Method of producing protective tubes

一种防护管、阶段的技术,应用在制造防护管领域,能够解决没有扁平带到防护管成形过程描述等问题,达到生产成本低、好隔热和防振效果、好柔性和弹性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The weaving of some fabric strips by warping on a Raschel machine has the following characteristics:

[0047] Production: Liba (LIBA)

[0048] Model: RACOP-06

[0049] Number of knitting needles: 1

[0050] Width of knitting needles: 130″

[0051] Number of bars: 6 (3 of which form a mesh)

[0052] Specifications: 14 pins per inch

[0053] Speed: close to 600 lines of mesh per minute

[0054] This fabric type is standard and its workings and possibilities are known to anyone skilled in the art.

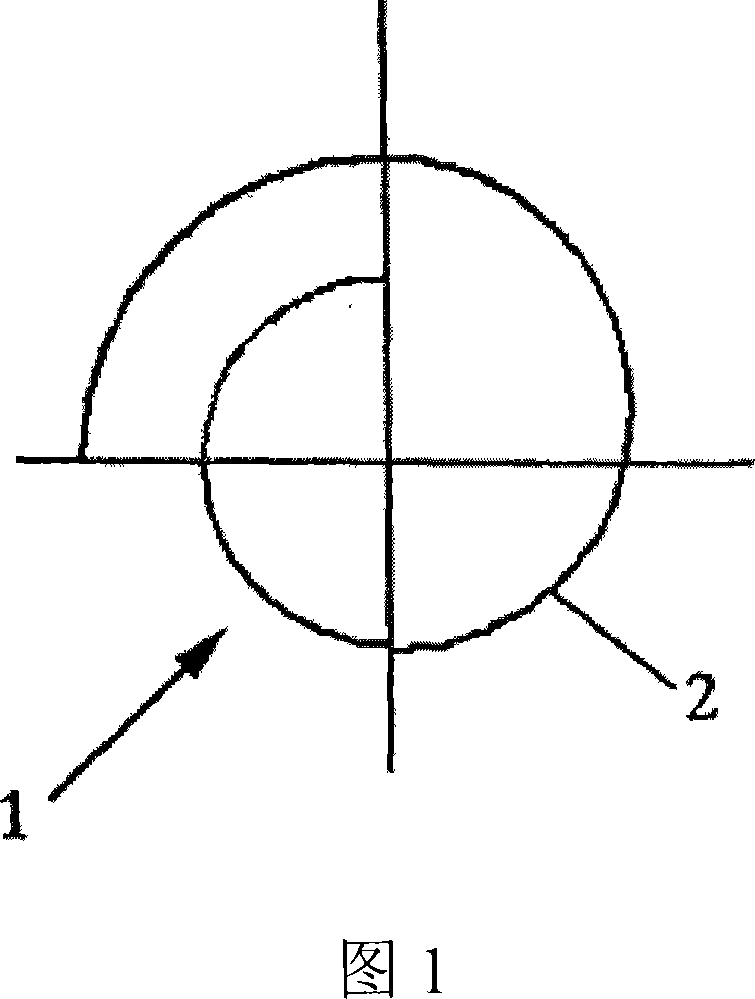

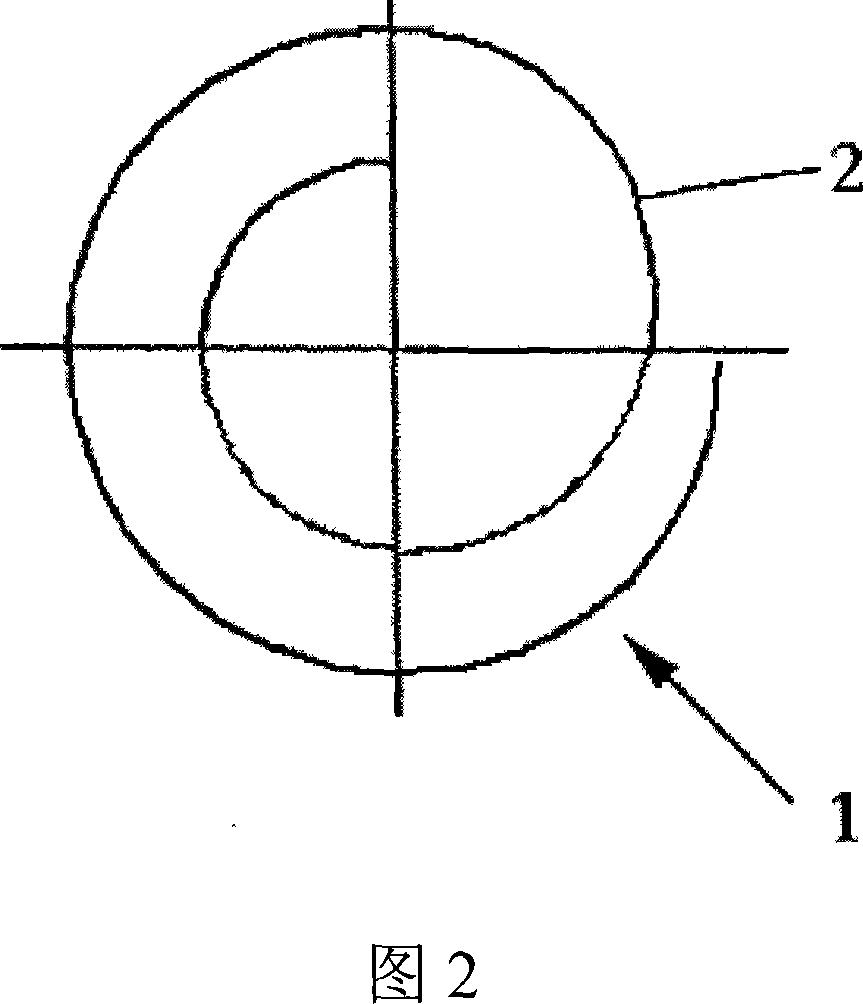

[0055] At the same time 25 types of fabric strips (indicated with reference numeral 2) having a width between 50-200 mm were obtained, which were characterized as follows.

[0056] - The specific process of the three-bar structure is as follows:

[0057] P-1:2-0 / 0-2 / / Connect with post-ring chain

