Cable sheath rubber

A cable sheath and rubber technology, applied in the rubber field, can solve the problems of decreased elasticity and cold resistance, and achieve the effect of improving elasticity and cold resistance, excellent mechanical and physical properties, and achieving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

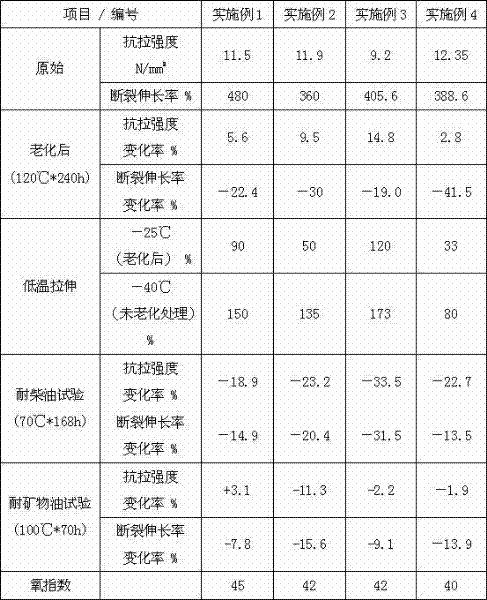

Examples

Embodiment 1

[0034] A cable jacket rubber made from:

[0035] Chlorinated polyethylene EXT1000 100 parts by weight;

[0036] 4 parts by weight of dicumyl peroxide;

[0037] 5 parts by weight of triallyl isocyanurate;

[0038] 1 weight part of antioxidant RD;

[0039] 15 parts by weight of decabromodiphenyl ether;

[0040] 5 parts by weight of antimony trioxide;

[0041] Carbon black N550 30 parts by weight;

[0042] 70 parts by weight of nano clay;

[0043] 15 parts by weight of high-activity magnesium oxide (activity coefficient is 15S);

[0044] Chlorinated paraffin oil (52#) 15 parts by weight;

[0045] Dioctyl sebacate 15 parts by weight;

[0046] Microcrystalline wax (60#) 8 parts by weight;

[0047] 5 parts by weight of lead stearate;

[0048] Silane coupling agent A-172 0.5 parts by weight.

[0049] The preparation method is as follows: weigh various raw materials according to the proportion, first heat the internal mixer to 70°C, add chlorinated polyethylene and masti...

Embodiment 2

[0051] A cable jacket rubber made from:

[0052] Chlorinated polyethylene EXT1000 100 parts by weight;

[0053] 6 parts by weight of dicumyl peroxide;

[0054] 6 parts by weight of triallyl isocyanurate;

[0055] 1.5 parts by weight of antioxidant RD;

[0056] 20 parts by weight of decabromodiphenyl ether;

[0057] 10 parts by weight of antimony trioxide;

[0058] 40 parts by weight of carbon black N550;

[0059] The preparation method is as follows: weigh various raw materials according to the proportion, first heat the internal mixer to 70°C, add chlorinated polyethylene and masticate for 3 minutes, then add other raw materials and knead for 5 minutes, and the screw speed is 40 rpm. After the internal mixer is blanked, it is passed through the open mixer for 5 times, and finally the open mixer blanking is completed.

Embodiment 3

[0061] A cable jacket rubber made from:

[0062] Chlorinated polyethylene EXT1000 100 parts by weight;

[0063] 2 parts by weight of dicumyl peroxide;

[0064] 3 parts by weight of triallyl isocyanurate;

[0065] 0.5 parts by weight of antioxidant RD;

[0066] 5 parts by weight of decabromodiphenyl ether;

[0067] 5 parts by weight of antimony trioxide;

[0068] 20 parts by weight of carbon black N550;

[0069] 40 parts by weight of nano clay;

[0070] 10 parts by weight of high-activity magnesium oxide (activity coefficient is 15S);

[0071] Chlorinated paraffin oil (52#) 10 parts by weight;

[0072] Dioctyl sebacate 10 parts by weight;

[0073] Microcrystalline wax (60#) 5 parts by weight;

[0074] 3 parts by weight of lead stearate;

[0075] Silane coupling agent A-172 0.5 parts by weight.

[0076] The preparation method is as follows: weigh various raw materials according to the proportion, first heat the internal mixer to 70°C, add chlorinated polyethylene a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com