Common polyurethane flexible foam and preparation method thereof

A polyurethane, common technology, applied in the field of common polyurethane soft foam and its preparation, can solve the problems of insufficient compression set performance, poor sponge tear performance, sponge stiffness, etc. effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1.1 A preparation method of polyether polyol that assists in improving polyurethane tearing and compression set performance, comprising the steps:

[0048] 1. Add 41.36g glycerin and 20.68g trimethylolpropane into the closed reactor, replace the air in the reactor with nitrogen, and raise the temperature to 115°C;

[0049] 2. Add 2700kg of ethylene oxide, 237.96kg of propylene oxide and 6kg of dimethylamine, control the pressure of the reactor to 0.4MPa, and polymerize at a temperature of 110°C, and the reaction time is 3h;

[0050] 3. Reduce the pressure and degas for 1 hour to prepare polyether polyol which assists in improving the tearing and compression set properties of polyurethane;

[0051] It has been determined that the polyether polyol that helps improve the tearing and compression set properties of polyurethane has a hydroxyl value of 33.6 mgKOH / g, a viscosity of 1300 mPa·s / 25°C, a molecular weight of 5000, and a water content of 0.05%.

[0052] 1.2 A common...

Embodiment 2

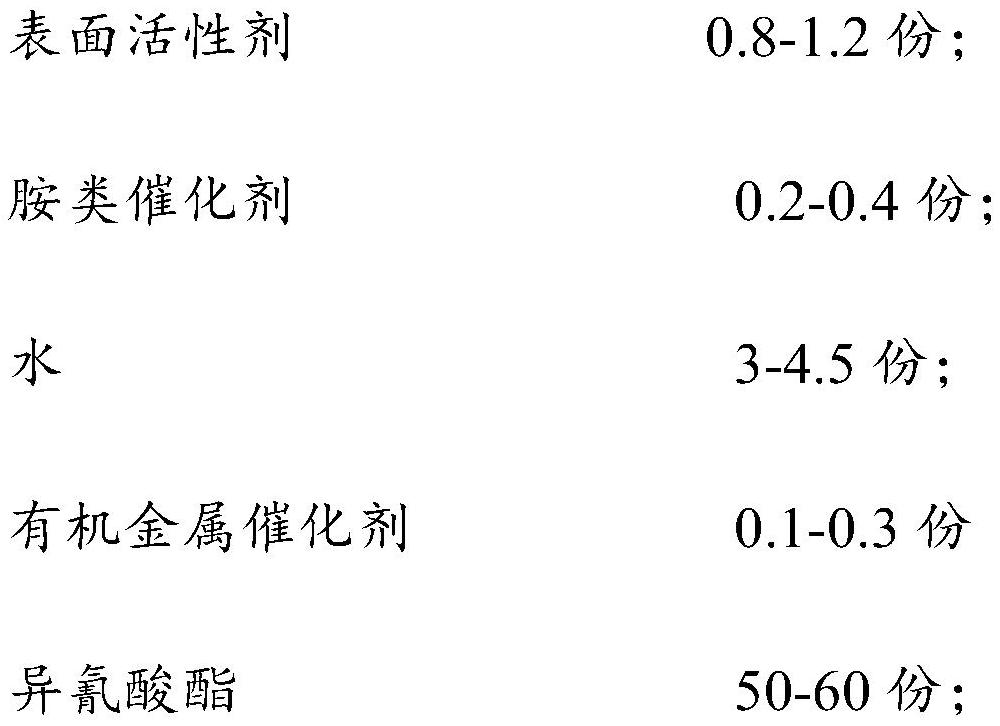

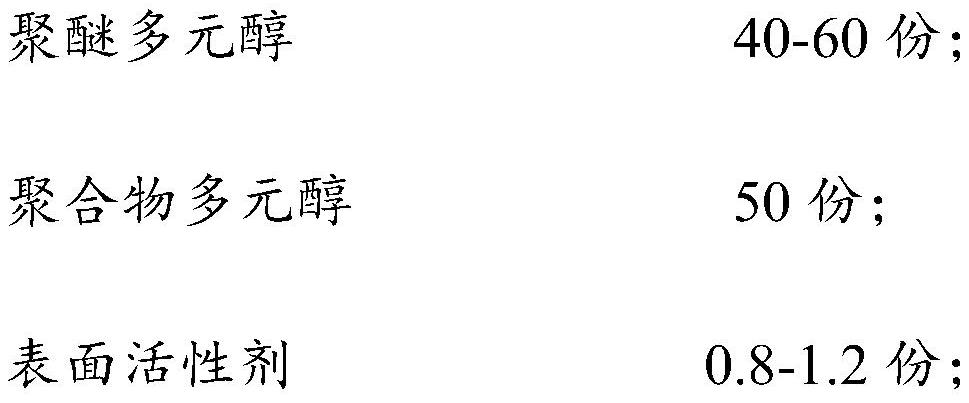

[0059] A kind of polyurethane common flexible foam, its raw material comprises:

[0060] The polyether polyol Puranol F 3500 of 40g, the polyether polyol of 10g embodiment 1 (the polyether polyol that assists to improve polyurethane tearing and compression set performance), the polymer polyol Puranol PP 2045B of 50g, 1.2g organic Silicon surfactant L580, 0.2g of amine catalyst A33, 0.15g of organotin catalyst D20, 3.9g of deionized water and 50.62g of toluene diisocyanate T80; the index is 115.

[0061] The preparation method of above-mentioned polyurethane common soft foam, comprises the steps:

[0062] (1) the polyether polyol Puranol F 3500, the polyether polyol of embodiment 1, polymer polyol, organosilicon surfactant, amine catalyst, organotin catalyst and deionized water are accurate by the weight in the formula Weigh and stir at 2000r / min for 1min to obtain component A. Preheat component A to 23°C for later use;

[0063] (2) Weigh toluene diisocyanate T80 according to...

Embodiment 3

[0066] A kind of polyurethane common flexible foam, its raw material comprises:

[0067] The polyether polyol Puranol F 3500 of 35g, the polyether polyol of 15g embodiment 1 (the polyether polyol that assists to improve polyurethane tearing and compression set performance), the polymer polyol Puranol PP 2045B of 50g, 1.2g organic Silicon surfactant L580, 0.2g amine catalyst A33, 0.12g organotin catalyst D20, 3.9g deionized water and 50.5g toluene diisocyanate T80; the index is 115.

[0068] The preparation method of above-mentioned polyurethane common soft foam, comprises the steps:

[0069] (1) the polyether polyol Puranol F 3500, the polyether polyol of embodiment 1, polymer polyol, organosilicon surfactant, amine catalyst, organotin catalyst and deionized water are accurate by the weight in the formula Weigh and stir at 2000r / min for 1min to obtain component A. Preheat component A to 23°C for later use;

[0070] (2) Weigh toluene diisocyanate T80 according to the weight i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com