A method for reducing the pressure of pump sealing chamber

A sealing cavity and pressure technology, which is applied to components, pumps, and pump components of elastic fluid pumping devices, can solve the problem of high pressure in the sealing cavity, and achieve the effects of reducing investment, reducing pressure, and reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

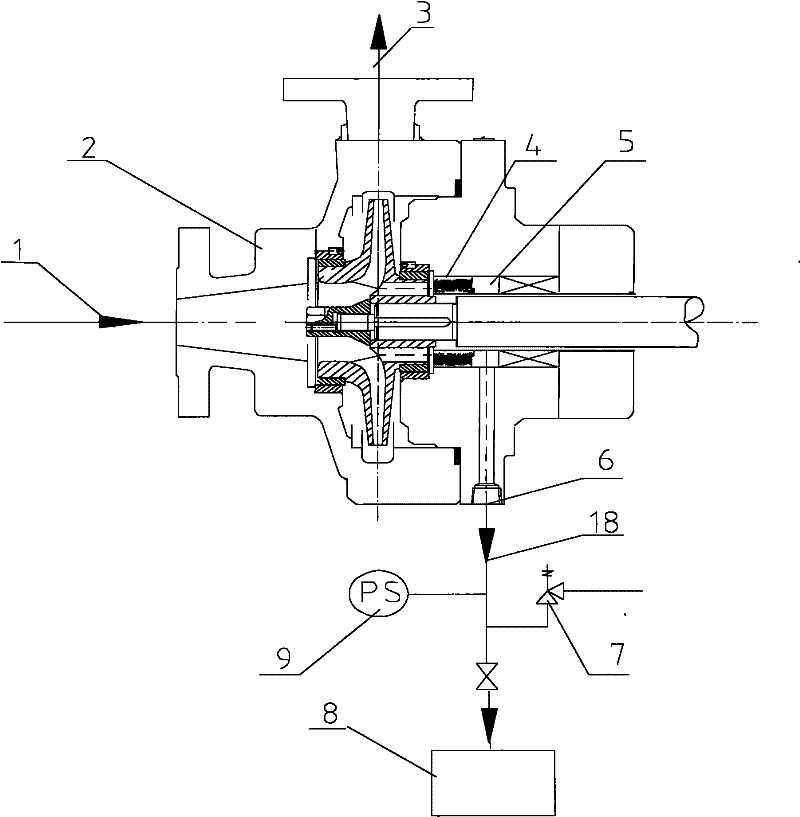

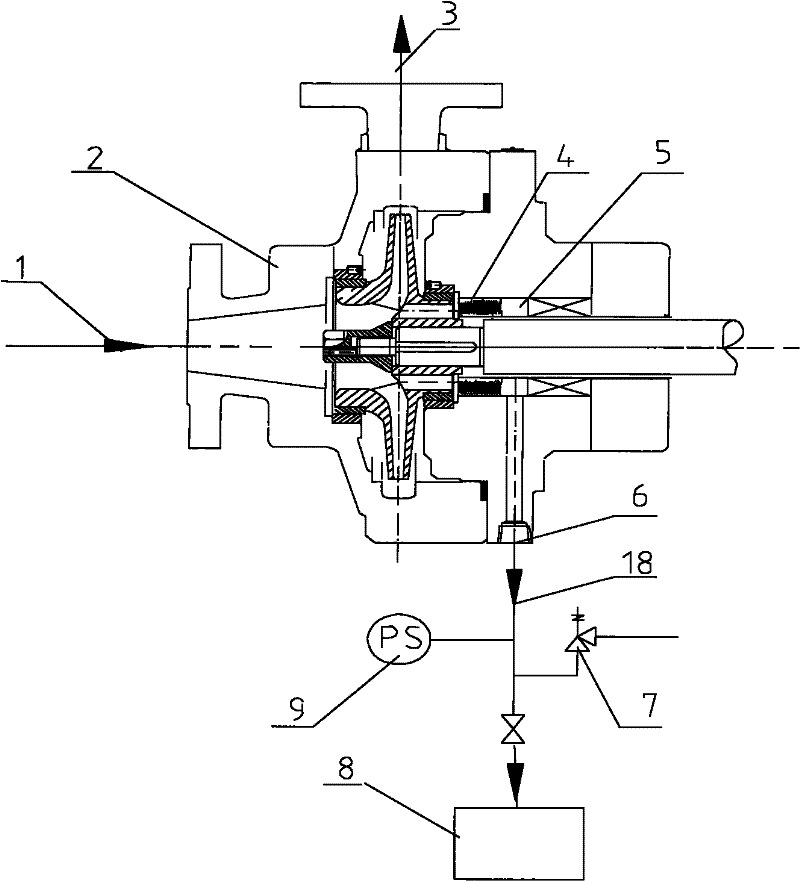

[0037] Such as figure 1 As shown, the high-pressure fluid 1 with a pressure of 4.0-35.0MPa enters the pump body 2, and is discharged from the pump body 2 after pressurization, becoming a high-pressure flow 3, and the liquid discharged from the balance drum or throttling bush 4 arranged in front of the sealing chamber 18 leads to the pressure of 0.1 ~ 4.0MPa low-pressure container 8 through the liquid outlet 6.

