Titanium dioxide-aluminum oxide composite desulfurization catalyst as well as preparation method and application thereof

A desulfurization catalyst, titanium dioxide technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Avoid the loss of active ingredients and the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

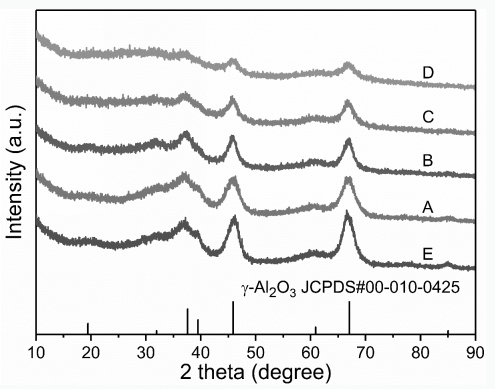

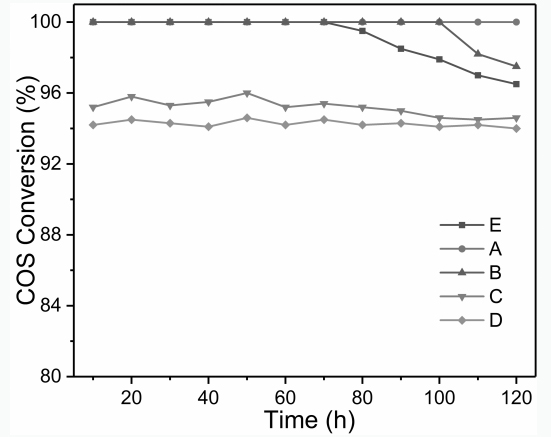

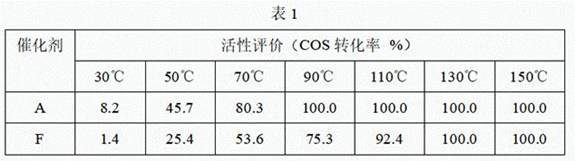

Embodiment 1

[0028] (1) Weigh 2.022g of aluminum isopropoxide and 0.034g of tetrabutyl titanate and dissolve them in a mixture of ethanol and nitric acid (50ml of ethanol, 2ml of nitric acid), fully stir until completely dissolved, and then add 1g of polyethylene glycol 4000, continue to stir until the solution is clear to obtain a mixed solution.

[0029] (2) Dissolve sodium hydroxide in deionized water to prepare a sodium hydroxide solution with a concentration of 3M.

[0030] (3) Slowly add sodium hydroxide solution dropwise to the mixed solution, adjust the pH of the mixed solution to 9, and let it stand for 16 hours.

[0031] (4) The aged precipitate was centrifuged and washed to neutrality, and dried at 60°C for 8h. The dried product was calcined in a muffle furnace at 600 °C for 4 h, and the heating rate was 3 °C / min to obtain sample A.

Embodiment 2

[0033] (1) Weigh 1.989g of aluminum isopropoxide and 0.085g of tetrabutyl titanate and dissolve them in a mixture of ethanol and nitric acid (50ml of ethanol, 2ml of nitric acid), fully stir until completely dissolved, and then add 1g of polyethylene glycol 4000, continue to stir until the solution is clear to obtain a mixed solution.

[0034] (2) Dissolve sodium hydroxide in deionized water to prepare a sodium hydroxide solution with a concentration of 3M.

[0035] (3) Slowly add sodium hydroxide solution dropwise to the mixed solution, adjust the pH of the mixed solution to 9, and let it stand for 16 hours.

[0036] (4) The aged precipitate was centrifuged and washed to neutrality, and dried at 60°C for 8h. The dried product was calcined in a muffle furnace at 600 °C for 4 h, and the heating rate was 3 °C / min to obtain sample B.

Embodiment 3

[0038] (1) Weigh 1.938g of aluminum isopropoxide and 0.17g of tetrabutyl titanate and dissolve them in a mixture of ethanol and nitric acid (50ml of ethanol, 2ml of nitric acid), fully stir until completely dissolved, and then add 1g of polyethylene glycol 4000, continue to stir until the solution is clear to obtain a mixed solution.

[0039] (2) Dissolve sodium hydroxide in deionized water to prepare a sodium hydroxide solution with a concentration of 3M.

[0040] (3) Slowly add sodium hydroxide solution dropwise to the mixed solution, adjust the pH of the mixed solution to 9, and let it stand for 16 hours.

[0041] (4) The aged precipitate was centrifuged and washed to neutrality, and dried at 60°C for 8h. The dried product was calcined in a muffle furnace at 600 °C for 4 h, and the heating rate was 3 °C / min to obtain sample C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com