Neoprene vibration reduction gasket material

A neoprene rubber and vibration damping pad technology, applied in the field of rubber materials, can solve the problems of weather resistance, user inconvenience, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

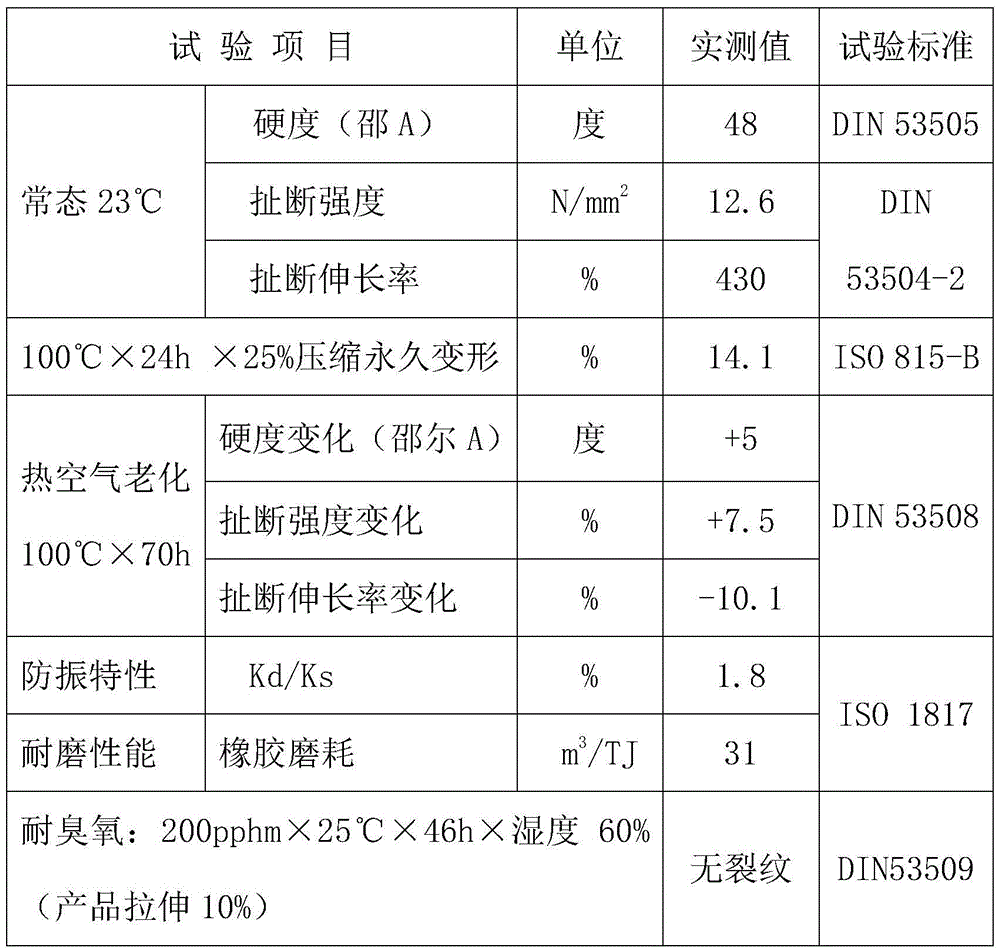

Examples

Embodiment 1

[0020] A neoprene vibration damping gasket material, the raw materials of which by weight include: 55 parts of neoprene, 35 parts of natural rubber, 30 parts of butyl rubber, carbon black N3303 parts, carbon black N6603 parts, organically modified rector 20 parts of stone, 4 parts of light calcium, 8 parts of nano zinc oxide, 1 part of aluminum hydroxide, 6 parts of red phosphorus masterbatch, silane coupling agent KH5702 parts, barium stearate 0.3 parts, accelerator DM 1.5 parts, promote 3 parts of TMTM, 0.1 part of sulfur, 0.3 part of anti-aging agent, 0.1 part of anti-aging auxiliary, 8 parts of trioctyl trimellitate, 3 parts of tributyl citrate, 6 parts of epoxy soy butyl oleate;

[0021] The chloroprene rubber is a copolymer prepared by emulsion copolymerization of 100 parts by weight of chloroprene and 2 parts by weight of vinyl chloride; the organically modified rectorite is a sawdust cellulose quaternary ammonium salt modified rectorite, The preparation method includes: a...

Embodiment 2

[0024] A neoprene vibration damping gasket material, the raw materials of which by weight include: 75 parts of neoprene, 25 parts of natural rubber, 45 parts of butyl rubber, carbon black N3301 parts, carbon black N6606 parts, organically modified rector Stone 12 parts, light calcium 10 parts, nano zinc oxide 3 parts, aluminum hydroxide 6 parts, red phosphorus masterbatch 3 parts, silane coupling agent KH5704 parts, barium stearate 0.1 parts, accelerator DM2.5 parts, promote 1 part of TMTM, 0.2 part of sulfur, 0.1 part of anti-aging agent, 0.3 part of anti-aging auxiliary, 5 parts of trioctyl trimellitate, 5 parts of tributyl citrate, 2 parts of epoxy soy butyl oleate;

[0025] The chloroprene rubber is a copolymer prepared by emulsion copolymerization of 100 parts by weight of chloroprene and 30 parts by weight of vinyl chloride; the organically modified rectorite is a sawdust cellulose quaternary ammonium salt modified rectorite, The preparation method includes: adding 15 parts...

Embodiment 3

[0028] A neoprene vibration damping gasket material, the raw materials of which by weight include: 60 parts of neoprene, 32 parts of natural rubber, 35 parts of butyl rubber, carbon black N3302 parts, carbon black N6604 parts, organically modified rector Stone 18 parts, light calcium 6 parts, nano zinc oxide 7 parts, aluminum hydroxide 3 parts, red phosphorus masterbatch 5 parts, silane coupling agent KH5703 parts, barium stearate 0.2 parts, accelerator DM 1.8 parts, promote 2 parts of TMTM, 0.1 part of sulfur, 0.2 part of anti-aging agent, 0.1 part of anti-aging auxiliary, 7 parts of trioctyl trimellitate, 3 parts of tributyl citrate, 5 parts of epoxy soy butyl oleate;

[0029] The chloroprene rubber is a copolymer prepared by emulsion copolymerization of 100 parts by weight of chloroprene and 16 parts by weight of vinyl chloride; the organically modified rectorite is a sawdust cellulose quaternary ammonium salt modified rectorite, The preparation method includes: adding 12 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com