A kind of titanium alloy processing high-strength square milling insert

A milling blade, high-strength technology, applied in the direction of metal processing equipment, milling cutter, milling machine equipment, etc., can solve the problems of low processing efficiency, tool wear, and low processing surface quality, so as to achieve low processing cost, ease wear, improve The effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

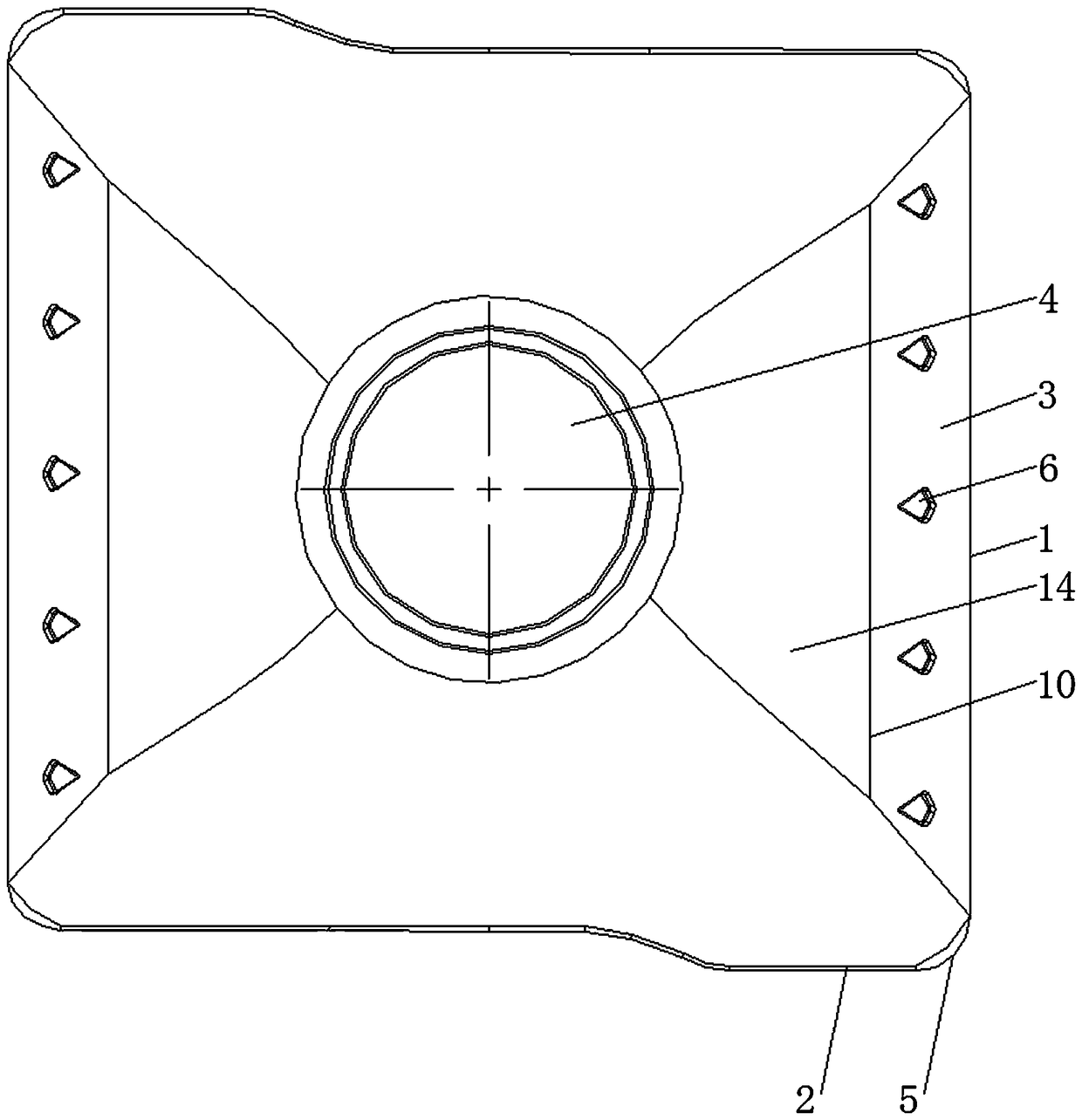

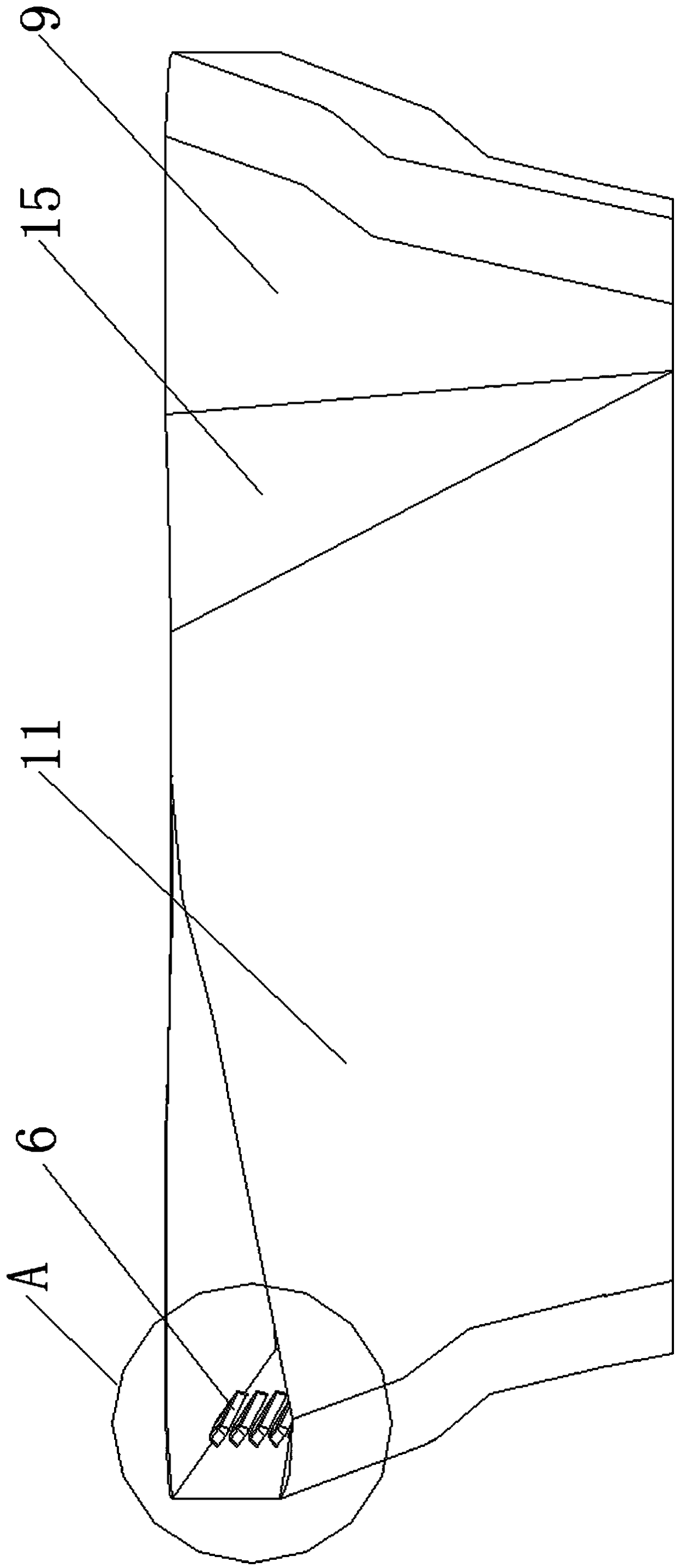

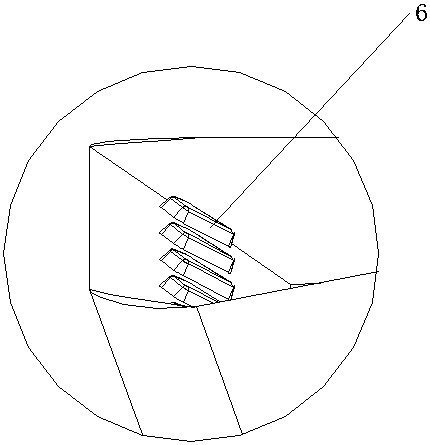

[0023] Specific implementation mode one: as Figure 1~Figure 5 As shown, a titanium alloy processing high-strength square milling insert, the milling insert is made of hard alloy material, the top surface area of the milling insert is greater than the area of the bottom surface 13, and the horizontal cross-sectional shape of the milling insert is a square (The side length of the milling blade is 10.2mm, and the thickness is 3.6mm). The geometric center of the milling blade is provided with a threaded mounting hole 4 for fixed connection with the cutter bar along the thickness direction; the milling blade is provided with two Tool tip 5, the two tool tips 5 are arranged symmetrically with respect to the geometric center of the milling insert (both tool tips 5 have a radius of 0.5mm); one side of each tool tip 5 is provided with a main cutting edge 1 , the other side of each tool nose 5 is provided with a wiper edge 2, the two main cutting edges 1 are arranged symmetrically ...

specific Embodiment approach 2

[0026] Specific implementation mode two: as Figure 1~Figure 3 and Figure 5 As shown, the high-strength square milling insert for processing titanium alloy described in Embodiment 1, each set of tapered protrusions includes five tapered protrusions 6, and the five tapered protrusions 6 Arranged at equal intervals along the length direction of the main cutting edge 1.

specific Embodiment approach 3

[0027] Specific embodiment three: a kind of high-strength square milling insert for processing titanium alloy described in specific embodiment one, the rake angle of the milling insert is 8°, the rear angle is 10°, the blade inclination angle is 5°, the main The deflection angle is 90°. The milling insert can achieve a large amount of cutting, and at the same time, it can reduce the effect of excessive axial pressure on the processed surface. It is suitable for cutting titanium alloy, and the milling insert has a complete structure and low processing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com