Thermo-oxidative-aging-resistant impact-resistant polypropylene composition and preparation method thereof

A technology of polypropylene composition and polypropylene powder, which is applied in the field of polyolefin composition, can solve the problems of poor aging resistance, failure to point out the effect of compounding new catalysts and other additives, etc., and achieve rigidity stability, impact improvement, Effect of improving heat and oxygen aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

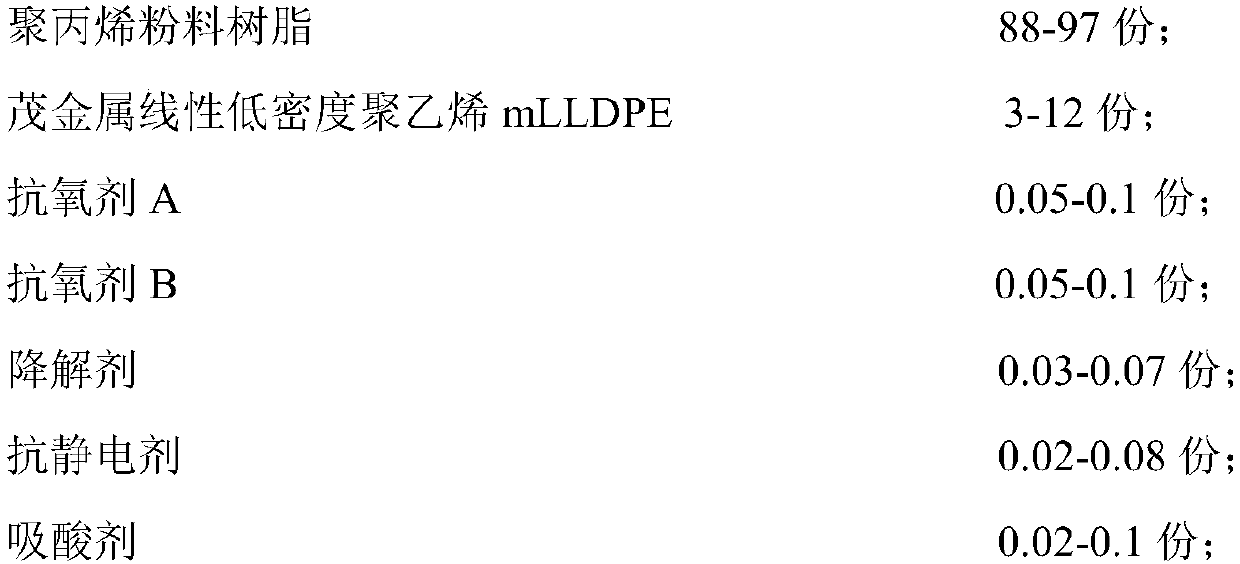

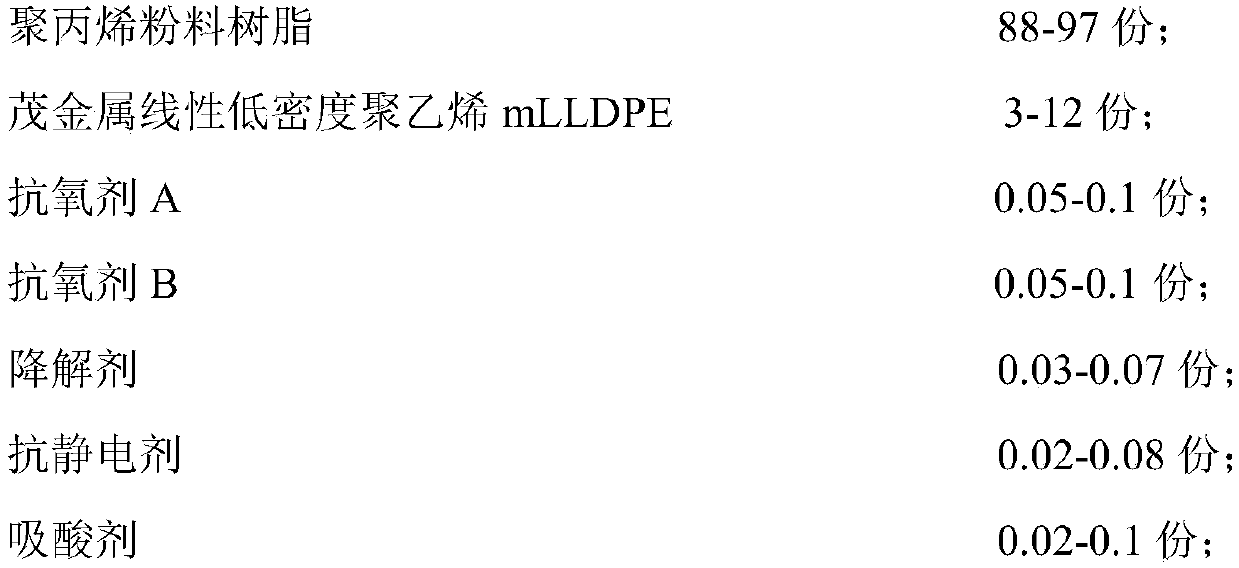

Method used

Image

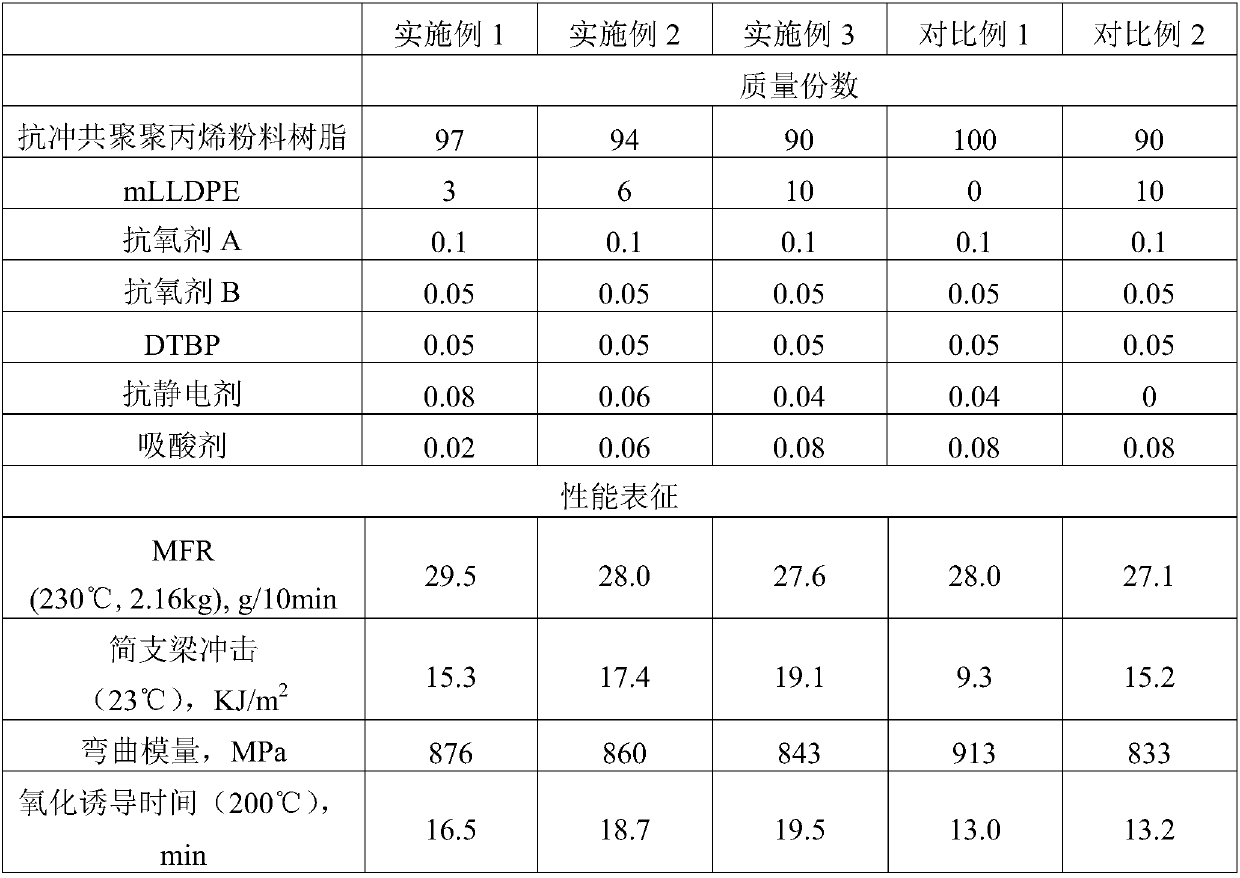

Examples

Embodiment Construction

[0035] The present invention is further described below in conjunction with embodiment.

[0036] The raw material that adopts in the embodiment and comparative example:

[0037] Impact copolymer polypropylene powder resin (melt mass flow rate 20g / 10min, melting temperature 165°C, ethylene content 5.5%);

[0038] Metallocene linear low density polyethylene mLLDPE (melt mass flow rate 3.5g / 10min, density 0.927g / cm 3 );

[0039] Antioxidant A (acrylic acid thiol, number average molecular weight is 1305);

[0040] Antioxidant B (tris(2,4-di-tert-butylphenyl) phosphite);

[0041] The degradation agent DTBP (di-tert-butyl peroxide, the number average molecular weight is 146, the density is 0.796g / cm 3 , boiling point 110°C);

[0042] Antistatic agent (glycerol monostearate);

[0043] Acid absorbing agent (calcium stearate).

[0044] The preparation method adopted in the embodiment is as follows:

[0045] Put the raw materials in a high-speed mixer, stir for 3 minutes at a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com