Multiscale carbon material/silicone rubber thermal interface material and preparation method

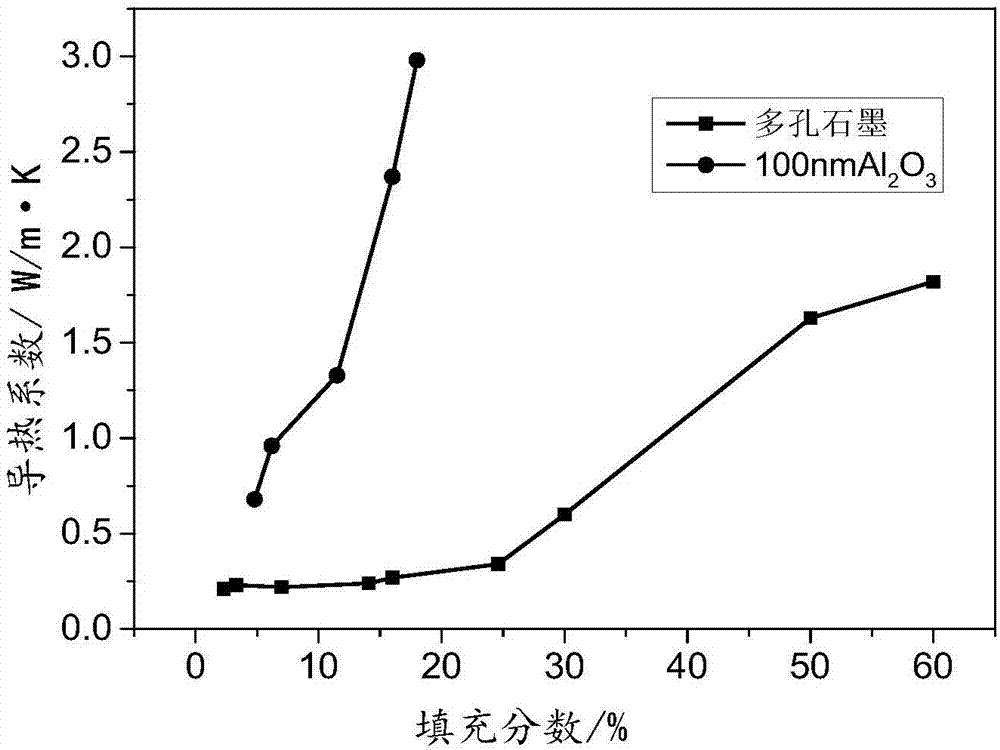

A technology of interface heat-conducting materials and carbon materials, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of reduced mechanical properties such as compression deformation capacity of composite materials, increased difficulty of mixing and vulcanization processes, and increased viscosity of the system. , to achieve the effects of improved dispersion, good compatibility and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

