A kind of high temperature resistant halogen-free flame retardant silicone rubber and preparation method thereof

A silicone rubber and high temperature resistant technology, which is applied in the field of high temperature resistant halogen-free flame retardant silicone rubber and its preparation, can solve the problems of preparation and application research that have not been reported, limit practical application, etc., and achieve the purpose of inhibiting the degradation of snapping and reducing the impact , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

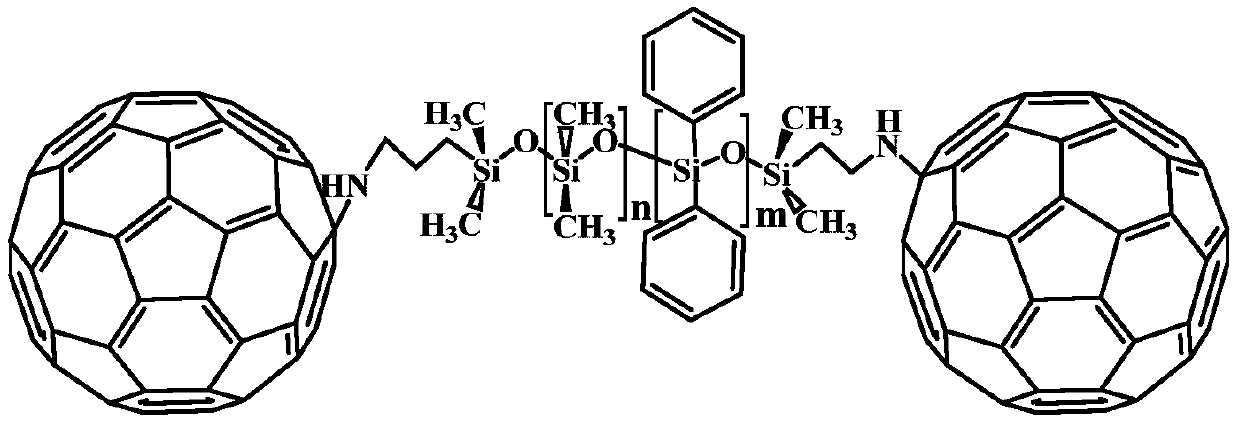

[0042] 6.00g fullerene C 60 Ultrasonic dispersion in 200mL benzene organic solvent, then add 6.00g aminopropyl polydiphenylsiloxane (viscosity at 25°C is 2000mPa·s, nitrogen content is 0.05wt%), stir at 100°C for 12h , after rotary evaporation, 100mL ethanol washing and centrifugation for 3 times, and vacuum drying at 50°C for 24h, the aminophenyl silicone oil modified fullerene 1 was obtained, its structural formula is as follows:

[0043] Where n is 40-50;

[0044] Aminophenyl silicone oil modified fullerene 1 obtained in embodiment 1 is carried out infrared spectrum analysis, and aminophenyl silicone oil modified fullerene 1 mainly has following characteristic peak: 3440cm -1 (υ N-H ), 2963cm -1 (υ C-H ), 1200~1000cm -1 (υ Si-O-Si ), 575 and 525cm -1 (υ C=C ), indicating that the aminophenyl silicone oil modified fullerene 1 was successfully synthesized.

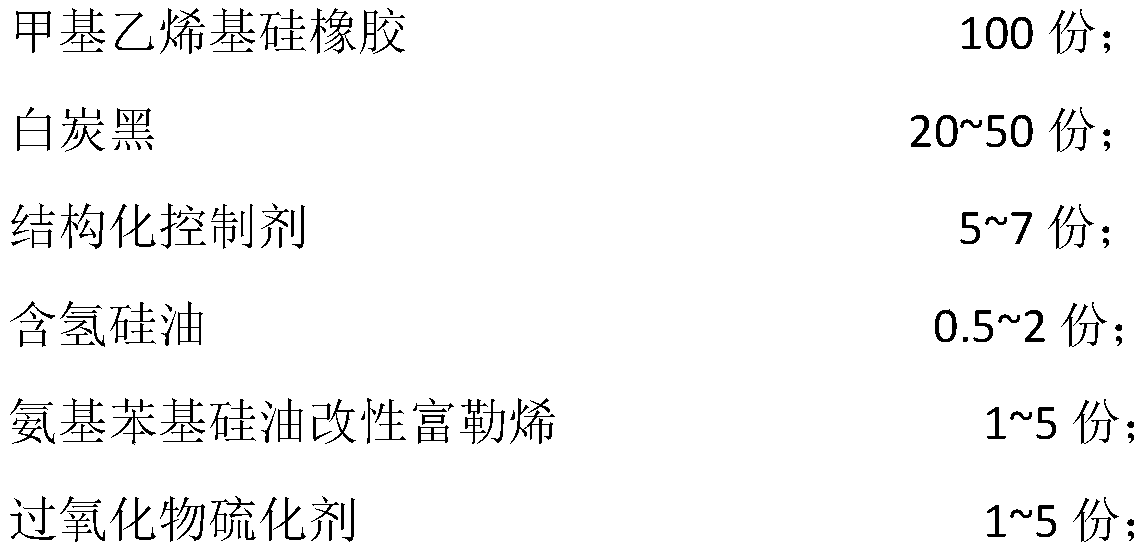

[0045] In parts by mass, 93 parts of vinyl-terminated polydimethylsiloxane (molecular weight 5.5*10 5 g / mol...

