Polyimide/graphite hybrid material with high dielectric constant and preparation method thereof

A high dielectric constant, polyimide technology, used in multilayer capacitors, thin film/thick film capacitors, etc., can solve the problems of flexibility and mechanical properties of composite materials, and maintain flexibility and excellent mechanical properties. The effect of low content and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 0.053g of natural flake graphite, sodium nitrate, and potassium permanganate into 98% concentrated sulfuric acid placed in an ice bath, keep stirring for 1 hour, and prevent the temperature of the mixture from exceeding 20°C. The ice bath was removed, and the mixture was kept in a water bath at 35°C for 4 hours. Dilute with deionized water and keep the mixture at 90°C for 15 minutes. Then dilute with deionized water, add hydrogen peroxide and filter while hot. Wash with deionized water until SO-free 4 2- ions to obtain 0.10g graphite oxide.

[0036] (2) 0.10g of graphite oxide was dispersed in 81ml of N-methylpyrrolidone, and ultrasonically dispersed for 15 hours at room temperature to make it uniformly dispersed to become a graphite oxide dispersion;

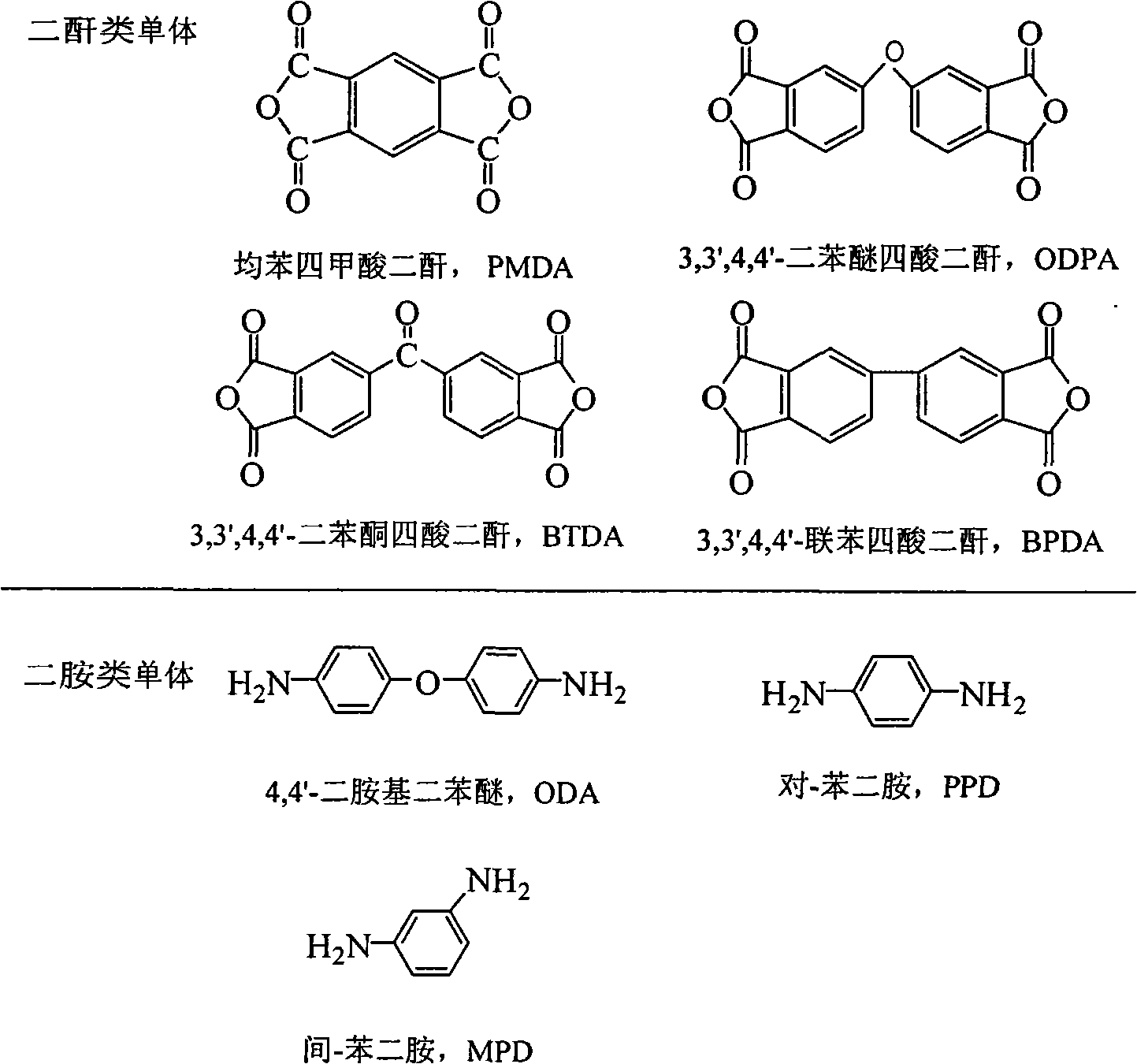

[0037] (3) Under the protection of an inert gas, add 5.0g of 4,4'-diaminodiphenyl ether (ODA) into the above-mentioned graphite oxide dispersion, stir, and slowly add 5.6g of pyromellitic acid to it after dis...

Embodiment 2

[0045] (1) According to the method in the embodiment 1 step (1), 0.082g of natural flake graphite was oxidized and exfoliated to obtain 0.164g of graphite oxide.

[0046] (2) 0.032g of graphite oxide is dispersed in 84ml of N,N-dimethylacetamide, and ultrasonicated for 3 hours at room temperature to make it uniformly dispersed to become a graphite oxide dispersion;

[0047] (3) Under the protection of an inert gas, add 2.7g m-phenylenediamine (MPD) into the above-mentioned graphite oxide dispersion, stir, and slowly add 8.2g 3,3',4,4'-bis benzophenone tetra-acid dianhydride (BTDA); after the addition is completed, react at 27° C. for 15 hours under the protection of an inert gas to obtain a polyamic acid / graphite hybrid solution;

[0048] (4) The obtained polyamic acid / graphite hybrid solution is formed into a film on a stainless steel plate, and after an imidization reaction at 320°C for 3 hours, a polyimide / graphite with a graphite content of 0.75% is obtained hybrid membra...

Embodiment 3

[0055] (1) According to the method in the embodiment 1 step (1), 0.204g of natural flake graphite was oxidized and peeled off to obtain 0.40g of graphite oxide.

[0056] (2) 0.40g of graphite oxide is dispersed in 78ml of N-methylpyrrolidone, and ultrasonicated for 9 hours at room temperature to make it uniformly dispersed to become a graphite oxide dispersion;

[0057] (3) Under the protection of an inert gas, add 2.7g of p-phenylenediamine (PPD) into the above-mentioned graphite oxide dispersion, stir, and slowly add 7.5g of 3,3',4,4'-linked pyromellitic dianhydride (BPDA); after the addition is complete, react at 20°C for 20 hours under the protection of an inert gas to obtain a polyamic acid / graphite hybrid solution;

[0058] (4) The obtained polyamic acid / graphite hybrid solution is formed into a film on a stainless steel plate, and after an imidization reaction at 350°C for 3 hours, a polyimide / graphite with a graphite content of 2% is obtained hybrid membrane.

[0059...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com