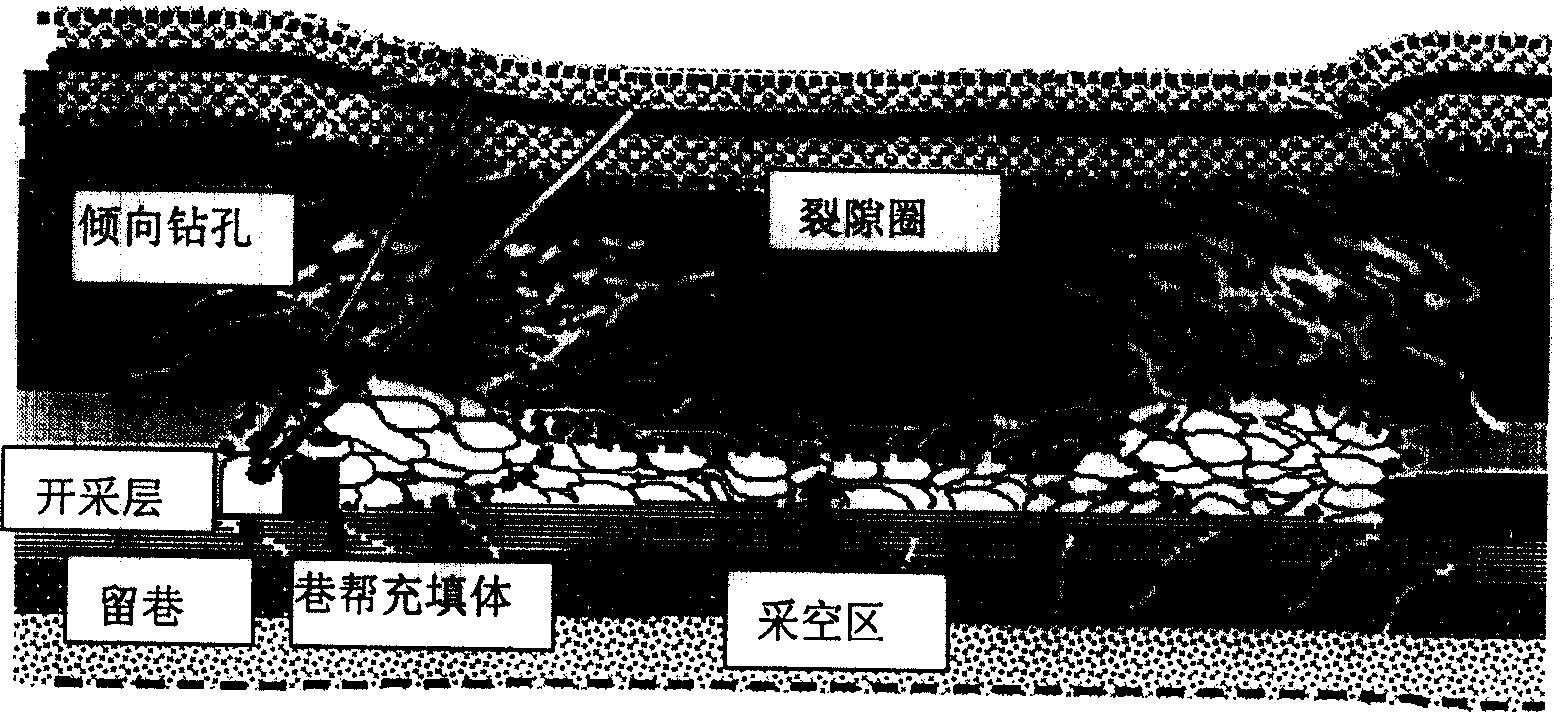

Side filling material of road retained for next sublevel

A filling material and cement technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of uneven roof subsidence, poor roadway maintenance, broken old roof, etc., and achieve good compression deformation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Preparation

[0031] Cement, fly ash, gravel, sand and water, the amount of each component is by weight:

[0032] 14 parts of cement and 20 parts of fly ash

[0033] 28 parts of stone, 22 parts of sand, 16 parts of water

[0034] The content of the effective components of the composite admixture is 1.3% of the total amount of cement and fly ash by weight percentage.

[0035] The composition of used composite admixture is by weight:

[0036] 30 parts of polycarboxylic acid as water reducing agent,

[0037] Carboxymethylcellulose as a water-retaining agent is 1.5 parts,

[0038] Rosin thermopolymer as air-entraining agent is 1.2 parts,

[0039] Calcium chloride as an early strength agent is 67.3 parts.

[0040] The cement, fly ash, gravel and sand used are:

[0041] Cement: P.042.5 grade, fly ash: II grade, stone: maximum particle size: 6mm, sand: medium sand

[0042] 2. Construction process

[0043] Cement, fly ash, gravel, sand and compound admixtures are mi...

Embodiment 2

[0049] 1. Ingredients

[0050] Cement, fly ash, gravel, sand and water, the amount of each component is by weight:

[0051] 20 parts of cement and 7 parts of fly ash

[0052] 40 parts of gravel, 20 parts of sand, 13 parts of water

[0053] The active ingredient content of the composite admixture is 1.6% by weight of the total amount of cement and fly ash.

[0054] The composition of used composite admixture is by weight percentage:

[0055] 30 parts of polycarboxylic acid as water reducing agent,

[0056] Carboxymethylcellulose as a water-retaining agent is 1.5 parts,

[0057] Rosin thermopolymer as air-entraining agent is 1.2 parts,

[0058] Calcium chloride as an early strength agent is 67.3 parts.

[0059] The cement, fly ash, gravel and sand used are:

[0060] Cement: P.042.5 grade, fly ash: II grade, stone: maximum particle size: 6mm, sand: medium sand

[0061] Two, construction process is the same as embodiment 1

[0062] 3. Product performance:

[0063] 1. The...

Embodiment 3

[0067] 1. Preparation

[0068] Cement, fly ash, gravel, sand and water, the amount of each component is by weight:

[0069] 10 parts of cement and 40 parts of fly ash

[0070] 15 parts of stone, 15 parts of sand, 20 parts of water

[0071] The content of the effective components of the composite admixture is 1.5% of the total amount of cement and fly ash by weight percentage.

[0072] The composition of used composite admixture is by weight:

[0073] 30 parts of polycarboxylic acid as water reducing agent,

[0074] Carboxymethylcellulose as a water-retaining agent is 1.5 parts,

[0075] Rosin thermopolymer as air-entraining agent is 1.2 parts,

[0076] Calcium chloride as an early strength agent is 67.3 parts.

[0077] The cement, fly ash, gravel and sand used are:

[0078] Cement: P.042.5 grade, fly ash: II grade, stone: maximum particle size: 6mm, sand: medium sand

[0079] Two, construction process is the same as embodiment 1

[0080] 3. Product performance:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com