Addition type liquid silicone rubber with high transparency and resistance to thermo-oxidative aging, and preparation method thereof

A liquid silicone rubber, addition-type technology, applied in the field of heat-resistant oxygen aging modification of silicone polymer materials, can solve the problem of deterioration of silicone rubber transparency, processing performance and mechanical properties, and poor compatibility between metal oxides and polymer matrix and other problems, to achieve excellent thermal stability, improve thermal stability and thermal oxygen aging resistance, and high heat resistance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 11.54g octaphenylbicyclooctasiloxane tetrasilanol sodium salt (Na 4 o 14 Si 8 (C 6 h 5 ) 8 ) was dispersed in 200g of methanol, and then 2.56g of zirconium tetrachloride (ZrCl 4 ), stirred at 60°C for 12h, filtered with suction, washed 3 times with 100mL of methanol, and dried in vacuum at 50°C for 24h to obtain zirconium metal hybrid cage silsesquioxane (Zr-POSS), whose structural formula is as follows:

[0038]

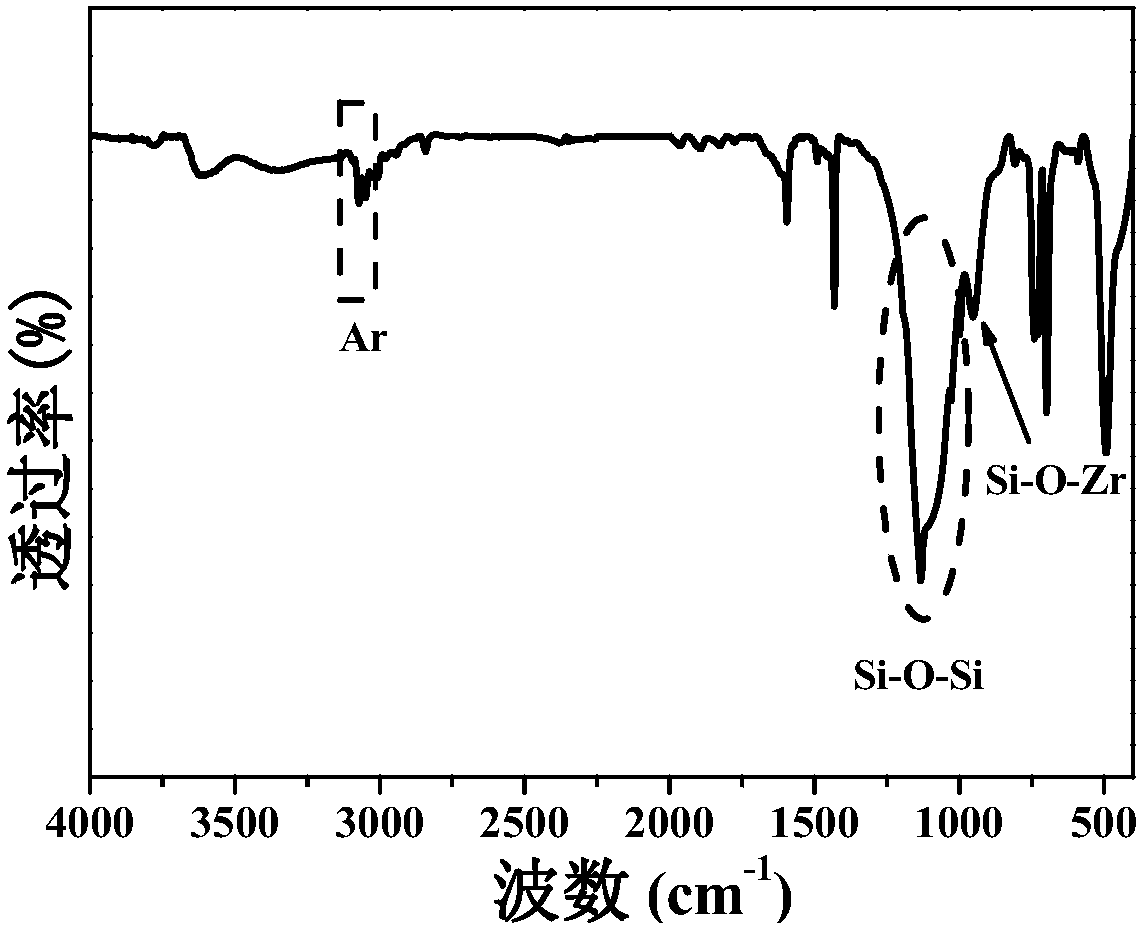

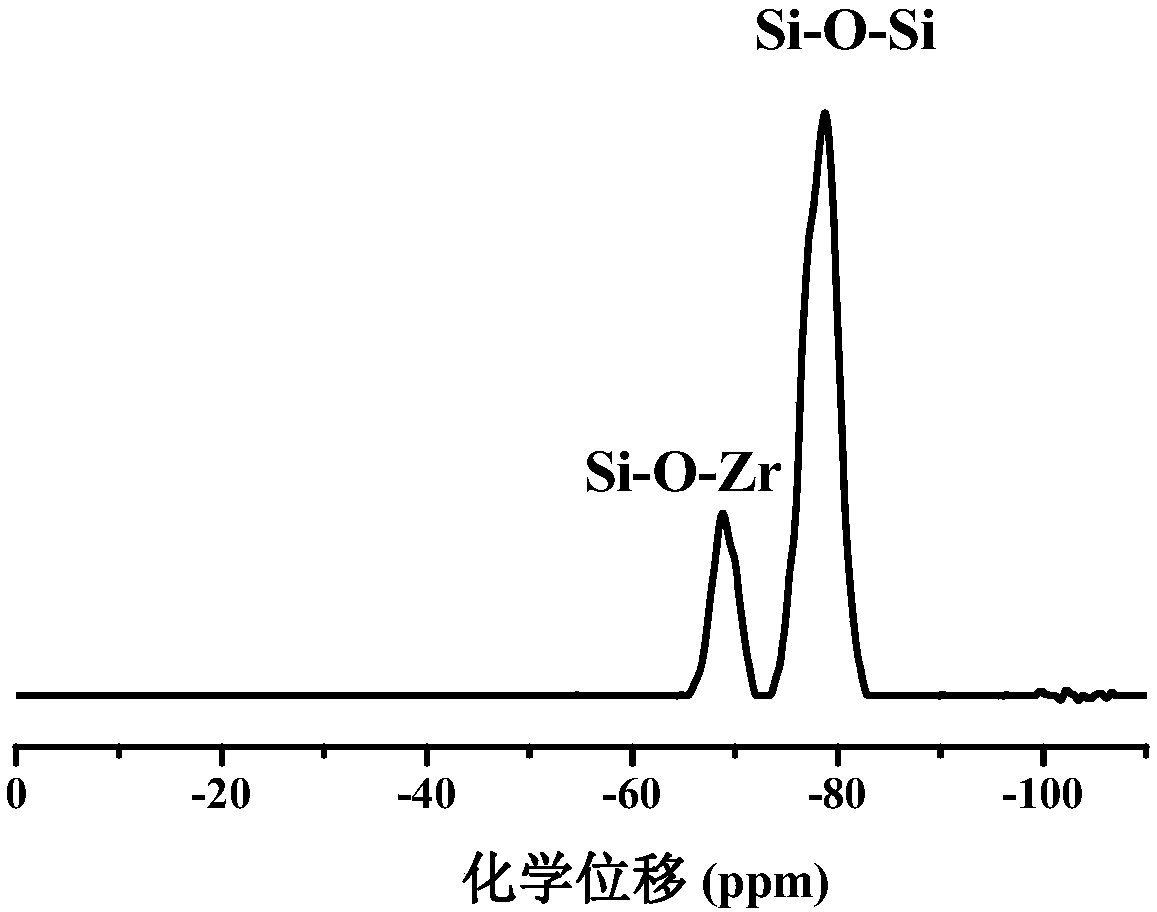

[0039] The Zr-POSS that embodiment 1 obtains is carried out infrared spectrum and nuclear magnetic resonance silicon spectrum analysis, and result is as follows figure 1 and 2 shown. It can be seen from the infrared spectrum that Zr-POSS mainly has the following characteristic peaks: 3073 and 3051cm -1 (υ Ar-H ), 1594cm -1 (υ C=C ), 1200~1000cm -1 (υ Si-O-Si ) and 954cm -1 (υ Si-O-Zr ). Such as figure 2 Shown, in the nuclear magnetic resonance silicon spectrum of Zr-POSS: (1) δ=-68.86ppm belongs to Si atom on Si-O-Zr; (2) δ=-78.84ppm belo...

Embodiment 2

