Modified polyurethane film and application thereof

A polyurethane film and polyurethane technology, applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of functional masterbatch precipitation, limited service life, and can not fundamentally improve the low friction and temperature resistance of the surface of the conveyor belt, to achieve Fast and effective separation, improved compatibility, and low friction coefficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

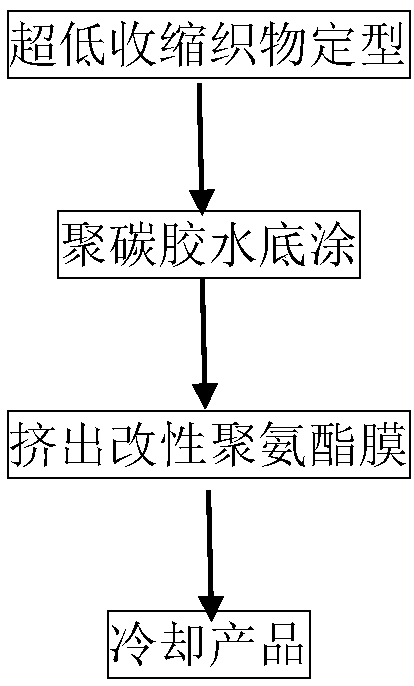

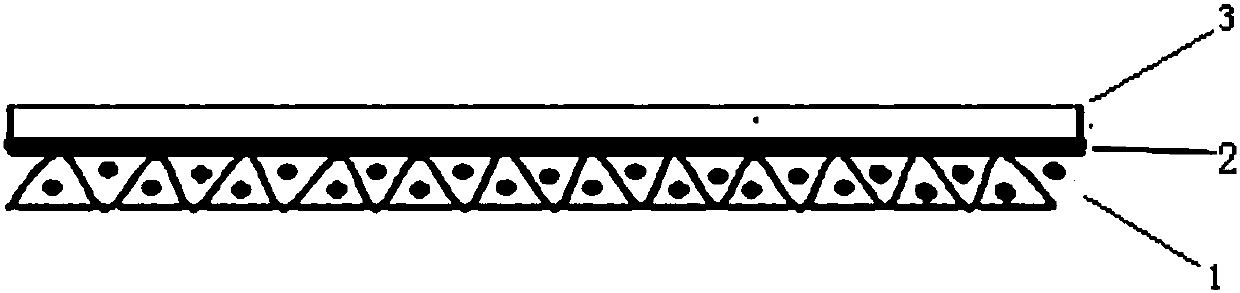

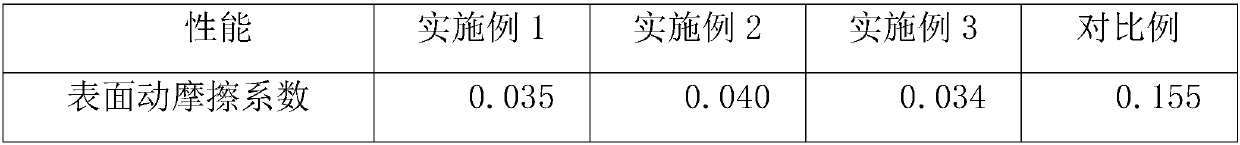

[0030] see figure 1 It is the process flow diagram and the figure 2 As shown in the structural schematic diagram of the low-friction and high-temperature-resistant TPU light-duty conveyor belt of the present invention, the manufacturing method of the low-friction and high-temperature-resistant TPU light-duty conveyor belt comprises the following steps:

[0031] S1: Ultra-low shrinkage polyester fabric shaping: the warp direction adopts low shrinkage polyester activated yarn with a linear density of 1000D, and the weft direction adopts polyester monofilament with a diameter of 0.3mm. The density is 42 threads / inch, and the weaving method is 2 / 2 broken twill. Ultra-low shrinkage polyester fabric is shaped under infrared heating conditions;

[0032] S2: Polycarbonate glue is primed on the ultra-low shrinkage polyester fabric after setting, and the surface temperature of the glue is 120-130°C to form a primer layer;

[0033] S3: Extrude a rubber-modified polyurethane film with...

Embodiment 2

[0035] see figure 1 It is the process flow diagram and the figure 2 As shown in the structural schematic diagram of the low-friction and high-temperature-resistant TPU light-duty conveyor belt of the present invention, the manufacturing method of the low-friction and high-temperature-resistant TPU light-duty conveyor belt comprises the following steps:

[0036] S1: Ultra-low shrinkage polyester fabric shaping: the warp direction adopts low shrinkage polyester activated yarn with a linear density of 1000D, and the weft direction adopts polyester monofilament with a diameter of 0.3mm. The density is 42 threads / inch, and the weaving method is 2 / 2 broken twill. Ultra-low shrinkage polyester fabric is shaped under infrared heating conditions;

[0037] S2: Polycarbonate glue is primed on the ultra-low shrinkage polyester fabric after setting, and the surface temperature of the glue is 120-130°C to form a primer layer;

[0038] S3: Extrude a rubber-modified polyurethane film with...

Embodiment 3

[0040] see figure 1 It is the process flow diagram and the figure 2 As shown in the structural schematic diagram of the low-friction and high-temperature-resistant TPU light-duty conveyor belt of the present invention, the manufacturing method of the low-friction and high-temperature-resistant TPU light-duty conveyor belt comprises the following steps:

[0041] S1: Ultra-low shrinkage polyester fabric shaping: the warp direction adopts low shrinkage polyester activated yarn with a linear density of 1000D, and the weft direction adopts polyester monofilament with a diameter of 0.3mm. The density is 42 threads / inch, and the weaving method is 2 / 2 broken twill. Ultra-low shrinkage polyester fabric is shaped under infrared heating conditions;

[0042] S2: Polycarbonate glue is primed on the ultra-low shrinkage polyester fabric after setting, and the surface temperature of the glue is 120-130°C to form a primer layer;

[0043]S3: Extrude a rubber-modified polyurethane film with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com