resistance of -55°C to +125°C;

[0032] 4) Use a high-speed braiding machine to weave aramid fiber, and wrap it around the outer edge of the tight cladding 3 as the reinforcement layer 4, meeting the tensile strength of 150N;

[0033] 5) Use a high-temperature extruder to extrude ethylene tetrafluoroethylene copolymer, and wrap it around the reinforcement...

example

[0034] Typical example: the outer diameter of the optical cable is 1.8mm, the outer diameter of the tight cladding is 0.9mm, the core structure is 62.5μm / 125μm, and the high temperature resistant multimode optical cable for aviation is 125°C, expressed as GTAE125-62.5 / 125-0.9-1.8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com