Cold-resisting oil-resisting modified fluorine rubber cable sheath material

A technology for modifying fluororubber and cable sheath, which is applied to rubber insulators and organic insulators, and can solve the problems of poor cold resistance of fluororubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

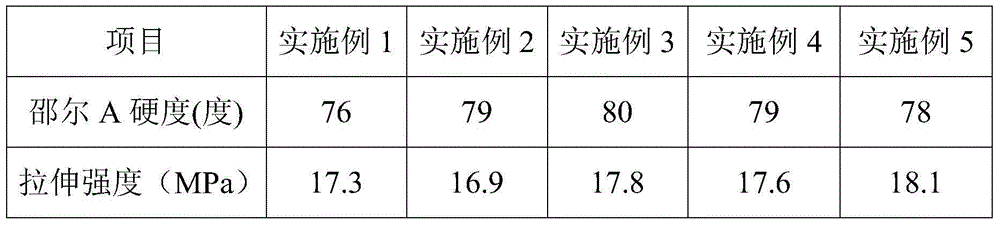

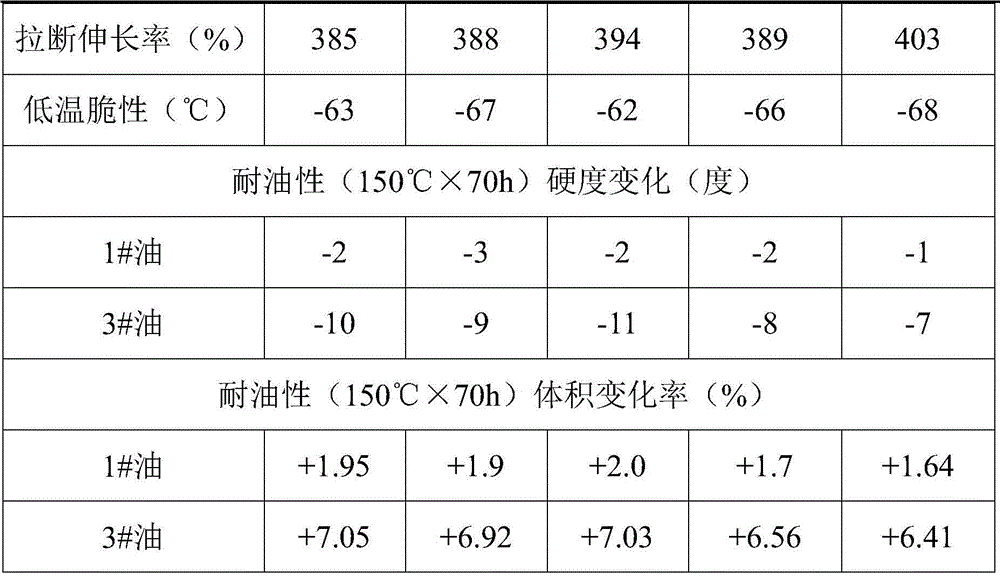

Examples

Embodiment 1

[0015] The cold- and oil-resistant modified fluororubber cable sheath material of the present invention includes the following components in parts by weight: 50 parts of fluoro rubber, 30 parts of silicone rubber, 20 parts of fluorosilicone rubber, 10 parts of pre-expanded organic clay, and 25 parts of silica Parts, 5 parts of ternary nylon, 2.5 parts of stearic acid, 3 parts of active magnesium oxide, 9 parts of rare earth complexes, 5 parts of calcium hydroxide, 0.5 parts of polyethylene glycol, 1 part of epoxy octyl stearate, epoxy 2.5 parts of triglyceride, 4 parts of bisphenol vulcanizing agent, 3 parts of accelerator, 0.5 parts of antioxidant MB, 1.5 parts of antioxidant 4010NA.

Embodiment 2

[0017] The cold- and oil-resistant modified fluororubber cable sheath material of the present invention includes the following components in parts by weight: 70 parts of fluororubber, 15 parts of silicone rubber, 15 parts of fluorosilicone rubber, 25 parts of pre-expanded organoclay, 15 parts of white carbon black Parts, 13 parts of ternary nylon, 1 part of stearic acid, 10 parts of activated magnesium oxide, 3 parts of rare earth complexes, 12 parts of calcium hydroxide, 1.8 parts of polyethylene glycol, 5 parts of epoxy octyl stearate, epoxy 1 part of triglyceride, 8 parts of bisphenol vulcanizing agent, 1 part of accelerator, 2 parts of antioxidant MB, 0.8 part of antioxidant 4010NA;

[0018] Wherein, the rare earth complex is 8-hydroxyisoquinoline rare earth complex; the pre-swelling agent of the pre-expanded organoclay is acrylic acid; and the polyethylene glycol is polyethylene glycol 300.

Embodiment 3

[0020] The cold- and oil-resistant modified fluororubber cable sheath material of the present invention includes the following components in parts by weight: 57 parts of fluoro rubber, 27 parts of silicone rubber, 16 parts of fluorosilicone rubber, 19 parts of pre-expanded organic clay, 17 parts of silica Parts, ternary nylon 10.3 parts, stearic acid 1.7 parts, active magnesium oxide 4.5 parts, rare earth complex 6 parts, calcium hydroxide 10 parts, polyethylene glycol 0.6 parts, epoxy octyl stearate 1.3 parts, epoxy 2.4 parts of triglyceride, 5 parts of bisphenol vulcanizing agent, 2.6 parts of accelerator, 1.7 parts of antioxidant MB, 1.3 parts of antioxidant 4010NA;

[0021] Wherein, the rare earth complex is a combination of a nicotinic acid rare earth complex and a 4-hydroxypyridine rare earth complex in any ratio; the pre-expanding agent of the pre-expanded organoclay is isoamyl alcohol, n-butanol, polyethylene glycol Combinations in any ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com