[0058] P-2: 2-4 / 2-0 / / connect with knitted fabric

[0059] P-3: 0-0 / 8-8 / / Connect with the weft on the four pins

[0060] -Threading and material of bar:

[0061] P-1: full ...

Embodiment 2

[0076] In the second preferred embodiment, compared with the first preferred embodiment, the following changes are introduced:

[0077] The specific process of the four-bar structure is as follows:

[0078] P-1: 2-0 / 0-2 / 4-6 / 6-4 / connected with offset post ring chain

[0079] P-2: 4-6 / 6-4 / 2-0 / 0-2 / / Connect with offset post ring chain

[0080] P-3: 2-4 / 2-0 / / connect with weft

[0081] P-4:0-0 / 8-8 / / Connect with the weft on the four pins

[0082] Bar threading and material:

[0083] P-1: 1 full-1 empty; 0.22mm diameter polyester monofilament (PET), or 0.20mm diameter polyamide monofilament (PA)

[0084] P-2: 1 full-1 empty; 0.22mm diameter polyester monofilament (PET), or 0.20mm diameter polyamide monofilament (PA)

[0085] P-3: full wear; 500 dtex polyester (PET) multifilament

[0086] P-4: full thread; 0.22mm diameter high shrinkage polyester (PET) monofilament

