Hydraulic coupler

A hydraulic coupler and volute technology, which is applied in the direction of fluid transmission, belt/chain/gear, mechanical equipment, etc., can solve the problem that cannot fully meet the requirements of high-speed rail vehicles, and the hydraulic coupler has a large volume and cannot reach Use requirements and other issues to achieve the effect of compact structure, fast response speed, and satisfying power transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

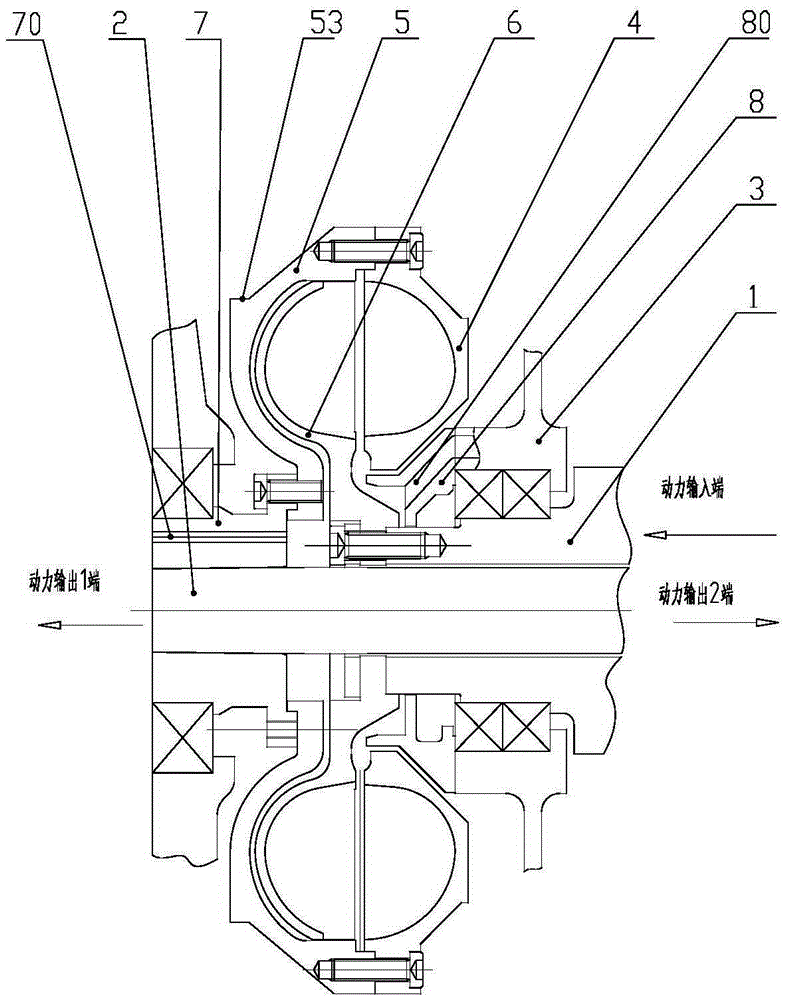

[0027] Such as Figure 1-4 The hydraulic coupling is used to connect the input shaft and the output shaft to transmit power. The input shaft 1 and the output shaft 2 are respectively supported on the box body 3 through bearings, wherein the input shaft 1 is a hollow shaft, and the output shaft 2 is a solid shaft. , the output shaft 2 is arranged inside the input shaft 1, wherein the output end of the power (that is, the output shaft) can be on the same side of the input shaft 1 or on the opposite side of the output shaft 2 .

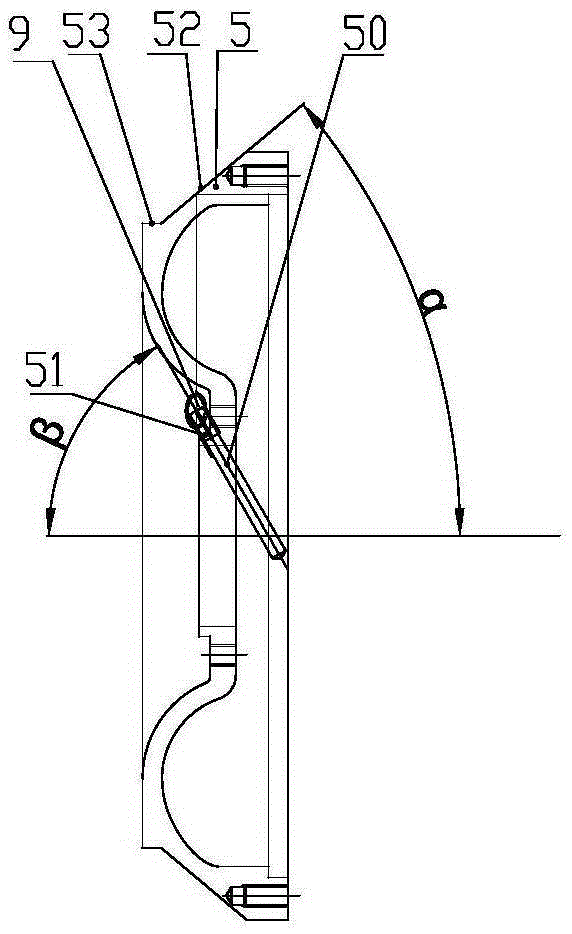

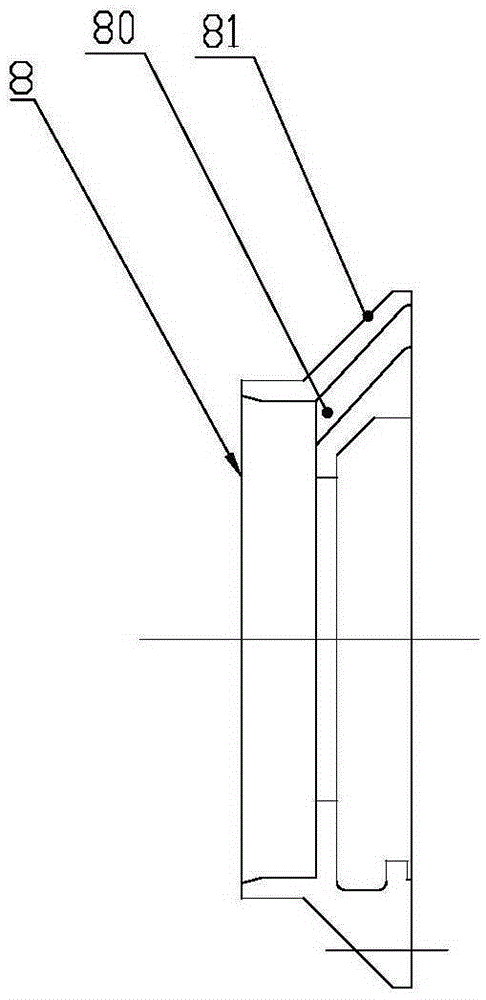

[0028] The output shaft 2 is provided with a shaft sleeve 7, and the output shaft 2 is interference fit with the shaft sleeve 7. The hydraulic coupling includes a turbine 4, a volute 5 and a pump wheel 6 installed in the cavity formed by the turbine 4 and the volute 5. , the pump impeller 6 is fixedly connected with the input shaft 1, and the turbine 4 and the shaft sleeve 7 are both fixedly connected with the volute 5.

[0029] The volute 5 is matched ...

Embodiment 2

[0034] Such as Figure 5 As shown, the only difference between Embodiment 2 of the present invention and Embodiment 1 is that the input shaft 1 is a solid shaft, and the power output end (output shaft) can only be on the opposite side of the input shaft 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com