35kV environmentally-friendly intermediate-pressure ethylene-propylene insulation material and preparation method thereof

An ethylene-propylene insulating and environmentally friendly technology, applied in rubber insulators, organic insulators, etc., can solve problems such as lead ion dissolution, water quality and soil pollution, and achieve improved mechanical and electrical properties, low cost, heat resistance and heat resistance Effect of Oxygen Aging Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

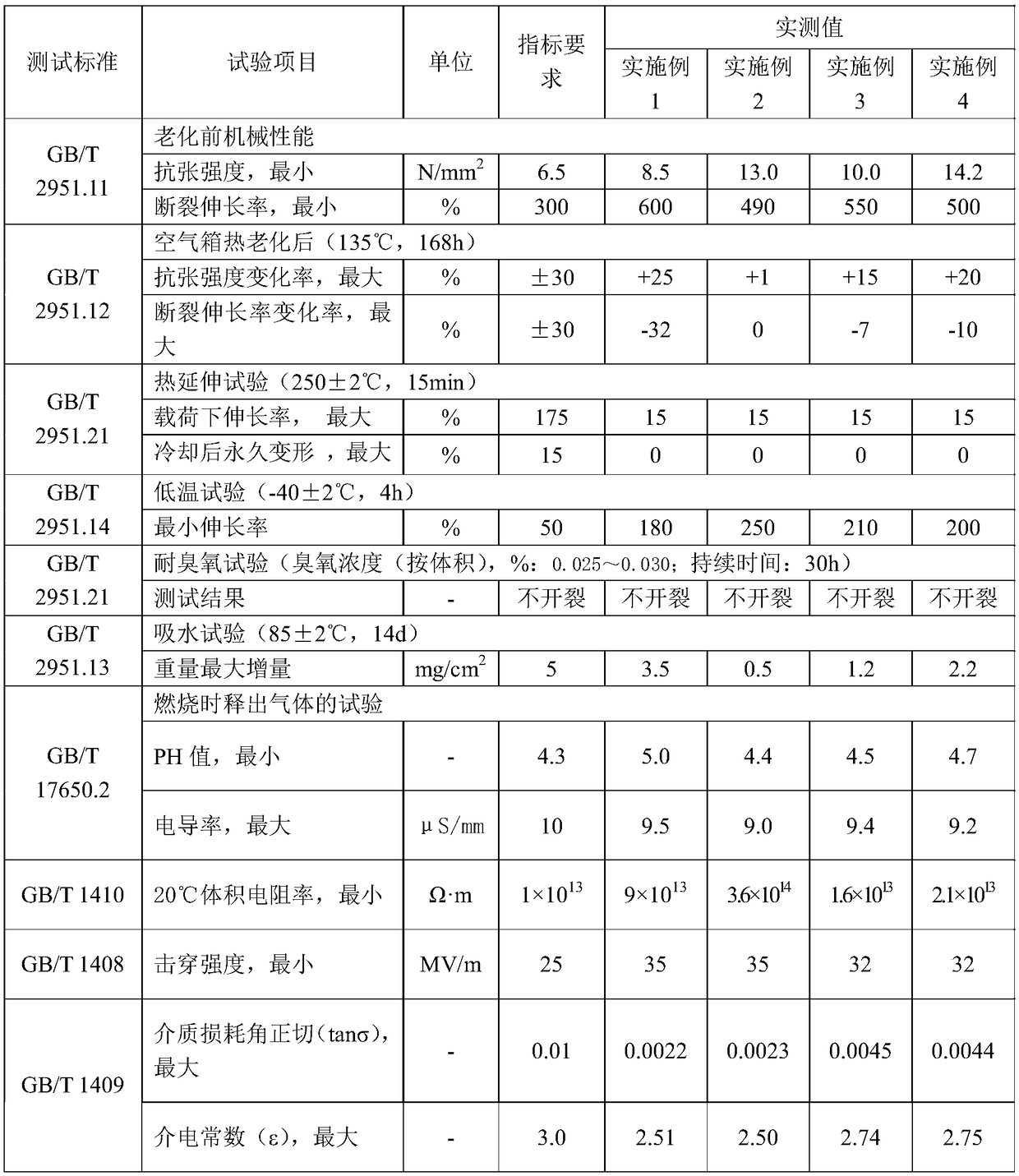

Examples

Embodiment 1

[0037] The raw material components of the 35kV environment-friendly medium-voltage ethylene-propylene insulating material are as follows (the stated parts are parts by weight):

[0038] EPDM rubber (Nordel IP 3722P of U.S. Dow Chemical Company) 90 parts,

[0039] Low-density polyethylene (Shanghai Petrochemical Q400) 10 parts,

[0040] 3.5 parts of dicumyl peroxide,

[0042] Calcined clay (BASF Translink-37) 65 parts,

[0043] 2.5 parts of 4,4'-bis(2,2-dimethylbenzyl)diphenylamine,

[0044] Paraffin wax (Daqing Petrochemical No. 58 semi-refined paraffin wax) 5 parts,

[0045] 1 part of dimethyl silicone oil (201 silicone oil, Hangzhou Yongming Silicone Co., Ltd.);

[0046] The above-mentioned parts are parts by mass.

Embodiment 2

[0048] The raw material components of the 35kV environment-friendly medium-voltage ethylene-propylene insulating material are as follows (the stated parts are parts by weight):

[0049] EPDM rubber (Nordel IP 3722P of U.S. Dow Chemical Company) 90 parts,

[0050] Low-density polyethylene (Shanghai Petrochemical Q400) 10 parts,

[0051] 3.5 parts of dicumyl peroxide,

[0052] 1 part of triallyl isocyanurate,

[0054] Calcined clay (BASF Translink-37) 65 parts,

[0055] 2.5 parts of 4,4'-bis(2,2-dimethylbenzyl)diphenylamine,

[0056] Paraffin wax (Daqing Petrochemical No. 58 semi-refined paraffin wax) 5 parts,

[0057] 1 part of dimethyl silicone oil (201 silicone oil, Hangzhou Yongming Silicone Co., Ltd.);

[0058] The above-mentioned parts are parts by mass.

Embodiment 3

[0060] The raw material components of the 35kV environment-friendly medium-voltage ethylene-propylene insulating material are as follows (the stated parts are parts by weight):

[0061] EPDM rubber (Vistalon 722 of Exxon Mobil Corporation) 90 parts,

[0062] Low-density polyethylene (Yanshan Petrochemical 1c7A) 10 parts,

[0063] 3.5 parts of dicumyl peroxide,

[0064] 1 part of triallyl isocyanurate,

[0066] Calcined clay (BASF Translink-37) 80 parts,

[0067] 2.5 parts of 4,4'-bis(2,2-dimethylbenzyl)diphenylamine,

[0068]Paraffin wax (Daqing Petrochemical No. 58 semi-refined paraffin wax) 5 parts,

[0069] 1 part of dimethyl silicone oil (201 silicone oil, Hangzhou Yongming Silicone Co., Ltd.);

[0070] The above-mentioned parts are parts by mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com