Production process of high-heat-conductivity flexible graphene film gasket

A technology of graphene film and flexible graphite, which is applied in the direction of graphene, modification through conduction and heat transfer, manufacturing tools, etc., can solve the problems of limitation, decrease in tensile strength and compressibility, etc., and achieve light weight and high tensile strength. Effect of large, excellent tensile and compression set properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

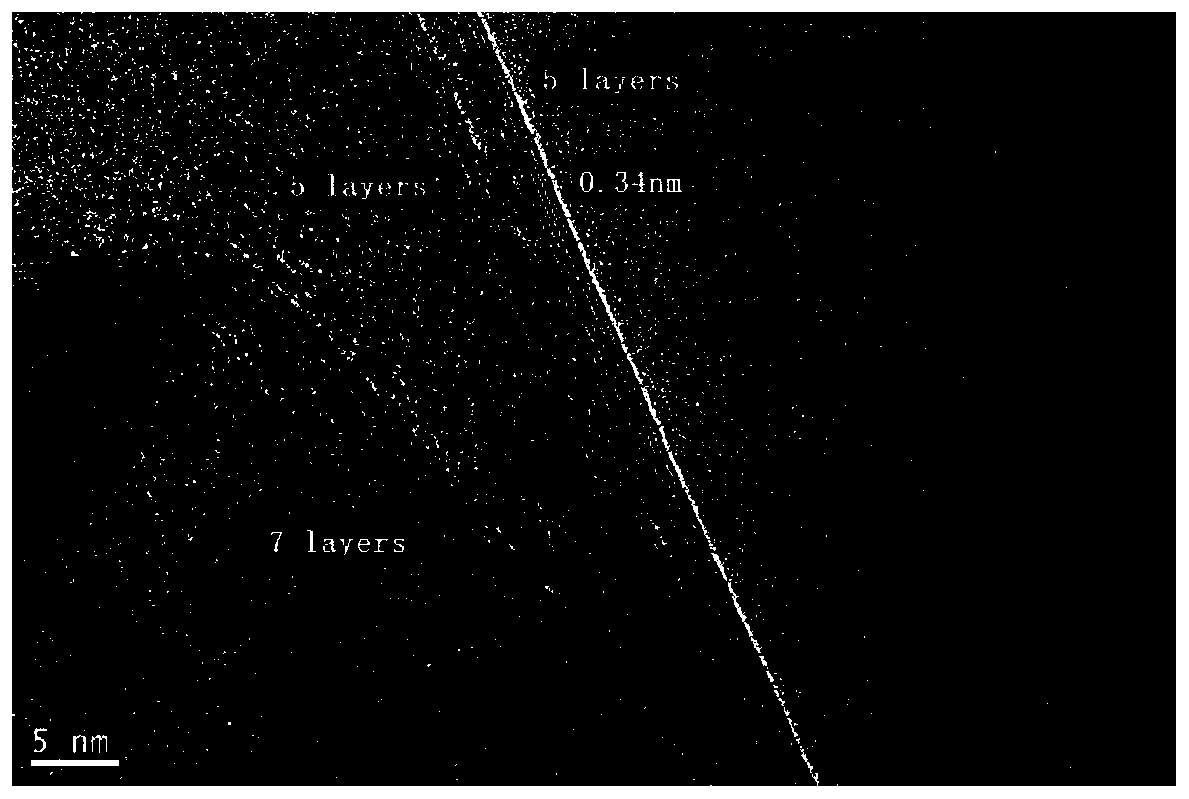

[0023] The invention provides a technical solution: a production process of a highly thermally conductive flexible graphene film gasket. The thermally conductive gasket includes a few-layer porous graphene film and a film-based heat-conducting network vertically arranged on a few-layer porous graphene film substrate. Including the following process steps:

[0024] 1), carry out mesh screening to graphene;

[0025] 2), the graphene through the mesh sieve is rolled into a graphene film by a roller press;

[0026] 3), preparing the flow coating slurry, and coating the flow coating slurry on the few-layer porous graphene film by a flow coating machine;

[0027] 4) After the slurry is coated on the few-layer porous graphene film, it is roll-formed and dried to form a vertically and horizontally intertwined film heat-conducting network perpendicular to the few-layer porous graphene film, thereby forming a composite high thermal conductivity flexible graphene Membrane gasket.

[0...

Embodiment 2

[0036] The invention provides a technical solution: a production process of a highly thermally conductive flexible graphene film gasket. The thermally conductive gasket includes a few-layer porous graphene film and a film-based heat-conducting network vertically arranged on a few-layer porous graphene film substrate. Including the following process steps:

[0037] 1), carry out mesh screening to graphene;

[0038] 2), the graphene through the mesh sieve is rolled into a graphene film by a roller press;

[0039]3), preparing the flow coating slurry, and coating the flow coating slurry on the few-layer porous graphene film by a flow coating machine;

[0040] 4) After the slurry is coated on the few-layer porous graphene film, it is roll-formed and dried to form a vertically and horizontally intertwined film heat-conducting network perpendicular to the few-layer porous graphene film, thereby forming a composite high thermal conductivity flexible graphene Membrane gasket.

[00...

Embodiment 3

[0049] The invention provides a technical solution: a production process of a highly thermally conductive flexible graphene film gasket. The thermally conductive gasket includes a few-layer porous graphene film and a film-based heat-conducting network vertically arranged on a few-layer porous graphene film substrate. Including the following process steps:

[0050] 1), carry out mesh screening to graphene;

[0051] 2), the graphene through the mesh sieve is rolled into a graphene film by a roller press;

[0052] 3), preparing the flow coating slurry, and coating the flow coating slurry on the few-layer porous graphene film by a flow coating machine;

[0053] 4) After the slurry is coated on the few-layer porous graphene film, it is roll-formed and dried to form a vertically and horizontally intertwined film heat-conducting network perpendicular to the few-layer porous graphene film, thereby forming a composite high thermal conductivity flexible graphene Membrane gasket.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com