A kind of tread rubber for preparing high-performance tires

A high-performance tread rubber technology, which is applied in the field of rubber tires and tread rubber, can solve the problems of poor dynamic fatigue performance, poor aging retention rate, poor mechanical strength and tear performance of the tread, and improve the service life , heat aging rate improvement, low hysteresis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

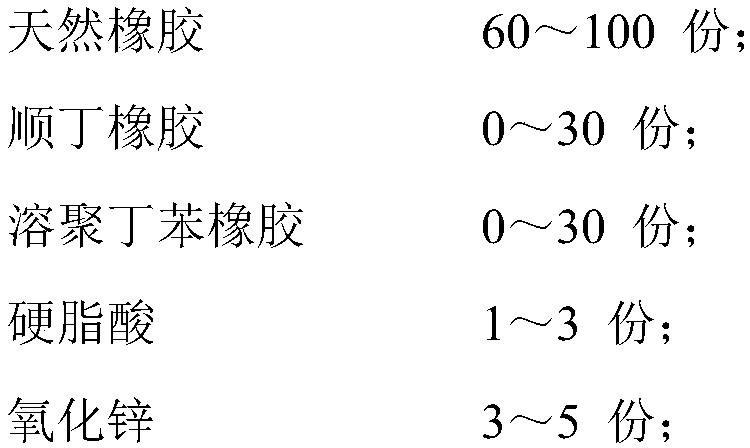

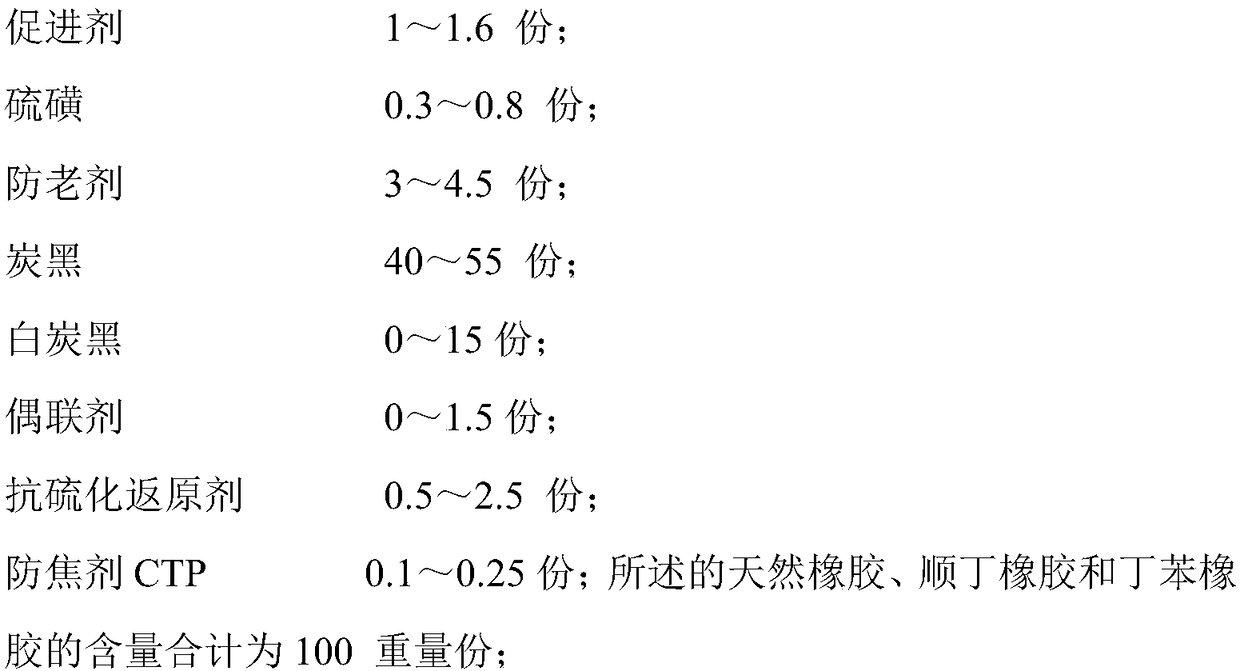

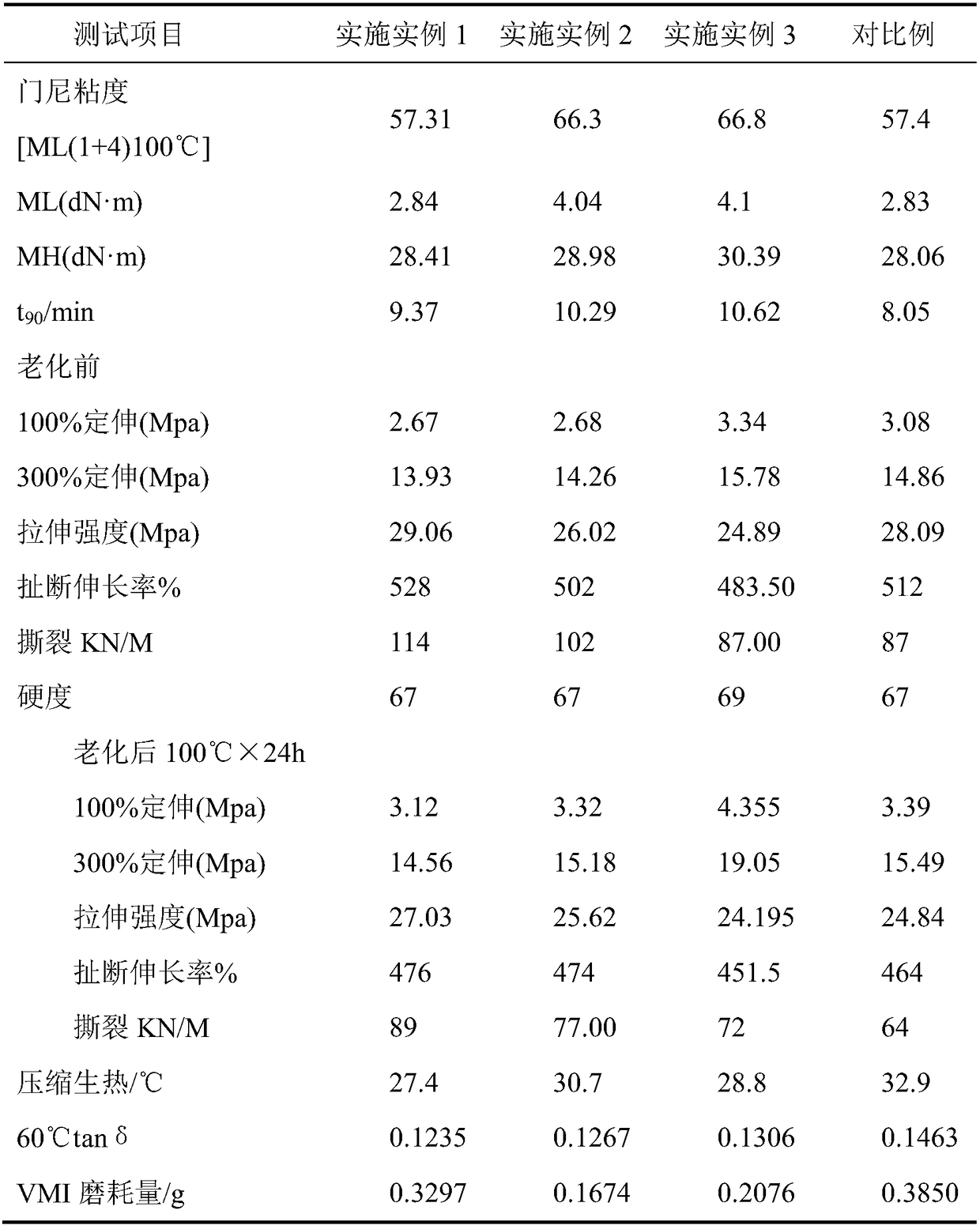

[0024] Example 1, the tread rubber used to prepare high-performance tires, each component raw material is composed of the following parts by weight: 100 parts of natural rubber, 50 parts of carbon black N234, 1.5 parts of anti-aging agent 4020, 0.5 parts of RD , 1 part of protective wax, 2 parts of stearic acid, 4 parts of ZnO, 0.7 parts of sulfur, 1.2 parts of accelerator, 0.8 parts of anti-reversion agent KA9188, and 0.15 parts of anti-scorch agent CTP.

[0025] The physical properties of the finished product are shown in Table 1 after testing

Embodiment 2

