Organic silicon gel composition for high-power LED (light-emitting diode) packaging

A technology of LED packaging and composition, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as small adhesion, cracking, and large adhesion, achieve excellent heat and oxygen aging resistance, and improve light extraction efficiency , the effect of high adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 3

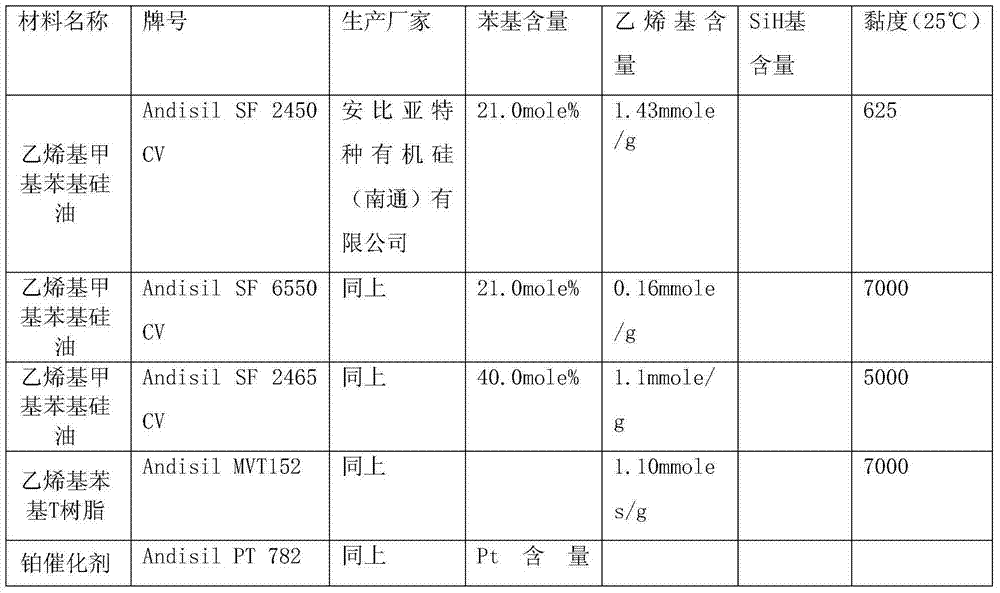

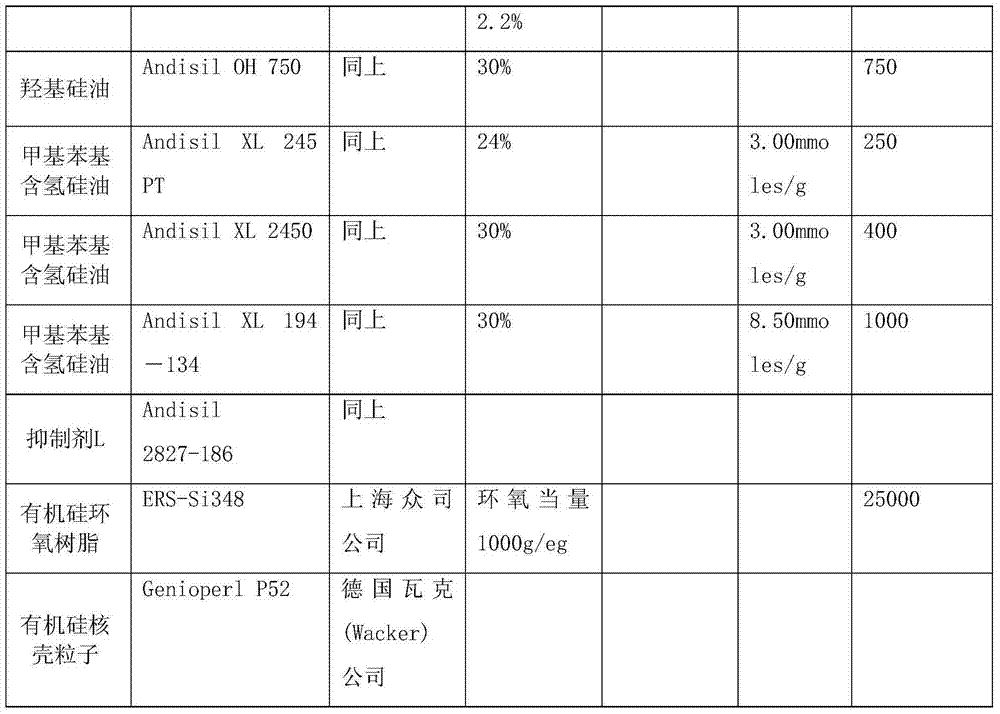

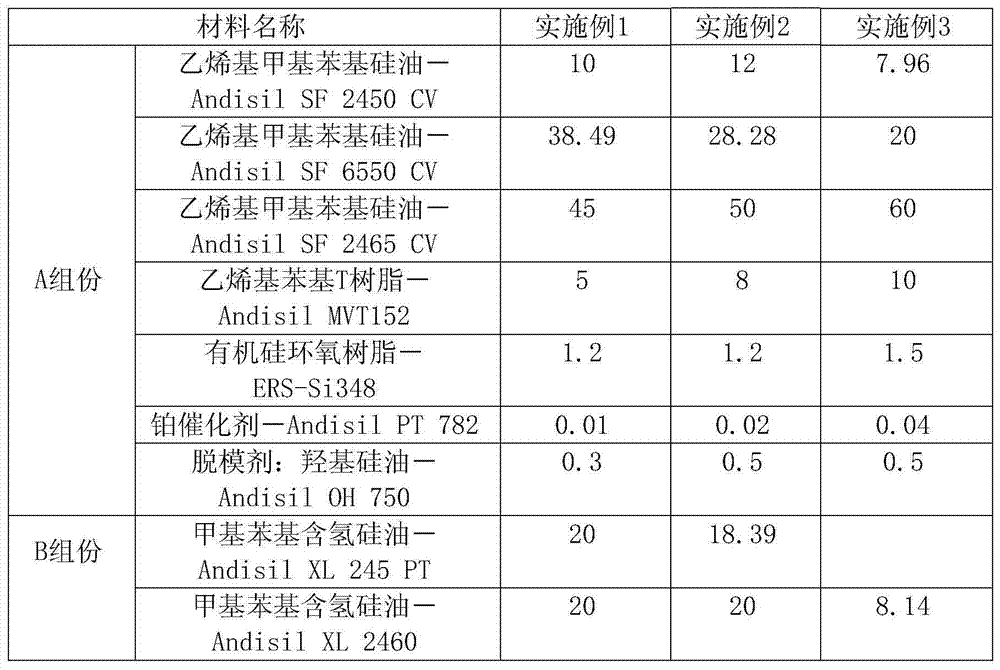

[0037]The formula of embodiment 1 to 3 is shown in Table 2, specifically as follows:

[0038] The formula of table 2 embodiment 1 to 3 (the consumption of raw material is percentage by weight in each embodiment)

[0039]

[0040]

[0041] The performance of embodiment 1 to 3 and comparative example is shown in table 3, specifically as follows:

[0042] The performance of table 3 comparative example and embodiment

[0043]

[0044] The comparative example in Table 3: it is the same type of silicone gel that is commercially available.

[0045] It can be seen from Table 3 that the silicone gel material of the embodiment of the present invention has a relatively high refractive index and light transmittance, has a strong adhesion to the PPA support, and has excellent heat and oxygen aging resistance, and is especially suitable for white light. The preparation of fluorescent powder for LED packaging, so as to improve the light extraction efficiency of LED for lighting. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com