Polyurethane modified asphalt waterproof roll and production method thereof

A kind of asphalt waterproof membrane, polyurethane modification technology, applied in the direction of chemical instruments and methods, hydraulic material layered products, layered products, etc., can solve the problem of polymer material performance degradation, modified asphalt membrane tensile strength It can improve the water resistance and scratch resistance, excellent storage stability, and improve the effect of anti-mold performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

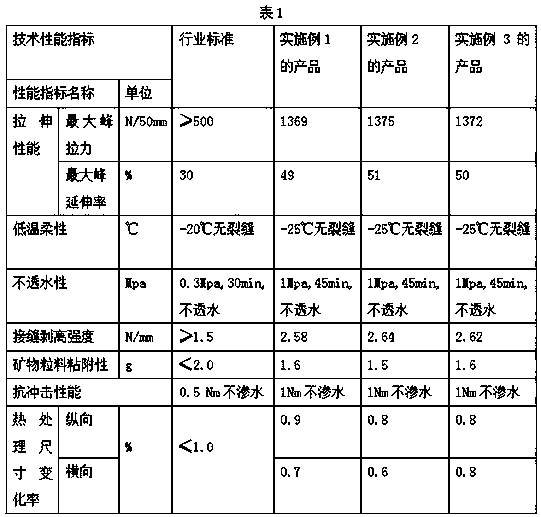

Examples

Embodiment 1

[0030] A polyurethane modified asphalt waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: upper surface isolation layer, upper modified asphalt layer, base layer, lower modified asphalt layer and lower surface isolation layer;

[0031] The upper surface isolation layer and the lower surface isolation layer are made of polyethylene film; the base layer is made of polyester fiber non-woven fabric;

[0032] The upper modified asphalt layer and the lower modified asphalt layer are made of polyurethane modified asphalt, and the polyurethane modified asphalt is made of the following raw materials in parts by weight: 65 parts of 90# petroleum asphalt; 15 parts of naphthenic oil ; 15 parts of SBR styrene-butadiene rubber; 1 part of tri-tert-butoxy vinyl silane; 8 parts of polyurethane prepolymer; 5 parts of polyvinyl alcohol; 2 parts of softener dibutyl fumarate; antioxidant tert-butyl p- 1 part of hydroquinone; 0.1 part of ultraviolet absorbe...

Embodiment 2

[0043] A polyurethane modified asphalt waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: upper surface isolation layer, upper modified asphalt layer, base layer, lower modified asphalt layer and lower surface isolation layer;

[0044] The upper surface isolation layer is coated sand, the lower surface isolation layer is polyethylene film; the base layer is HDPE film;

[0045] The upper modified asphalt layer and the lower modified asphalt layer are made of polyurethane modified asphalt, and the polyurethane modified asphalt is made of the following raw materials in parts by weight: 68 parts of 90# petroleum asphalt; 17 parts of naphthenic oil ; 16 parts of SBR styrene-butadiene rubber; 2 parts of tri-tert-butoxy vinyl silane; 9 parts of polyurethane prepolymer; 7 parts of polyvinyl alcohol, 3 parts of softener dibutyl fumarate; 1.5 parts of hydroquinone; 0.2 parts of ultraviolet absorber UV-531; 3 parts of acetyl tri-n-butyl citrate; ...

Embodiment 3

[0056] A polyurethane modified asphalt waterproof membrane, the waterproof membrane is a five-layer structure, from top to bottom: upper surface isolation layer, upper modified asphalt layer, base layer, lower modified asphalt layer and lower surface isolation layer;

[0057] The upper surface isolation layer is polyester isolation film, the lower surface isolation layer is polyethylene film; the base layer is glass fiber felt or glass fiber reinforced polyester felt;

[0058] The upper modified asphalt layer and the lower modified asphalt layer are made of polyurethane modified asphalt, and the polyurethane modified asphalt is made of the following raw materials in parts by weight: 70 parts of 90# petroleum asphalt; 20 parts of naphthenic oil ; 20 parts of SBR styrene-butadiene rubber; 3 parts of tri-tert-butoxy vinyl silane; 10 parts of polyurethane prepolymer; 8 parts of polyvinyl alcohol, 4 parts of softener dibutyl fumarate; 2 parts of hydroquinone; 0.3 parts of ultraviole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com