Graphene-carbon nanometer tube film-based heat-conducting gasket and preparation method thereof

A carbon nanotube film and thermal pad technology, applied in the field of thermal conductive materials, can solve the problems of reduced tensile strength and compressibility, limitations, etc., and achieve the effects of improving interlayer strength, light weight, and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The present embodiment provides a method for preparing a graphene-carbon nanotube film-based thermal pad, the method comprising the following steps:

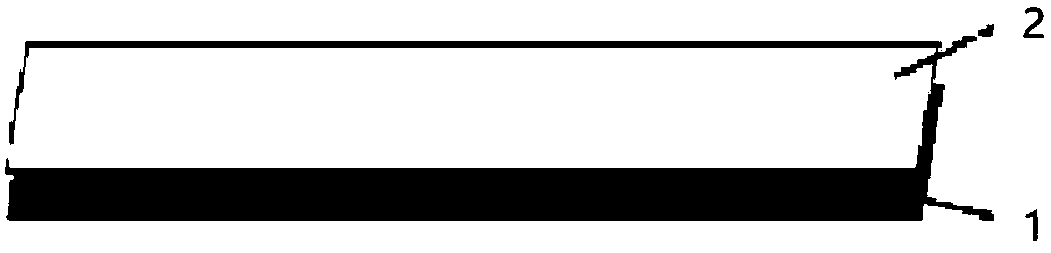

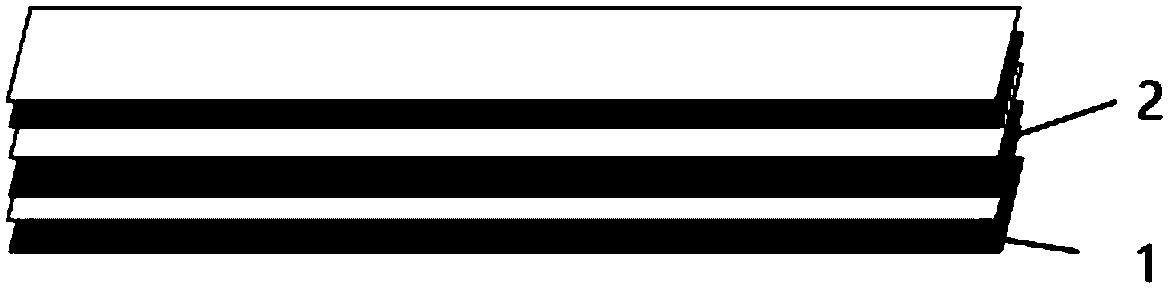

[0051] (1) Coating a thermally conductive adhesive on the surface of a single-layer graphene-carbon nanotube film with a thickness of 0.05 mm, the thickness of the thermally conductive adhesive is 100 μm, and superimposing 100 layers of the single-layer graphene-carbon nanotube film coated with thermally conductive adhesive , to obtain a composite graphene-carbon nanotube film;

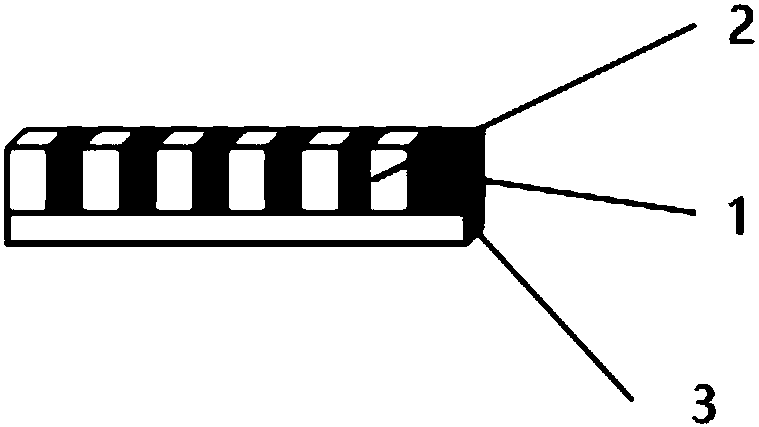

[0052] (2) The composite graphene-carbon nanotube film obtained in step (1) was cured at 80° C. and 0.1 MPa for 2 hours, and after curing, the composite graphene-carbon nanotube film was sliced radially and combined with a 10 μm thick thermal conductive base The material is composited to obtain a graphene-carbon nanotube film-based thermal pad.

[0053] When step (2) slices the thickness along the radial direction to 0.5mm, the thermal conduct...

Embodiment 2

[0055] The present embodiment provides a method for preparing a graphene-carbon nanotube film-based thermal pad, the method comprising the following steps:

[0056] (1) Coating a thermally conductive adhesive on the surface of a single-layer graphene-carbon nanotube film with a thickness of 2.0 mm, the thickness of the thermally conductive adhesive is 10 μm, and superimposing 2000 layers of the single-layer graphene-carbon nanotube film coated with thermally conductive adhesive , to obtain a composite graphene-carbon nanotube film;

[0057] (2) The composite graphene-carbon nanotube film obtained in step (1) was cured at 130° C. and 0.01 MPa for 0.5 h. After curing, the composite graphene-carbon nanotube film was sliced radially and combined with a 30 μm thick heat-conducting The substrate is composited to obtain a graphene-carbon nanotube film-based thermal pad.

[0058] When step (2) slices the thickness along the radial direction to 0.5mm, the thermal conductivity of the...

Embodiment 3

[0060] The present embodiment provides a method for preparing a graphene-carbon nanotube film-based thermal pad, the method comprising the following steps:

[0061] Immerse the carbon nanotube aggregates in the graphene dispersion for 40s, stretch the carbon nanotube aggregates in the radial direction, the stretching rate is 10%, and dry at 80°C for 5min to obtain a 1.0mm thick single-layer graphene- Carbon nanotube film;

[0062] (1) Coating thermally conductive adhesive on the surface of the obtained single-layer graphene-carbon nanotube film, the thickness of the thermally conductive adhesive is 30 μm, and superimposing 1000 layers of the single-layer graphene-carbon nanotube film coated with thermally conductive adhesive to obtain Composite graphene-carbon nanotube film;

[0063] (2) The composite graphene-carbon nanotube film obtained in step (1) was cured at 100° C. and 0.5 MPa for 1 h. After curing, the composite graphene-carbon nanotube film was sliced radially and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com