Integrated sucking and conveying machine

An all-in-one machine and feeding mechanism technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of large equipment occupation, low work efficiency, and limited functions, and achieve compact structure design, improve production efficiency, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

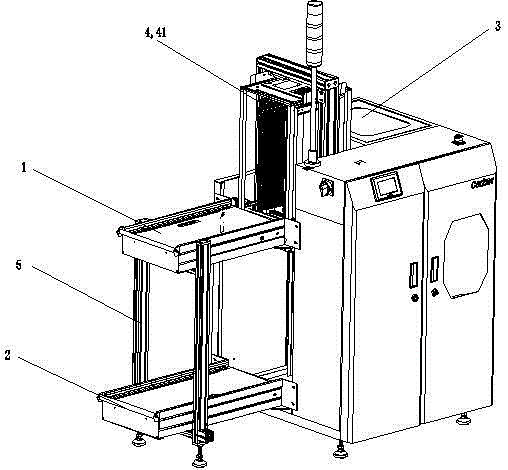

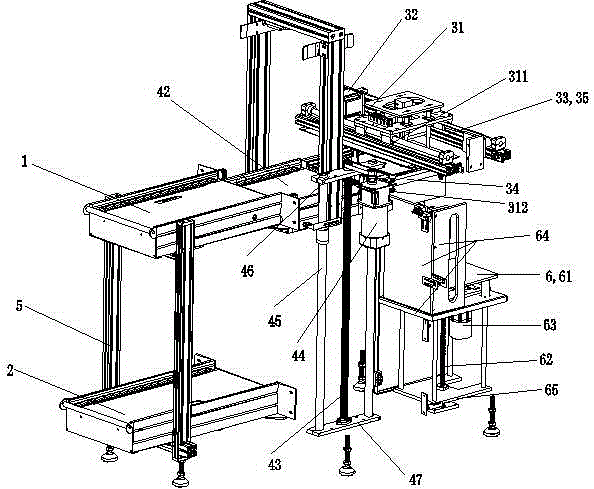

[0025] Such as figure 1 and 2 As shown, a suction and delivery integrated machine includes in turn:

[0026] -feeding mechanism, the feeding mechanism includes a feeding mechanism and a material frame lifting mechanism, the feeding mechanism includes an upper dragon tail layer 1 and a lower dragon tail layer 2 arranged up and down, the upper dragon tail layer 1 is provided with a pushing device, and the material frame lifting mechanism includes The plate feeding lifting platform 42 and the first lifting device 4 connected by the feeding mechanism, the material frame lifting mechanism also has a material frame lifting track 41; preferably, the dragon tail upper layer 1 and the dragon tail lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com