Composite material capable of resisting ageing for long time and preparation method of composite material

A composite material and anti-aging technology, which is applied in the field of composite materials and its preparation, can solve the problems of PP/GF composite material use limitation, affecting performance, easy aging of polypropylene, etc., and achieve excellent UV aging resistance and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2

[0028] A method for preparing a composite material capable of long-term aging resistance, comprising the following steps:

[0029] Prepare raw materials according to table 1, wherein, polypropylene is the copolymerized polypropylene that melt index is 27g / 10min, and glass fiber is alkali-free untwisted coarse sand glass fiber, and compatibilizer is maleic anhydride grafted polypropylene, antioxidation The agent is natural anti-oxidation masterbatch, and the lubricant is modified ethylene bis stearic acid amide TAF.

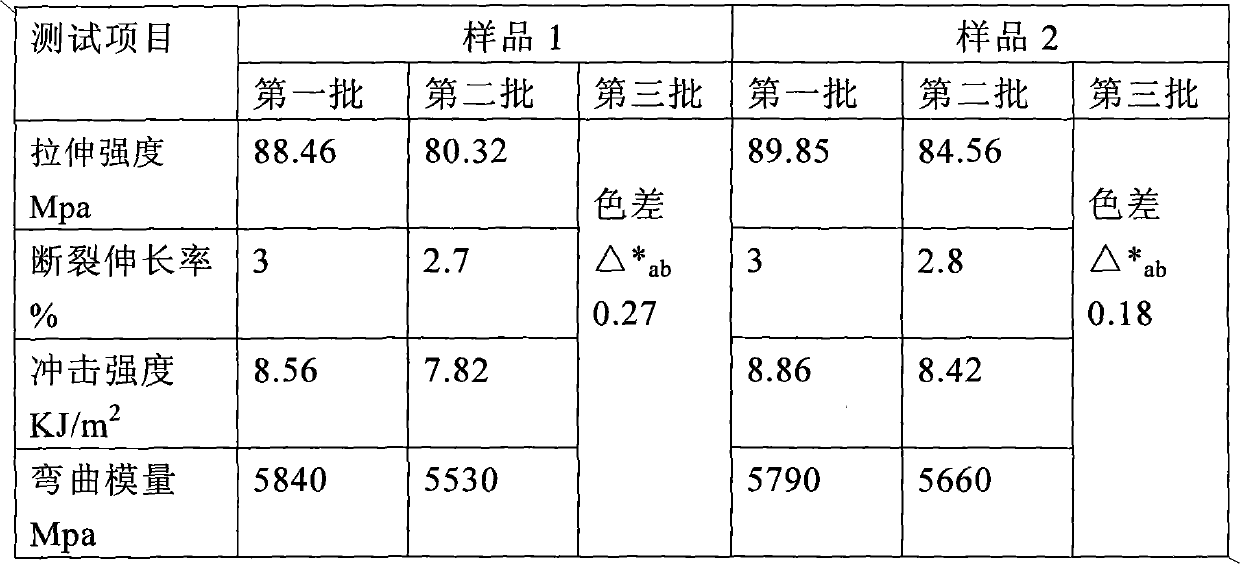

[0030] Table 1

[0031] raw material name

Example 1

Example 2

54.6

49.6

Compatibilizer

5

5

[0032] Antioxidant Masterbatch

10

15

Glass fiber GF

30

30

Lubricant TAF

0.4

0.4

[0033] Put all the components in proportion into a high mixer and mix for 2 minutes, then extrude and granulate with a screw extruder, the processi...

Embodiment 3

[0038] A method for preparing a composite material capable of long-term aging resistance, comprising the following steps:

[0039] (1) Weigh raw materials according to the following composition ratio: polypropylene 45kg, glass fiber 40kg, compatibilizer 4.9kg, antioxidant 10kg, lubricant 0.1kg, wherein, polypropylene is a copolymer with a melt index of 27g / 10min Propylene, glass fiber is alkali-free untwisted coarse sand glass fiber, compatibilizer is maleic anhydride grafted polypropylene, antioxidant is natural anti-oxidation masterbatch, lubricant is modified ethylene bis stearic acid amide TAF;

[0040] (2) Put the above-mentioned raw materials into a high mixer and mix them for 2 minutes before discharging;

[0041] (3) Put the mixed raw materials into a twin-screw extruder to granulate, control the rotating speed of the screw machine to 300 rpm, and the temperature to 220° C. After melting, extrude and granulate to obtain the product.

Embodiment 4

[0043] A method for preparing a composite material capable of long-term aging resistance, comprising the following steps:

[0044] (1) Weigh raw materials according to the following composition ratio: polypropylene 75kg, glass fiber 10kg, compatibilizer 3kg, antioxidant 11.5kg, lubricant 0.5kg, wherein, polypropylene is a copolymer with a melt index of 27g / 10min Propylene, glass fiber is alkali-free untwisted coarse sand glass fiber, compatibilizer is maleic anhydride grafted polypropylene, antioxidant is natural anti-oxidation masterbatch, lubricant is modified ethylene bis stearic acid amide TAF

[0045] (2) Put the above-mentioned raw materials into the high mixer and mix them for 3 minutes before discharging;

[0046] (3) Put the mixed raw materials into a twin-screw extruder to granulate, control the rotating speed of the screw machine to 600 rpm, and the temperature to 200° C. After melting, extrude and granulate to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com