Elevator roller rubber compound for vertical elevator and preparation technology

A technology of vertical lifting and manufacturing process, which is applied in the field of elevator rollers, an important component, can solve the problems of roller parts relying on imports, short service life, large deformation, etc., to achieve localization, improve flex resistance, and improve fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

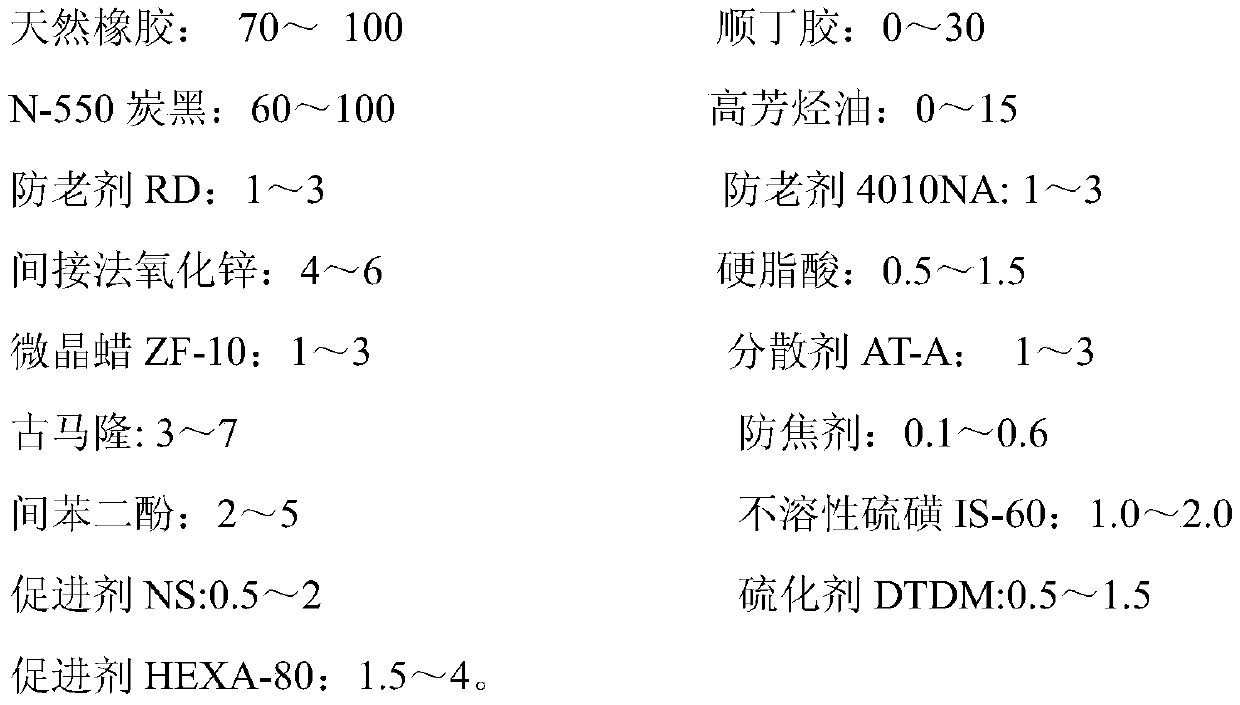

[0030] Elevator roller compound rubber formula is proportioned by weight as follows:

[0031]

[0032]

