Low-compression permanent-deformation carboxylic acid type acrylate rubber, and preparation method thereof

An acrylate, permanent deformation technology, applied in the field of synthetic rubber compounding and processing, can solve the problems of increasing the hardness and tensile strength of the rubber compound, cannot reduce the compression set of the rubber compound, and the effect of the compression set is not obvious. Coupling strength, improving compression set performance, and the effect of good compressive capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A preparation method of low compression set carboxylic acid type acrylate rubber, comprising the following steps:

[0034] Carboxylic acid type acrylate rubber, fast extruded carbon black, precipitated white carbon black, processing aid and anti-aging agent are added into an open mill for the first mixing to obtain the first mixed rubber. The specific steps of mixing for the first time in the embodiment of the present invention are: (1) weighing carboxylic acid type acrylate rubber, fast extruded carbon black, precipitated white carbon black, processing aid and anti-aging agent according to the proportion; (2) ) Open the mill, press the stearic acid on the roller, then put the carboxylic acid type acrylate rubber into the roller, make the rubber cover the roller, adjust the roller distance, and keep a small amount of glue on the roller; (3) put Quickly extrude carbon black, precipitated silica, and anti-aging agent and evenly add them to the roller for mixing. When add...

Embodiment 1

[0039] A preparation method of low compression set carboxylic acid type acrylate rubber, comprising the following steps:

[0040] (1) Weigh the following raw materials by weight: acrylate rubber ACM-120: 100 parts; fast extrusion carbon black N-550: 25 parts; precipitated white carbon black: 25 parts; silane coupling agent Si-69: 2 anti-aging agent TK-100: 5 parts; stearic acid: 2 parts; vulcanizing agent No. 1: 1 part; accelerator DOTG: 2 parts.

[0041] (2) Open the open mill, press stearic acid on the roller, then put carboxylic acid type acrylate rubber into the roller, make the rubber wrap the roller, adjust the roller distance, and keep a small amount of glue on the roller;

[0042] (3) Evenly add quick-extruded carbon black, precipitated white carbon black, and anti-aging agent into the roller for mixing. When adding half of the quick-extruded carbon black and precipitated white carbon black, perform 3 / 4 cutting knife 1 on each side 2 times, and then add the remaining ...

Embodiment 2

[0055] A preparation method of low compression set carboxylic acid type acrylate rubber, comprising the following steps:

[0056] (1) Weigh the following raw materials by weight: acrylate rubber ACM-220: 100 parts; fast extrusion carbon black N-550: 25 parts; precipitated white carbon black 25 parts, silane coupling agent Si-69: 2 parts ; Antiaging agent TK-100: 5 parts; Stearic acid: 2 parts; No. 1 vulcanizing agent 1 part; Accelerator DOTG 2 parts;