[0026] Example 2, the described tread rubber for preparing high-performance tires, each component raw material is composed of the following parts by weight: 70 parts of natural rubber, 30 parts of butadiene rubber, 47 parts of carbon black N134, white carbon black 6 parts, 1.5 parts of anti-aging agent 4020, 1 part of RD, 1 part of protective wax, 2 parts of stearic acid, 4 parts of ZnO, 0.6 parts of sulfur, 1.2 parts of accelerator NS, 1.2 parts of anti-reversion agent WY9188, anti-scorch agent CTP 0.12 copies.

[0027] The physical properties of the finished product are shown in Table 1 after testing

Embodiment 3

[0028] Embodiment 3, described a kind of tread rubber that is used to prepare high-performance tires, each component raw material is made up of following parts by weight: 60 parts of natural rubber, 20 parts of butadiene rubber, 20 parts of solution-polymerized styrene-butadiene rubber, carbon 40 parts of black N375, 15 parts of white carbon black, 1.5 parts of coupling agent Si-69, 1.5 parts of antioxidant 4020, 1 part of RD, 1 part of protective wax, 3 parts of stearic acid, 3 parts of ZnO, 0.3 parts of sulfur, accelerator 1.6 parts, anti-reversion agent 2.5 parts, anti-scorch agent CTP 0.10 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com