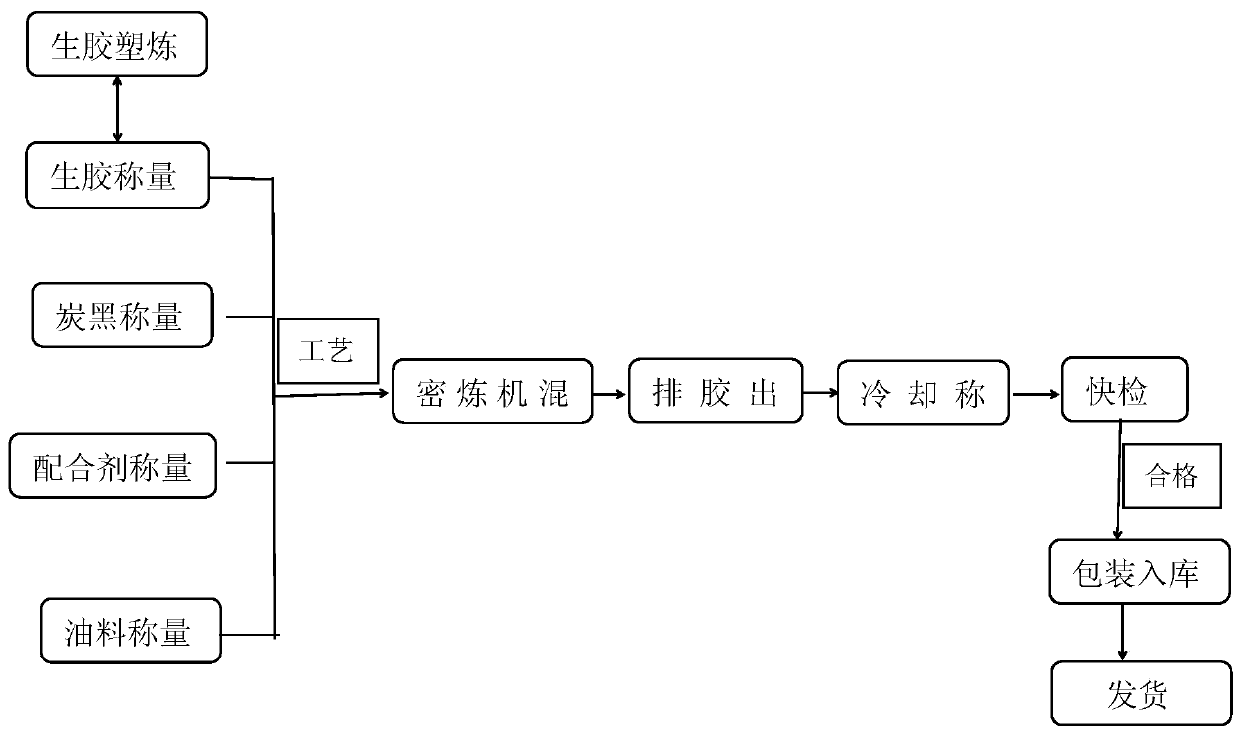

[0033] The manufacturing process steps of elevator roller compound rubber are as follows:

[0034] (1) carry out test production preparation according to the formula design scheme of the elevator roller rubber compound described in embodiment one, and make a record;

[0035] (2) Formulate the rubber mixing process steps, add different prepared raw materials into the internal mixer step by step, follow the specific process steps, the internal mixer pressure is 5.5MPa, the internal mixing time is 300 seconds, and the glue discharge temperature is 110°C , so that the raw materials of each component are mixed evenly;

[0036] (3) Detect the physical and mechanical properties of the mixed rubber, such as hardness, strength, elongation, especially the compression deformation of the rubber;

[0037] (4) Judgment of results, the results obtained in step (3) are judged accor...

