Vibration-damping rubber composition

A rubber composition and anti-vibration technology, which can be applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as the reduction of physical properties, achieve excellent vibration resistance and fatigue resistance, excellent thermal aging resistance, and take into account spring characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Mix 100 parts of NR, 5 parts of zinc oxide, 1 part of stearic acid, 1 part of anti-aging agent, 2 parts of wax, 3 parts of oil, 30 parts of carbon black, 0.1 part of vulcanization aid (i), and use them in Banbury The mixer performs kneading at 140°C for 5 minutes. Next, 1 part of a vulcanizing agent, 2 parts of a vulcanization accelerator (i), and 1 part of a vulcanization accelerator (ii) were mixed therein, and kneaded at 60°C for 5 minutes using an open mill to prepare a vibration-proof rubber composition.

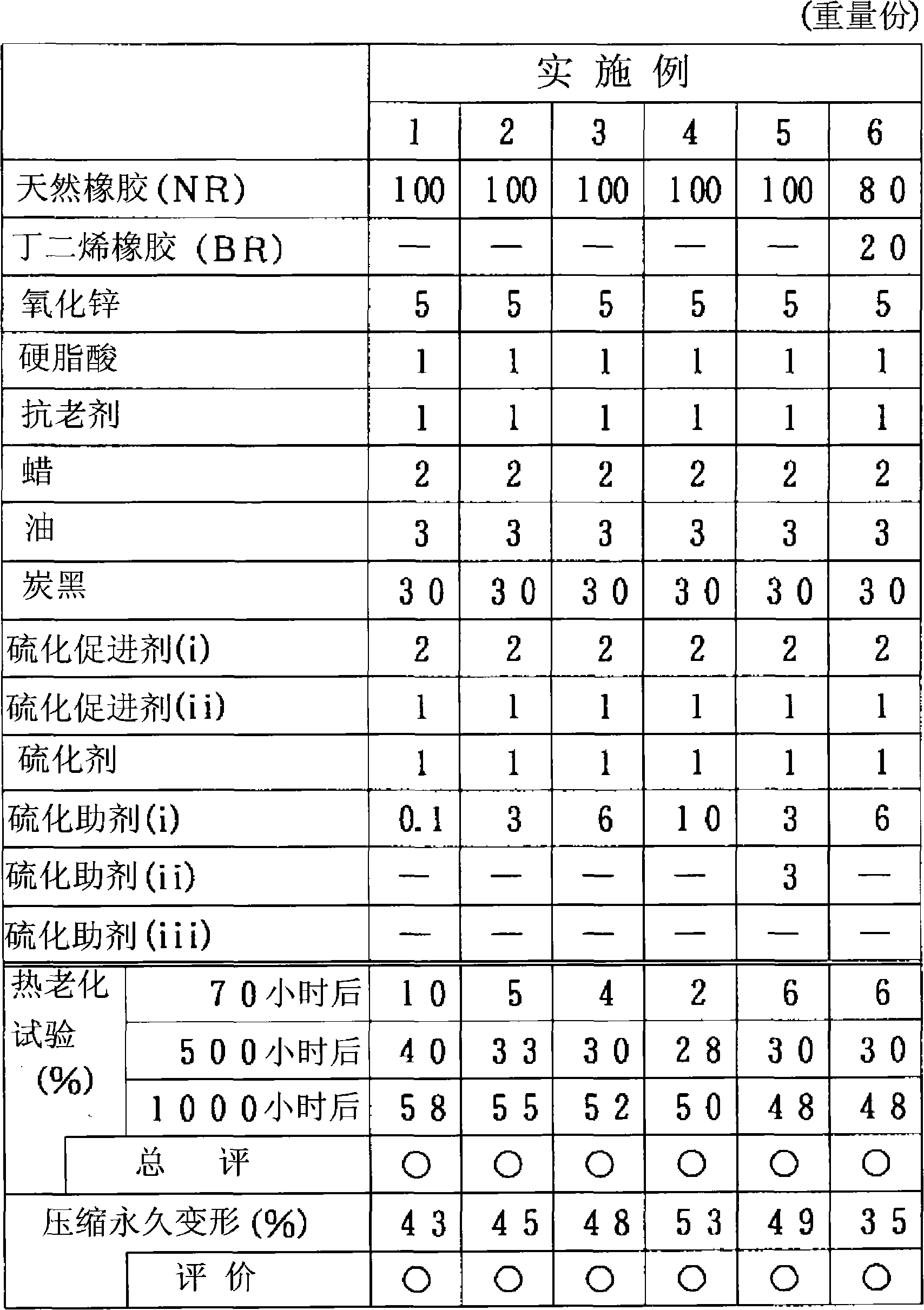

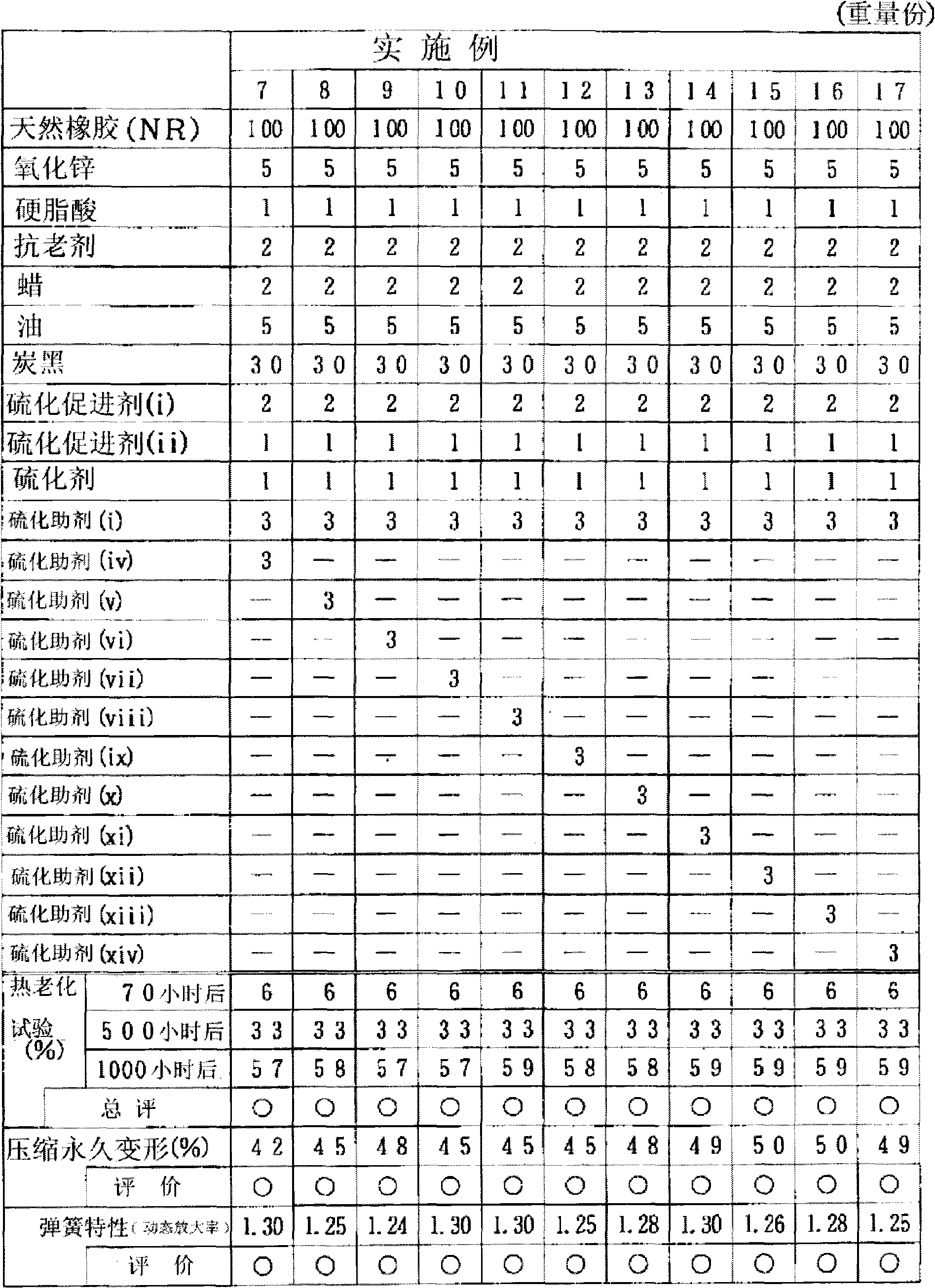

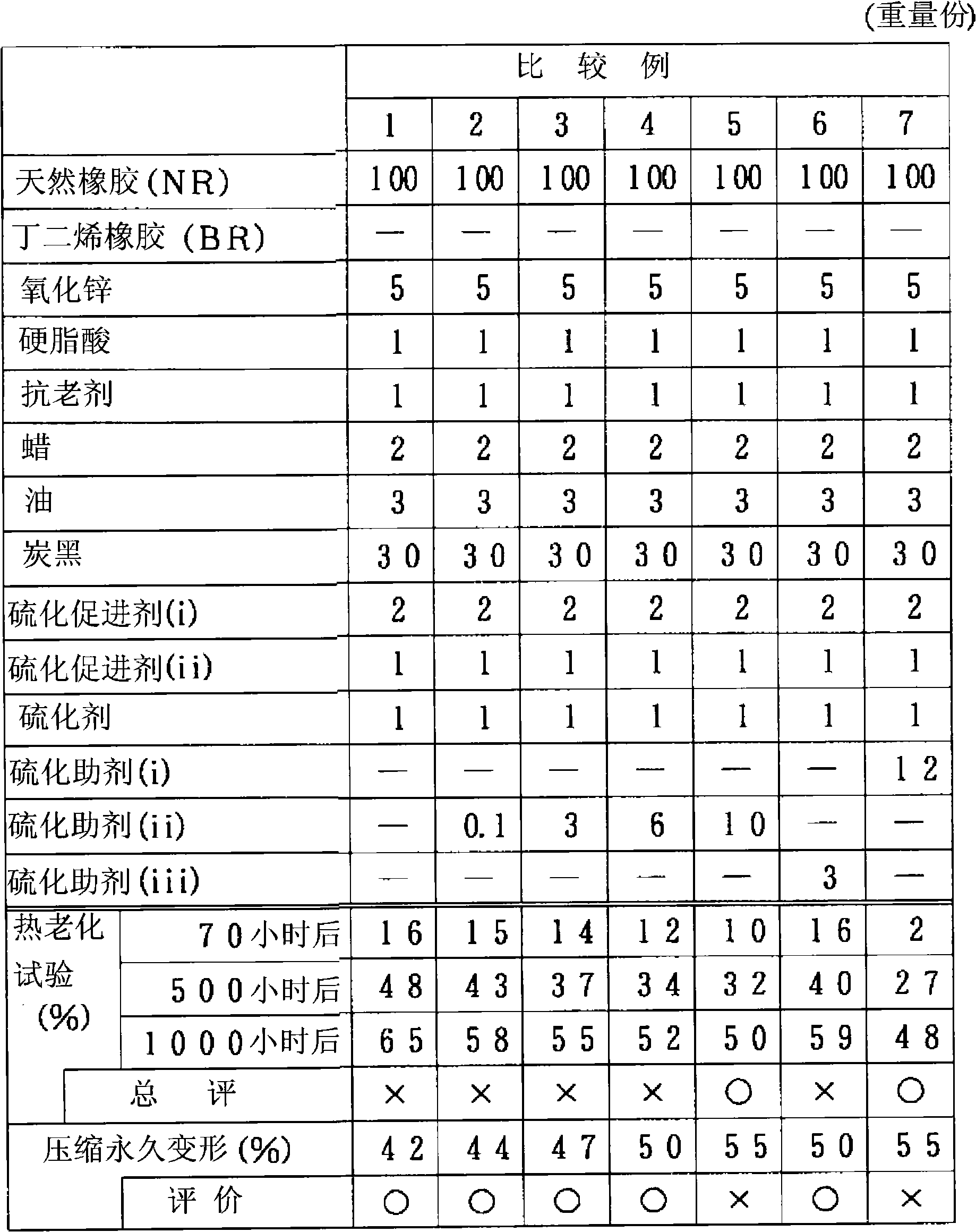

Embodiment 2~17、 comparative example 1~7

[0097] As shown in Tables 1 to 3 described later, a vibration-proof rubber composition was prepared based on Example 1, except that the compounding amount of each component was changed.

[0098] Using the anti-vibration rubber compositions of the examples and comparative examples obtained in this way, each characteristic was evaluated according to the following criteria (in addition, the evaluation of spring characteristics was carried out only in Examples 7 to 17). The results are shown in Table 1 to Table 3 described later.

[0099] 〔Heat aging experiment〕

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com