Low-voltage flexible electrothermal film and preparation method therefor

An electric heating film, low voltage technology, applied in electric heating devices, ohmic resistance electrodes, ohmic resistance heating, etc., can solve the problems of discount of heat conduction and infrared radiation effect of electric heating film, high production cost, low yield rate, etc. The effect of large-scale industrial production, lowering the technical threshold and lowering the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

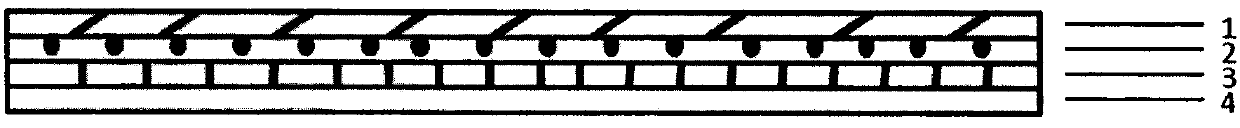

[0031] Screen-print a conductive heating layer on a PET film with a thickness of 100 μm, and dry it in a drying tunnel at a temperature of 100°C for 15 minutes. The resin in the conductive heating layer is polyurethane, and the filler is graphene. The content in the coating is 20wt%, the thickness of the conductive heating layer is 12 μm, and the square resistance of the coating is about 50Ω / square.

[0032] Screen print an electrode layer on the conductive heating layer, and dry it in a drying tunnel at a temperature of 110°C and a drying time of 15 minutes. The electrode layer is made of silver / graphene composite conductive paste. The electrode width is 1mm, the distance between adjacent inner electrodes is 7mm, the distance between the inner electrode and the outer pair electrode is 7mm, and the pattern of the printed electrodes is as follows Figure 4 shown.

[0033] Screen print a layer of heat conduction and infrared radiation layer on the electrode layer, and reserve a...

Embodiment 2

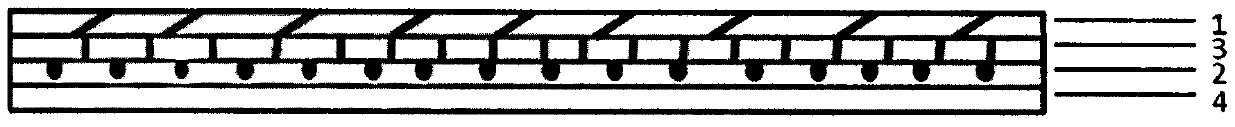

[0037] Screen-print an electrode layer on a PET film with a thickness of 100 μm, and dry it in a drying tunnel at a temperature of 110°C for 15 minutes. The electrode layer is made of silver / graphene composite conductive paste, and the width of the outer electrode is 8mm, the width of the inner electrode is 1mm, the distance between adjacent inner electrodes is 7mm, the distance between the inner electrode and the outer counter electrode is 7mm, the electrode layer of the whole electrothermal film is composed of four small units, each small unit The outer negative electrode is on the inner side, the outer positive electrode is on the outer side, and the pattern of the printed electrode is as follows: Figure 5 shown.

[0038] Screen print a layer of conductive heating layer on the electrode layer, and reserve a circular hole at the position of 1 / 2 of the outer electrode of each small unit, and dry it in the drying tunnel at a drying temperature of 100°C and a drying time of 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com