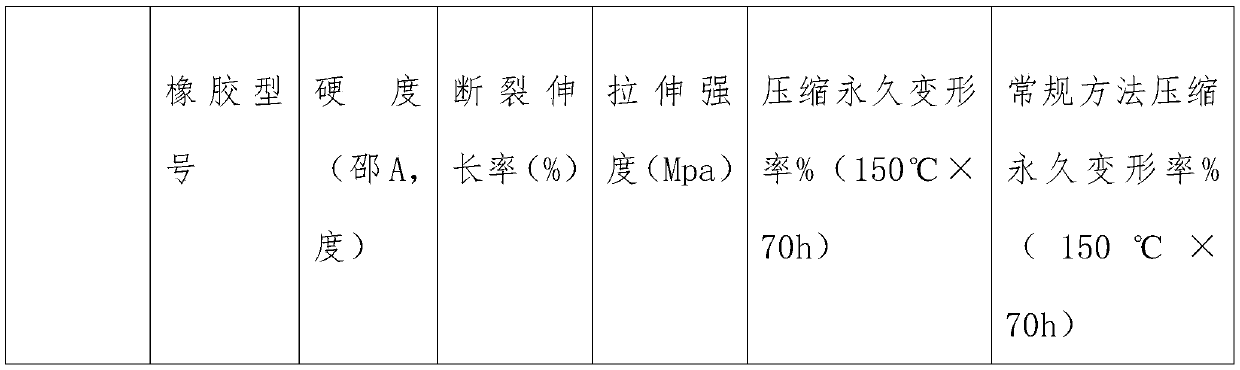

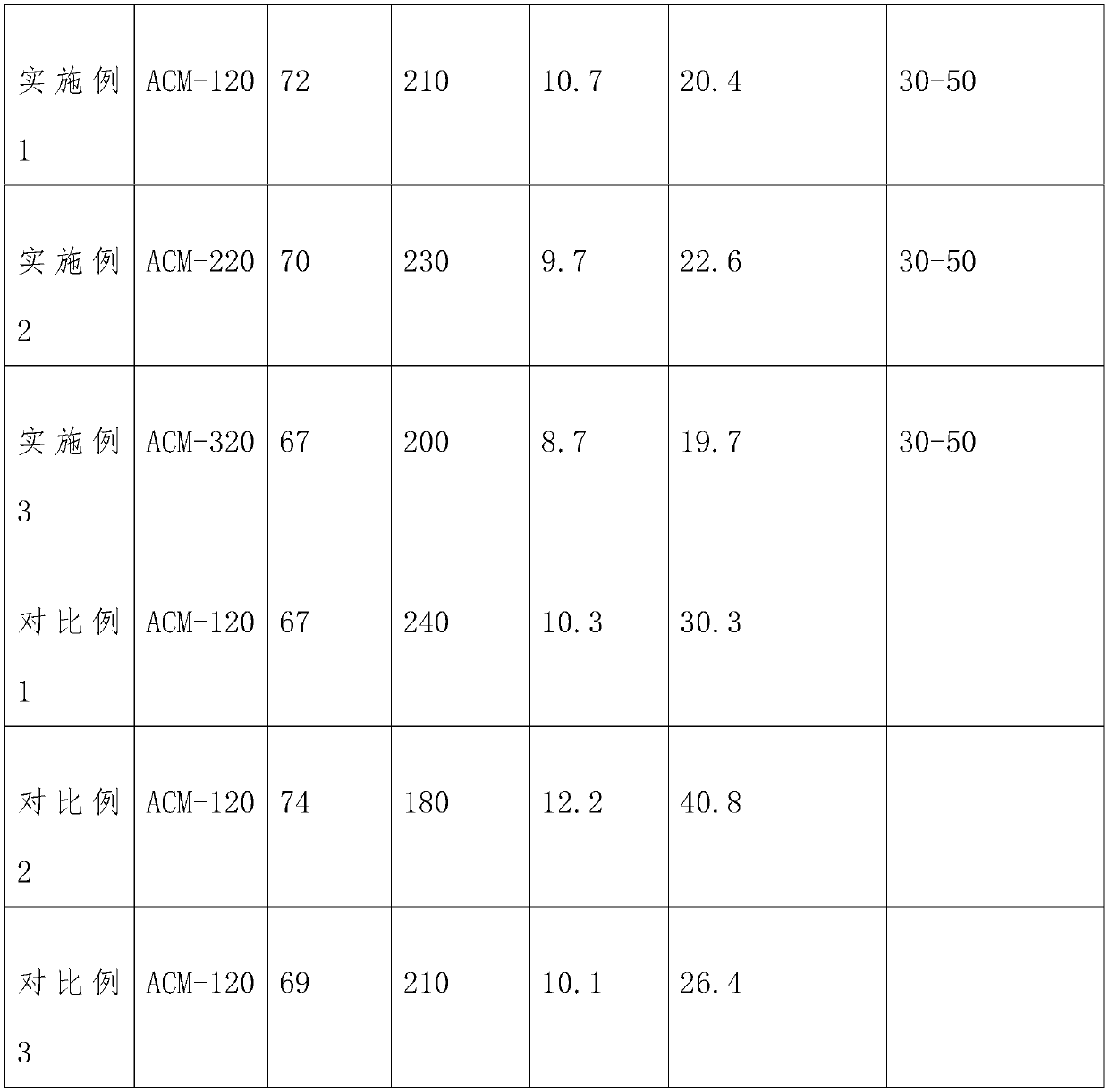

[0057] The processing and detection method are the same as in Example 1, and the detection results are as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com