Embodiment 2

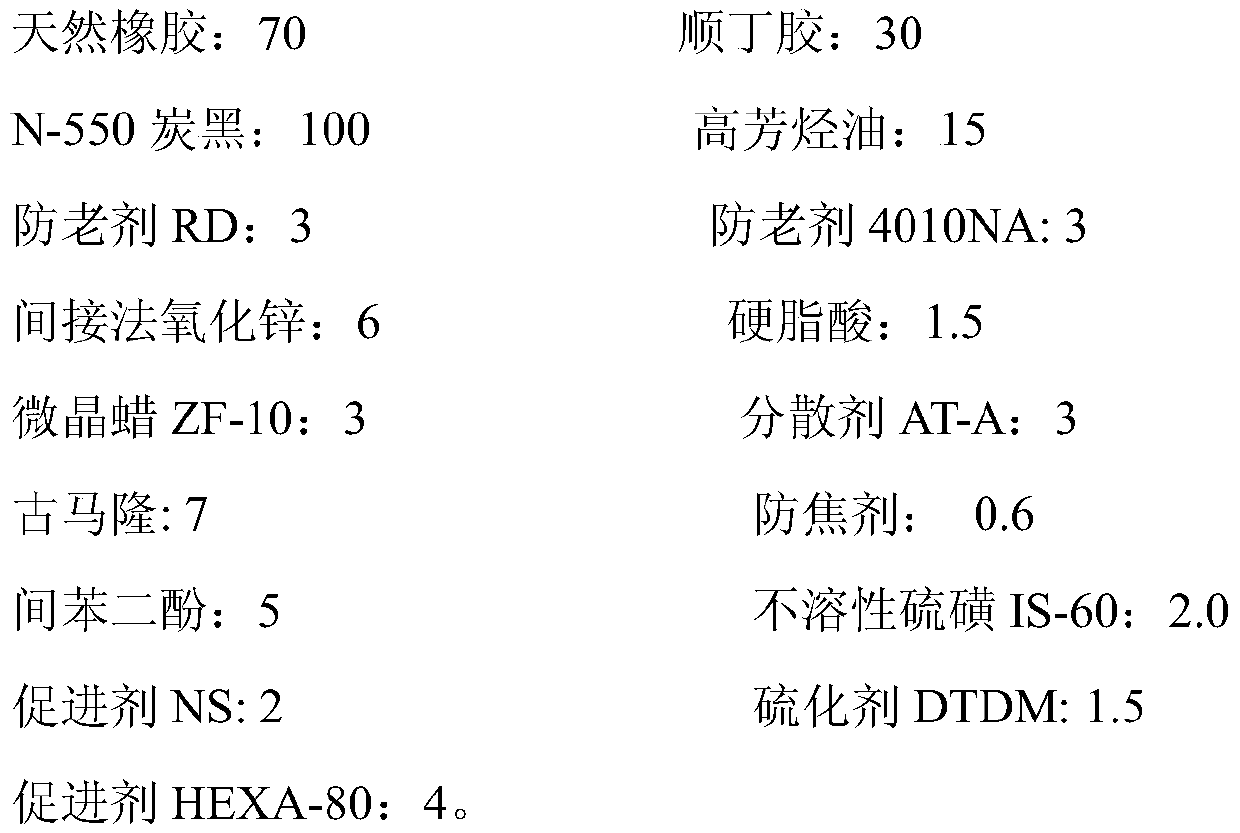

[0040] Elevator roller compound rubber formula is proportioned by weight as follows:

[0041]

[0042] The manufacturing process steps of elevator roller compound rubber are as follows:

[0043] (1) carry out test production preparation according to the formula design scheme of the elevator roller rubber compound described in embodiment two, and make a record;

[0044] (2) Formulate the rubber mixing process steps, add different prepared raw materials into the internal mixer step by step, the pressure of the internal mixer is 5.5MPa, the internal mixing time is 360 seconds, and the rubber discharge temperature is 110°C, so that each component Raw materials are mixed evenly;

[0045] (3) Detect the physical and mechanical properties of the mixed rubber, such as hardness, strength, elongation, especially the compression deformation of the rubber;

[0046] (4) Judgment of results, the results obtained in step (3) are judged according to the requirements of standard indicator...

Embodiment 3

[0049] Elevator roller compound rubber formula is proportioned by weight as follows:

[0050]

[0051] The manufacturing process steps of elevator roller compound rubber are as follows:

[0052] (1) carry out test production preparation according to the formula design scheme of the elevator roller described in embodiment three, and make a good record;

[0053] (2) Formulate the rubber mixing process steps, add different prepared raw materials into the internal mixer step by step, the pressure of the internal mixer is 5.5MPa, the internal mixing time is 420 seconds, and the rubber discharge temperature is 115°C, so that each component Raw materials are mixed evenly;

[0054] (3) Detect the physical and mechanical properties of the mixed rubber, such as hardness, strength, elongation, especially the compression deformation of the rubber;

[0055] (4) Judgment of the result, the result obtained in step (3) is judged according to the standard index requirements, and the quali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com