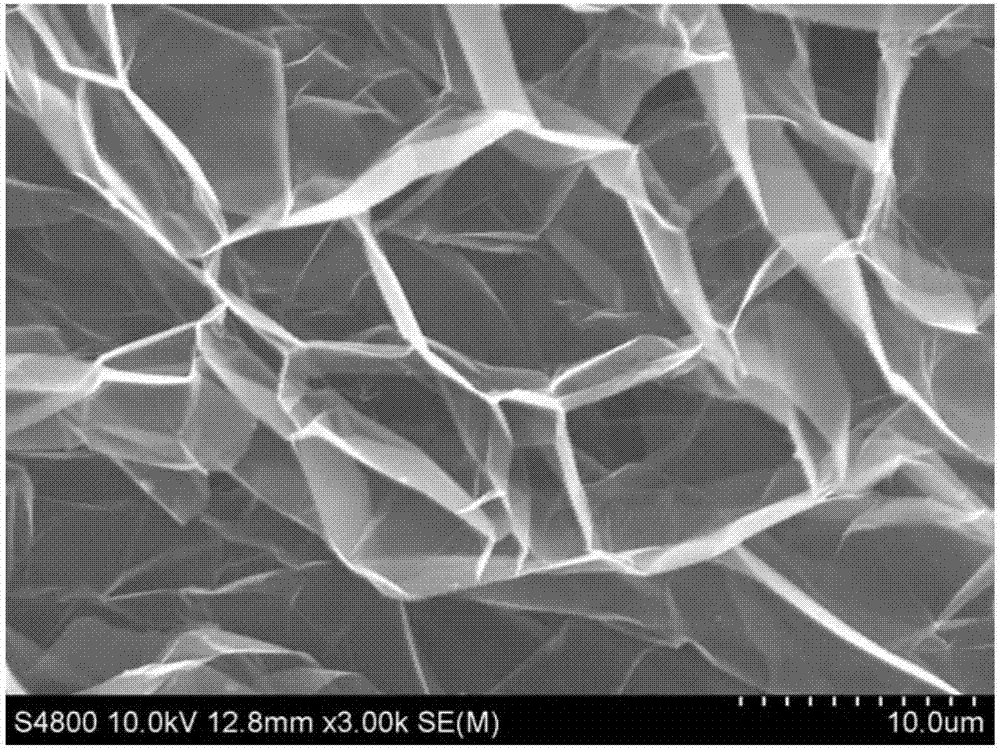

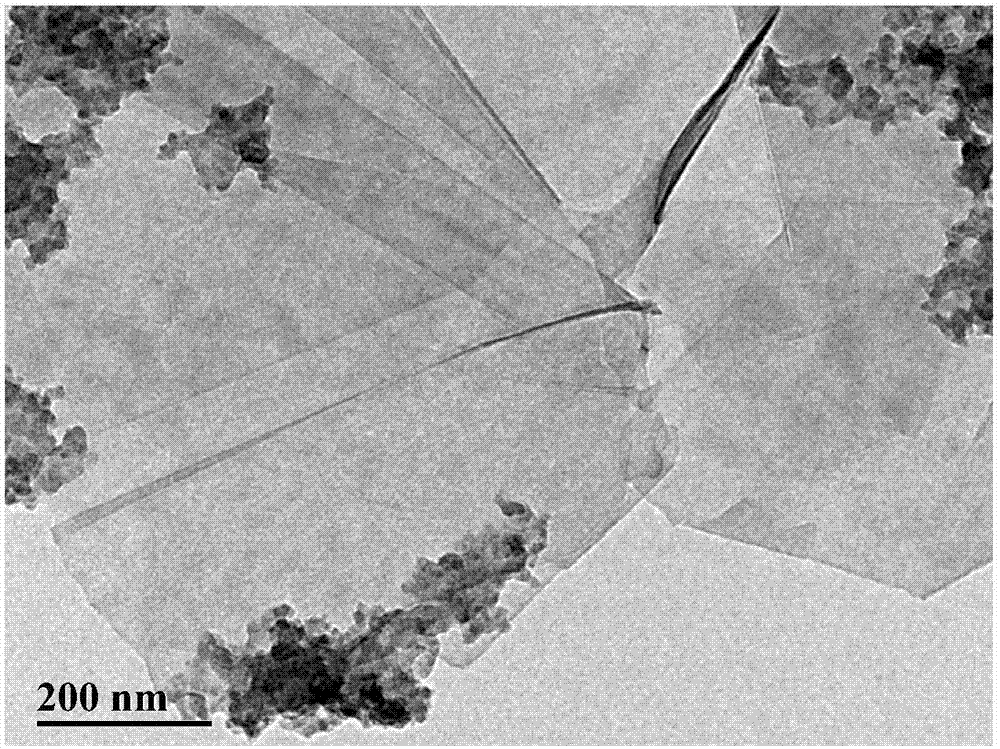

[0044] 1) Mix the dimethylsiloxane prepolymerization solution of the two-component methyl silicone resin and the crosslinking agent at a ratio of 10:1 to obtain a silicone rubber solution, and expand the expanded graphite with an expansion ratio of 250ml / g, 2.3 Graphene with a diameter of μm and the silicone rubber solution are weighed with a mass ratio of 4.8%: 0.17%: 95% for later use;

[0045] 2) The graphene and the silicone rubber solution are premixed and kneaded for 15 minutes in a vacuum kneader under vacuum conditions.

[0046] 3) Gradually add expanded graphite into the mixture obtained in step 2), and continue kneading for 30 minutes under vacuum condition.

[0047] 4) The mixture obtained in step 3) is degassed and kept at -0.085MPa pressure for 60min.

[0048] 5) Prepare the degassed composite into a thin sheet with a thickness of 1.0 mm by using a coater.

[0049] 6) The molded composite was cured at 110° C. for 45 minutes to obtain an interfacial thermally con...

Embodiment 2

[0051] 1) Mix the methyl vinyl siloxane prepolymerization solution of the two-component methyl vinyl silicone resin and the crosslinking agent at a ratio of 8:1 to obtain a silicone rubber solution, and prepare the silicone rubber solution with an expansion ratio of 250ml / g Expanded graphite, graphene with a sheet diameter of 3.5 μm and silicone rubber solution are taken by weighing with a mass ratio of 6.2%: 0.5%: 93.3% for subsequent use;

[0052] 2) The graphene and the silicone rubber solution are premixed and then placed in a vacuum pressurized stirring tank and stirred for 10 min.

[0053] 3) Add expanded graphite gradually to the mixture obtained in step 2), continue to stir for 30 minutes, and stir for 15 minutes under vacuum (-0.085 MPa) and under pressure (0.8 MPa).

[0054] 4) After the mixture obtained in step 3) is taken out of the kettle, degassing treatment is carried out, and the pressure is maintained at -0.07MPa for 120min.

[0055] 5) The degassed composite...

Embodiment 3

[0058] 1) Mix the dimethylsiloxane prepolymerization solution of the two-component dimethyl silicone resin and the crosslinking agent at a ratio of 10:1 to obtain a silicone rubber solution. Expanded graphite with expansion multiple of 300ml / g, graphene with 3.5 μm sheet diameter, and silicone rubber solution are weighed with a mass ratio of 11.6%: 1.15%: 87.2% for later use;

[0059] 2) The graphene and the silicone rubber solution are premixed and kneaded in a vacuum kneader for 30 minutes under vacuum conditions.

[0060] 3) Gradually add expanded graphite into the mixture obtained in step 2), and continue kneading for 60 min under vacuum condition.

[0061] 4) After discharging the mixture obtained in step 3), carry out degassing treatment, and keep it under the pressure of -0.09MPa for 60min.

[0062] 5) Prepare the degassed compound into a thin sheet with a thickness of 2.0 mm by using a molding die.

[0063] 6) Curing the mold at 100° C. for 60 minutes to obtain an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com