[0046] 11.54g octaphenylbicyclooctasiloxane tetrasilanol sodium salt (Na 4 o 14 Si 8 (C 6 h 5 ) 8 ) was dispersed in 200g of ethanol, and then 1.90g of titanium tetrachloride (TiCl 4 ), stirred at 60°C for 12h, filtered with suction, washed 3 times with 100mL of methanol, and dried in vacuum at 50°C for 24h to obtain the titanium metal hybrid cage silsesquioxane (Ti-POSS). IR and NMR results indicated that Ti-POSS was successfully synthesized.

[0047]

[0048] In terms of parts by mass, 98 parts of vinyl-terminated polydimethylsiloxane (viscosity at 25°C is 24200mPa·s, vinyl content is 0.25mol%), 2 parts of vinyl-terminated polymethylvinyl Siloxane (viscosity at 25°C is 2095mPa·s, vinyl content is 8.7mol%), 40 parts fumed silica (specific surface area 200m 3 / g, particle size 50nm) and 6 parts of hexamethyldisilazane were added to a vacuum kneader, mixed at room temperature for 3 hours, heated to a material temperature of 160°C for 2 hours, vacuumed and mixed for 1 ...

Embodiment 3

[0052] 11.54g octaphenylbicyclooctasiloxane tetrasilanol sodium salt (Na 4 o 14 Si 8 (C 6 h 5 ) 8 ) was dispersed in 200g of ethanol, and then 2.47g of cerium trichloride (CeCl 3 ), stirred at 60°C for 12h, filtered with suction, washed 3 times with 100mL of methanol, and dried in vacuum at 50°C for 24h to obtain the cerium metal hybrid cage silsesquioxane (Ce-POSS). IR and NMR results showed that Ce-POSS was successfully synthesized.

[0053]

[0054] In terms of parts by mass, 98 parts of vinyl-terminated polydimethylsiloxane (viscosity at 25°C is 24200mPa·s, vinyl content is 0.25mol%), 2 parts of vinyl-terminated polymethylvinyl Siloxane (viscosity at 25°C is 2095mPa·s, vinyl content is 8.7mol%), 40 parts fumed silica (specific surface area 200m 3 / g, particle size 50nm) and 6 parts of hexamethyldisilazane were added to a vacuum kneader, mixed at room temperature for 3 hours, heated to a material temperature of 160°C for 2 hours, vacuumed and mixed for 1 hour, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com