Embodiment 2

[0051] 6.00g fullerene C 60 Ultrasonic dispersion in 200mL benzene organic solvent, then add 6.00g aminopropyl polymethylphenylsiloxane (viscosity at 25°C is 500mPa·s, nitrogen content is 0.3wt%), stir at 100°C After 12 hours, rotary evaporation, 100mL ethanol washing and centrifugation for 3 times, and vacuum drying at 50°C for 24 hours, the aminophenyl silicone oil modified fullerene 2 was obtained, whose structural formula is as follows:

[0052]

[0053] Where n is 10-20, m is 5-10;

[0054] In parts by mass, 93 parts of vinyl-terminated polydimethylsiloxane (molecular weight 5.5*10 5 g / mol, vinyl content is 0.025mol%), 7 parts of polymethylvinylsiloxane (molecular weight is 5*10 5 g / mol, vinyl content is 2.03mol%), 40 parts of fumed silica (specific surface area 220m 3 / g, particle size 35nm), 0.6 parts of hydrogen-containing silicone oil (molecular weight is 3000g / mol, hydrogen content is 1.2wt%) and 6 parts of hydroxyl silicone oil (molecular weight is 450g / mol, h...

Embodiment 3

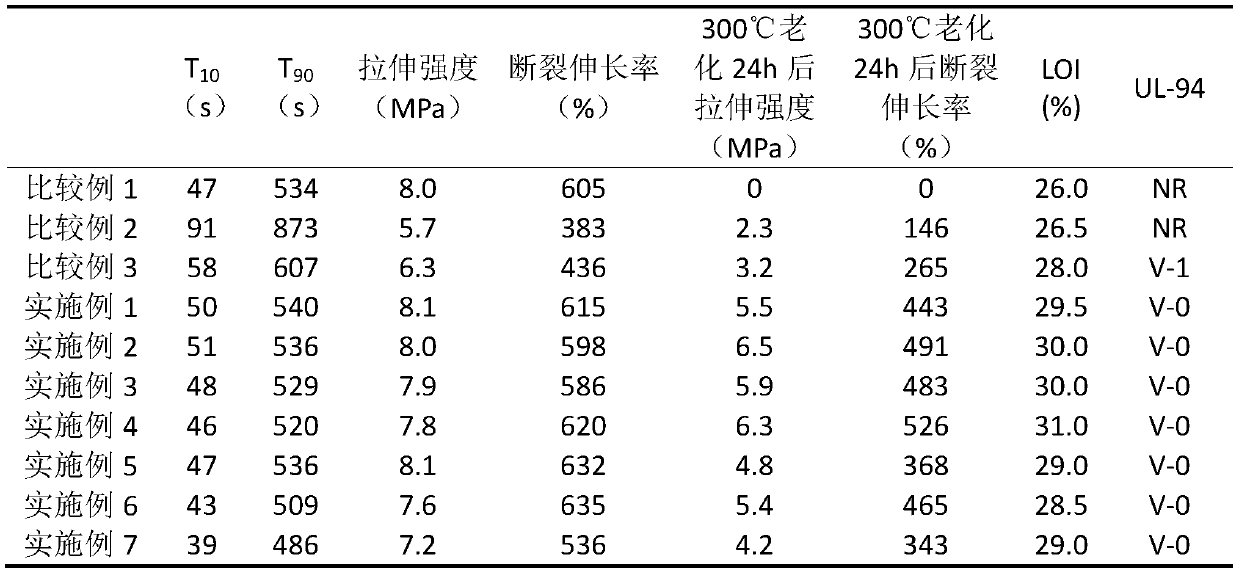

[0058] The difference between this example and Example 1 is that the amount of aminopropyl polydiphenylsiloxane is changed to 12.00 g, the benzene solvent is changed to toluene solvent, and the reaction is carried out at 110° C. for 20 hours. It can be seen from Table 1 that the vulcanization performance of silicone rubber does not change much, the highest service temperature reaches 350 °C, the tensile strength and elongation at break are maintained at 7.9MPa and 586%, respectively, and the LOI is 30.0%. The performance has passed the UL‐94V‐0 rating. After aging at 300℃ for 24h, the tensile strength and elongation at break of the silicone rubber remained at 5.9MPa and 483%, respectively. It shows that aminophenyl silicone oil modified fullerene can significantly improve the high temperature resistance and flame retardancy of silicone rubber without affecting the mechanical properties of silicone rubber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com