Main feed water isolating valve

A technology for isolating valves and main water supply, applied in sliding valves, valve details, valve devices, etc., to achieve the effects of compact structure, reduced possibility of failure, and improved seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

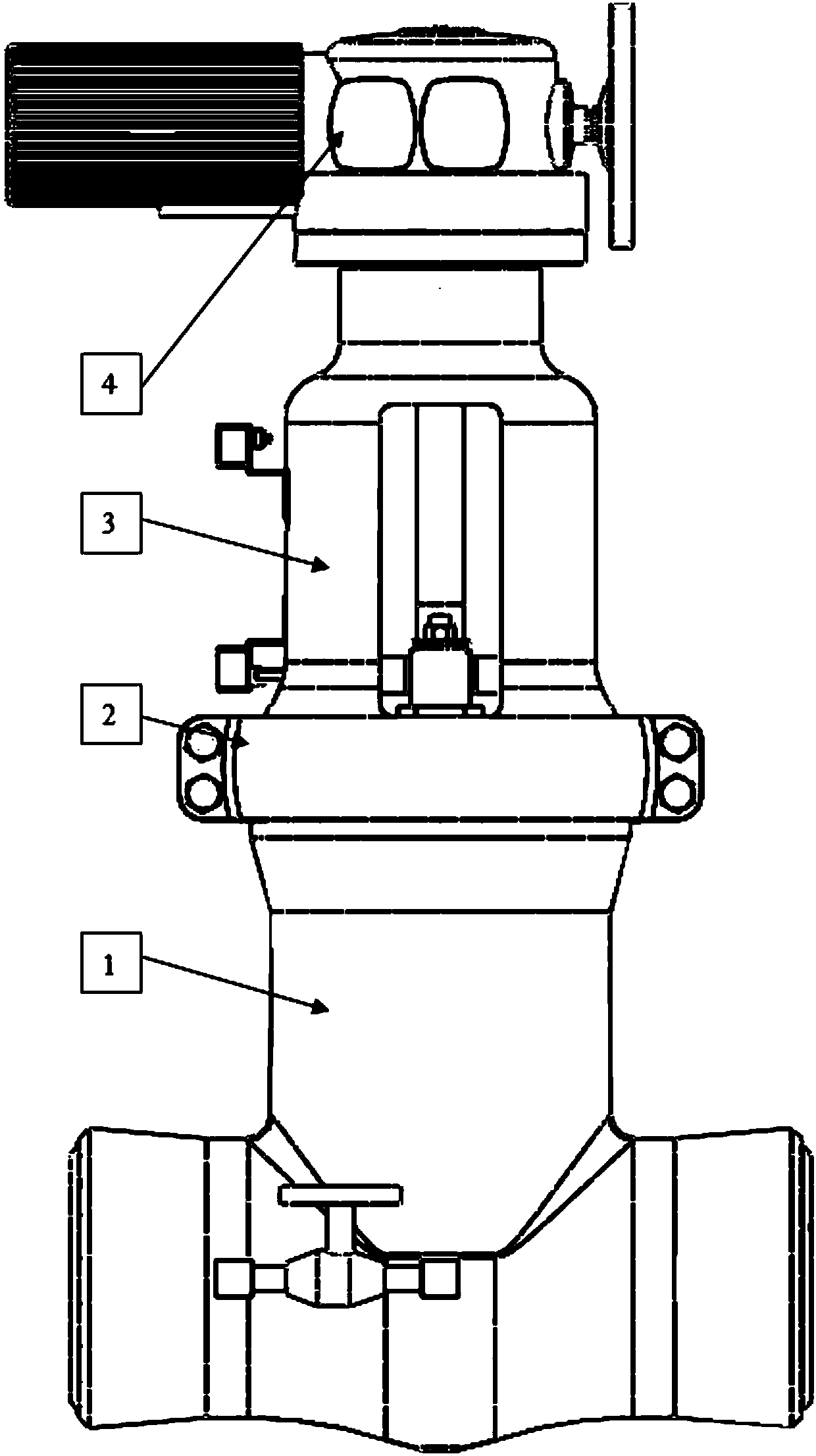

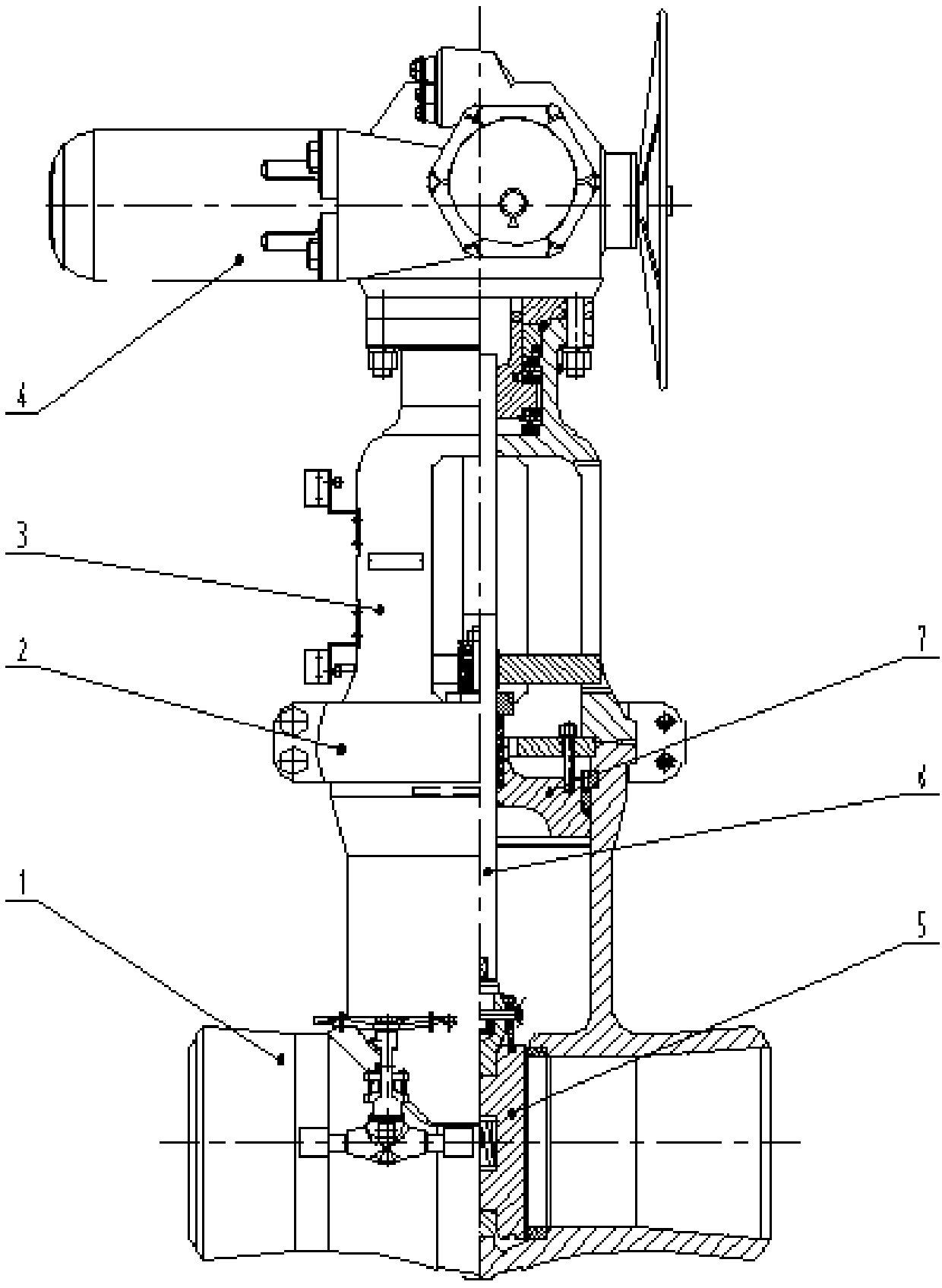

[0012] as attached figure 1 And attached figure 2 As shown, a main water supply isolation valve includes a valve body 1, a clamp 2, a bracket 3, and an electric device 4, wherein the valve body 1 is a "T"-shaped three-way structure, and the "T"-shaped straight-through pipeline is connected to the nuclear power plant The main pipeline is connected, and the right-angle passage is provided with a clamp 2, which is a tightenable ring structure. The clamp 2 is provided with a bracket 3. 3 corresponding to the groove, the clamp 2 is provided with a fastening bolt, through which the clamp 2 can be tightened, so that the valve body 1, the clamp 2 and the bracket 3 are fixedly connected, and the bracket 3 is a round-shaped part. An electric device 4 is arranged above the support 3 .

[0013] In the channel of the valve body 1, a gate 5, a valve stem 6 and a stuffing box 7 are sequentially arranged in the direction of the clamp 2, wherein the gate 5 is composed of two parallel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com