Thermoplastic resin composition, preparation method and applications thereof

A thermoplastic resin and composition technology, applied in the field of thermoplastic resin composition and its preparation, can solve the problems of mechanical performance, thermal performance attenuation, unfavorable long-term thermal oxygen stability of polyamide composition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

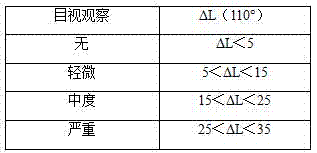

Image

Examples

Embodiment 1-9 and comparative example 1-9

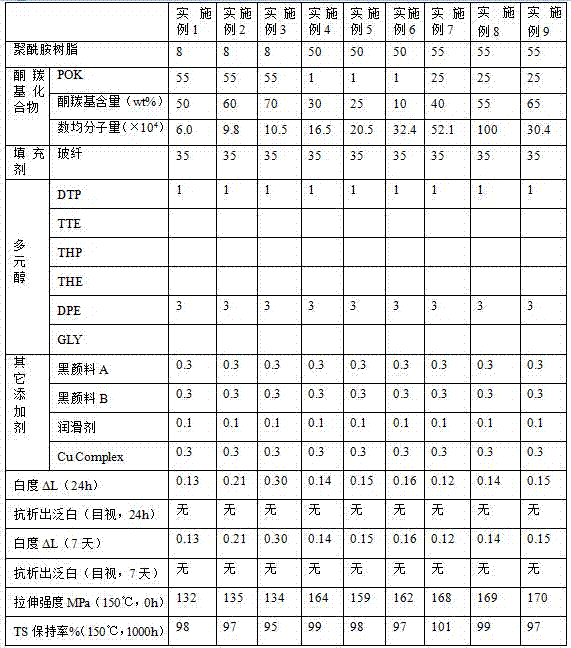

[0094] Example 1-9 and Comparative Example 1-9: Preparation of thermoplastic resin composition

[0095] The polyamide resin is dried to a moisture content of less than 1500ppm; the dried polyamide resin, polyol, ketone carbonyl compound, filler and other additives are blended according to the ratio in Table 2, and then passed through a twin-screw extruder at 220 Extrusion, cooling, and pelletizing at a temperature of ℃-280℃ to obtain a thermoplastic resin composition; the ketone carbonyl content of the thermoplastic resin composition, the anti-precipitation whitening characterization, the TS retention after aging, and the test results are shown in Table 2 .

[0096] Table 2 Specific proportions (parts by weight) of Examples 1-9 and Comparative Examples 1-9 and their test performance results

[0097]

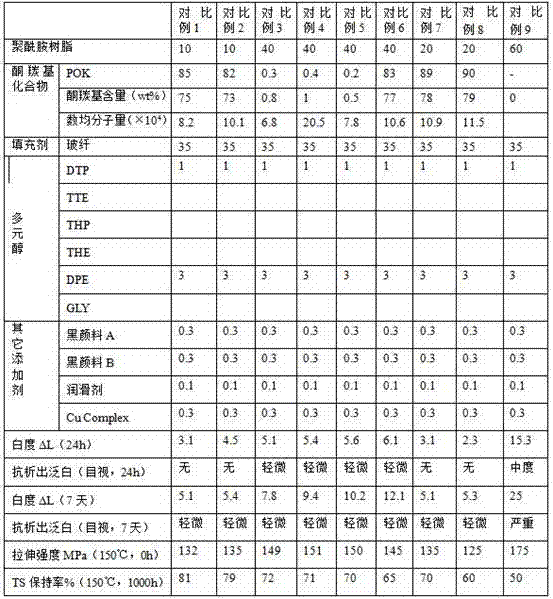

[0098] Continued Table 2

[0099]

[0100] It can be seen from Examples 1-9 and Comparative Examples 1-9 in Table 2 that the thermoplastic resin composition prepared by adding a ketone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com