Catalyst and preparation method for catalytic hydrolysis of hydrogen cyanide

A technology for catalytic hydrolysis and catalyst, applied in catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of difficult experimental control and harsh preparation conditions, and achieve simple preparation technology and process, high active components The effect of dispersion and low activation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: The catalyst for the catalytic hydrolysis of hydrogen cyanide in this example is made from the following composition by weight: 93.2% carrier, 5% active component, 1% additive, and the balance is the outer layer of atomic deposition Titanium dioxide; wherein the carrier is titanium-silicon molecular sieve TS-1, the active component is iron oxide, and the auxiliary agent is yttrium oxide; by weight percentage, the content of Ti in the TS-1 molecular sieve is 2.5%;

[0025] A kind of preparation method for the catalyst of hydrogen cyanide catalytic hydrolysis, concrete steps are as follows:

[0026] (1) Preparation of TS-1 mesoporous molecular sieve carrier: mix tetraethyl orthosilicate and butyl titanate evenly to obtain mixed solution A, and drop it into tetrapropylammonium hydroxide aqueous solution under stirring condition to obtain mixed solution Solution B was reacted at a temperature of 50°C under stirring conditions for 30 minutes, then evaporated and r...

Embodiment 2

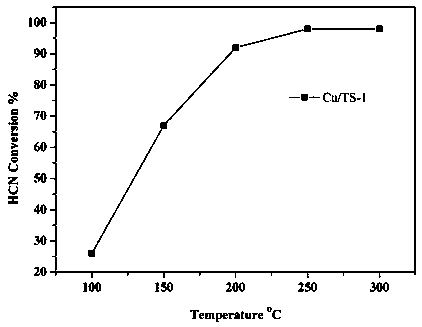

[0030]Example 2: The catalyst used for the catalytic hydrolysis of hydrogen cyanide in this example is made from the following composition by weight: 94.5% carrier, 4% active component, 0.5% additive, and the balance is the outer layer of atomic deposition Titanium dioxide; wherein the carrier is titanium-silicon molecular sieve TS-1, the active component is copper oxide, and the auxiliary agent is yttrium oxide; by weight percentage, the content of Ti in the TS-1 molecular sieve is 2.5%;

[0031] A kind of preparation method for the catalyst of hydrogen cyanide catalytic hydrolysis, concrete steps are as follows:

[0032] (1) Preparation of TS-1 mesoporous molecular sieve carrier: mix tetraethyl orthosilicate and butyl titanate evenly to obtain mixed solution A, and drop it into tetrapropylammonium hydroxide aqueous solution under stirring condition to obtain mixed solution Solution B reacted at 60°C for 48 minutes under stirring conditions, then evaporated and reacted at 70°...

Embodiment 3

[0036] Example 3: The catalyst for the catalytic hydrolysis of hydrogen cyanide in this example is made from the following composition in weight percentage: 91.8% carrier, 6% active component, 1% additive, and the balance is the outer layer of atomic deposition Titanium dioxide; wherein the carrier is titanium-silicon molecular sieve TS-1, the active components are copper oxide and iron oxide, the mass ratio of copper oxide and iron oxide is 1:1, and the auxiliary agent is magnesium oxide; by weight percentage, TS-1 The content of Ti in the molecular sieve is 1.0%;

[0037] A kind of preparation method for the catalyst of hydrogen cyanide catalytic hydrolysis, concrete steps are as follows:

[0038] (1) Preparation of TS-1 mesoporous molecular sieve carrier: mix tetraethyl orthosilicate and butyl titanate evenly to obtain mixed solution A, and drop it into tetrapropylammonium hydroxide aqueous solution under stirring condition to obtain mixed solution Solution B was reacted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com