Waterborne polyurethane leather finishing agent and preparation method thereof

A technology of water-based polyurethane and leather finishing agent, applied in polyurea/polyurethane coating, leather surface treatment, small raw hide/large raw hide/leather/fur treatment, etc. Excellent light resistance, improved selection rate, and soft hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

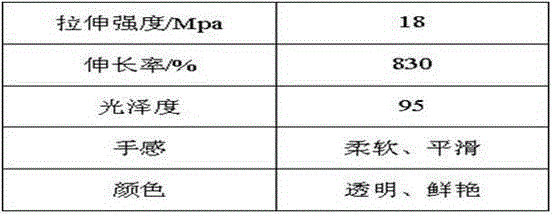

[0029] In parts by weight, under the protection of nitrogen, react 10 parts of CAB, 40 parts of PTMG-2000, and 35 parts of IPDI at 80-85°C for 2-3h, add 5 parts of DMPA, and continue at 80-85°C React for 3-5 hours, lower the temperature to 40°C, add 4 parts of triethylamine, react for 30 minutes, and disperse with water at high speed, then add 6 parts of ethylenediamine and disperse for 1 hour to obtain a CAB modified waterborne polyurethane dispersion. The typical characteristics of its products are as follows:

[0030]

Embodiment 2

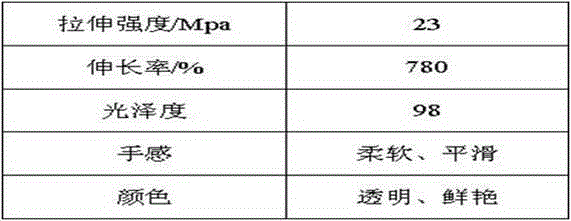

[0032] In parts by weight, under the protection of nitrogen, react 15 parts of CAB, 35 parts of PTMG-2000, and 40 parts of IPDI at 80-85°C for 2-3h, add 5 parts of DMPA, and continue at 80-85°C React for 3-5 hours, lower the temperature to 40°C, add 4 parts of triethylamine, react for 30 minutes, and disperse at high speed with water, then add 6.3 parts of ethylenediamine and disperse for 0.5 hours to obtain a CAB modified waterborne polyurethane dispersion. The typical characteristics of its products are as follows:

[0033]

Embodiment 3

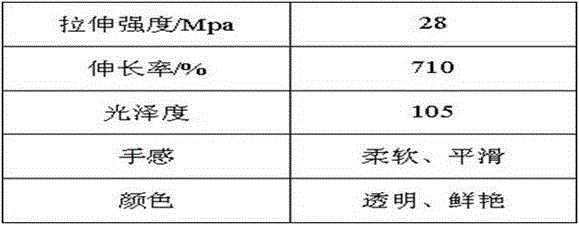

[0035] In parts by weight, under the protection of nitrogen, react 20 parts of CAB, 30 parts of PTMG-2000, and 40 parts of IPDI at 80-85°C for 2-3 hours, add DMPA, and continue the reaction at 80-85°C After 3-5 hours, cool down to 40°C, add 4 parts of triethylamine, react for 30 minutes, and disperse at high speed with water, then add 5 parts of ethylenediamine and disperse for 1 hour to obtain CAB modified waterborne polyurethane dispersion. The typical characteristics of its products are as follows:

[0036]

[0037] The invention provides a water-based polyurethane leather finishing agent and a preparation method thereof. The water-based polyurethane is modified by using cellulose acetate butyrate to obtain a CAB modified water-based polyurethane dispersion. The resin film is bright, tough, good flex resistance, endows leather with excellent high gloss, smooth, soft feel and good ironing performance, as well as excellent light resistance, heat resistance, non-yellowing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com