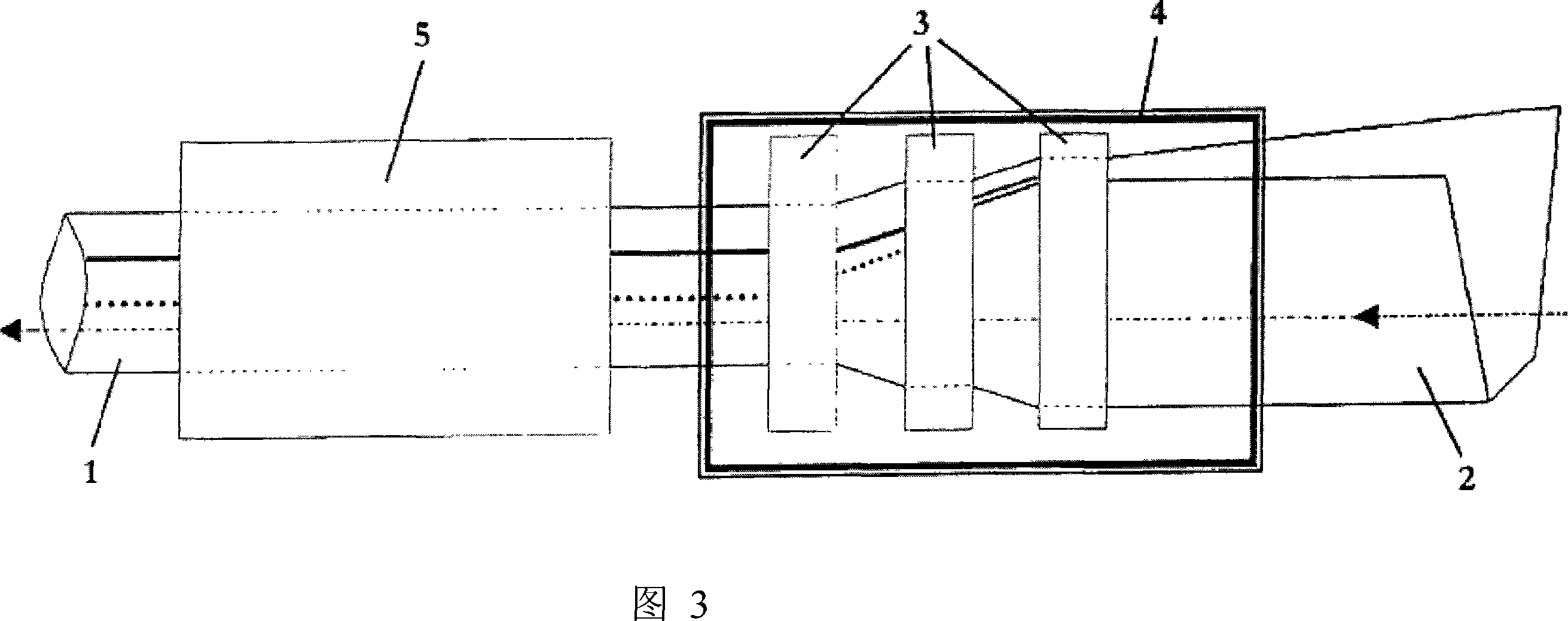

[0087] The strip obtained during weaving is then used to complete the forming phase, which is the same as describ...

Embodiment 3

[0093] In the third preferred embodiment, compared with the first preferred embodiment, the following changes are introduced:

[0094] The specific process of the two bar structure is as follows:

[0095] P-1: 2-0 / 0-2 / / link with offset post ring chain

[0096] P-2: 0-0 / 6-6 / / Connect with the weft on the three pins

[0097] Bar threading and material:

[0098] P-1: full thread; 68×2 tex (tex) glass fiber multifilament

[0099] P-2: full thread; 68×2 tex (tex) glass fiber multifilament

[0100] Unlike those belts obtained in the first and second examples, the belts obtained with such connection structures, materials and wefts are characterized by their resistance to high temperatures, the belts can support a temperature of 600°C 90 hours without losing more than 50% of its mechanical properties.

[0101] In the forming stage of this embodiment: with silicon copper or resin mixture, for example the acrylic acid PR resin impregnation belt that REPSOL company manufactures, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| base weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com