Waterproof oilproof temperature-resistant anti-aging cable material and preparation method thereof

An anti-aging cable, waterproof and oil-proof technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

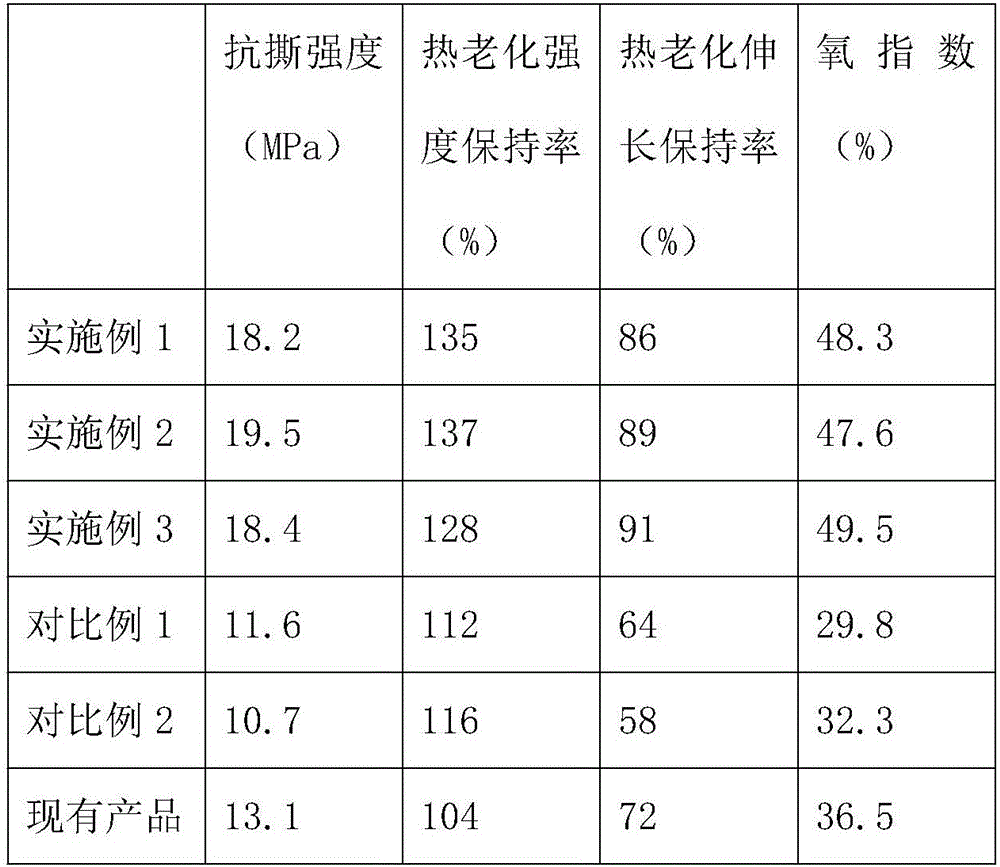

Examples

Embodiment 1

[0017] A waterproof, oil-proof, temperature-resistant and aging-resistant cable material, which is composed of the following raw materials in parts by weight: 30 parts of styrene-butadiene rubber, 25 parts of fluororubber, 2 parts of linear low-density polyethylene, 12 parts of fluorocarbon resin, and 2 parts of hydrogen-containing silicone oil , 5 parts of modified kaolin, 4 parts of carbon black, 5 parts of ammonium polyphosphate, 1 part of glass fiber, 3 parts of vermiculite, 2 parts of triethanolamine, 1 part of nickel, 2 parts of chromium, 3 parts of calcium carbonate, nano-silica 2 parts, ethylene glycol 4 parts, oxide powder 2 parts, sulfur 1 part, stabilizer 2 parts, plasticizer 3 parts, flame retardant 2 parts and fish oil 2 parts. The modified kaolin is mixed evenly with kaolin and potassium acetate, shaken for 3 minutes, ground for 105 minutes, left to stand for 12 hours, then dried at a constant temperature of 65 degrees Celsius for 24 hours, cooled to room temperat...

Embodiment 2

[0025] A waterproof, oil-proof, temperature-resistant and aging-resistant cable material, which is composed of the following raw materials in parts by weight: 36 parts of styrene-butadiene rubber, 32 parts of fluororubber, 4 parts of linear low-density polyethylene, 16 parts of fluorocarbon resin, and 4 parts of hydrogen-containing silicone oil , 7 parts of modified kaolin, 6 parts of carbon black, 8 parts of ammonium polyphosphate, 3 parts of glass fiber, 6 parts of vermiculite, 3 parts of triethanolamine, 2 parts of nickel, 3 parts of chromium, 5 parts of calcium carbonate, nano-silica 3 parts, ethylene glycol 6 parts, oxide powder 6 parts, sulfur 2 parts, stabilizer 4 parts, plasticizer 5 parts, flame retardant 4 parts and fish oil 6 parts. The oxide powder is a mixture of magnesium oxide and aluminum oxide powder.

[0026] The preparation method of the waterproof, oil-proof, temperature-resistant and aging-resistant, the specific steps are as follows:

[0027] Step 1, roa...

Embodiment 3

[0033] A waterproof, oil-proof, temperature-resistant and aging-resistant cable material, which is composed of the following raw materials in parts by weight: 42 parts of styrene-butadiene rubber, 35 parts of fluororubber, 6 parts of linear low-density polyethylene, 20 parts of fluorocarbon resin, and 5 parts of hydrogen-containing silicone oil , 8 parts of modified kaolin, 7 parts of carbon black, 10 parts of ammonium polyphosphate, 5 parts of glass fiber, 8 parts of vermiculite, 4 parts of triethanolamine, 3 parts of nickel, 4 parts of chromium, 7 parts of calcium carbonate, nano-silica 4 parts, ethylene glycol 8 parts, oxide powder 8 parts, sulfur 3 parts, stabilizer 6 parts, plasticizer 5 parts, flame retardant 6 parts and fish oil 7 parts. The modified kaolin is mixed evenly with kaolin and potassium acetate, shaken for 5 minutes, ground for 25 minutes, left to stand for 15 hours, then dried at a constant temperature of 75 degrees Celsius for 26 hours, cooled to room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com