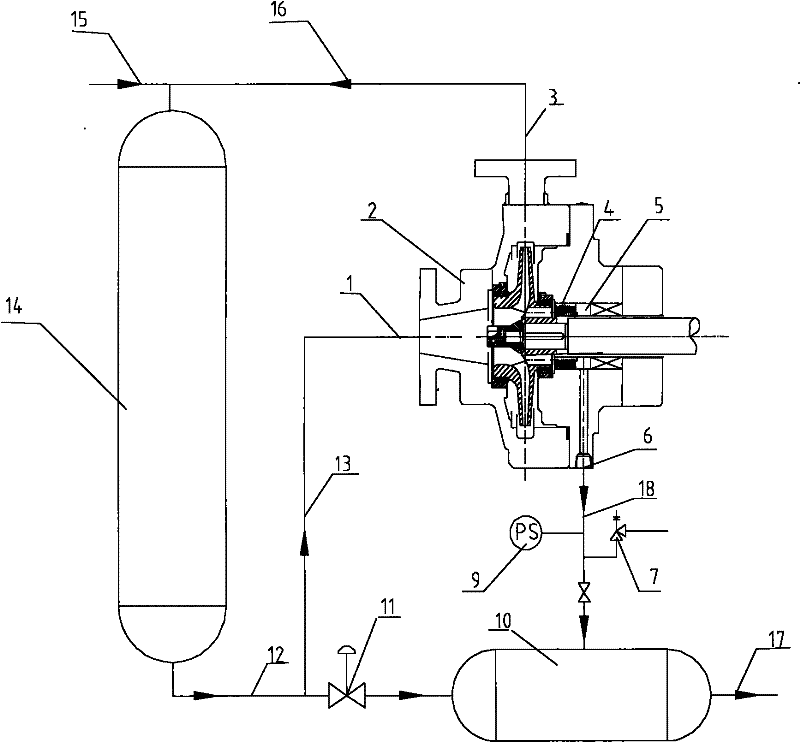

[0038] figure 2 As shown, part of the reaction effluent 13 from the high-pressure hydrogenation reactor with a pressure of 7.0-20.0 MPa enters the pump body 2, and is discharged from the pump body 2 after being pressurized to become a high-pressure stream 16. The high-pressure stream 16 is combined with the new hydrogenation raw material 15 mixed into the high-pressure reactor 14 for hydrogenation reaction, the liquid 18 discharged from the balance drum or throttling bushing 4 arranged in front of the sealed cavity is led to a pressure of

[0039] A safety relief va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com