Air cylinder conveying type punching machine automatic feeding machine

An automatic feeding and conveying technology, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of laborious and time-consuming manual feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

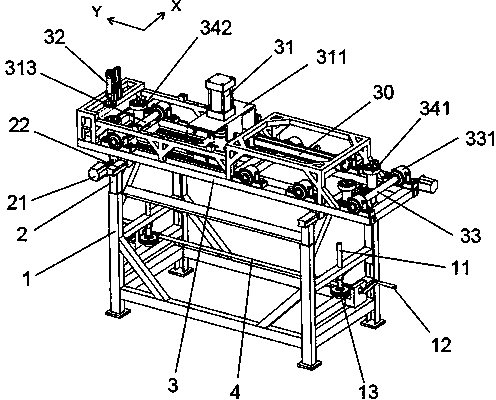

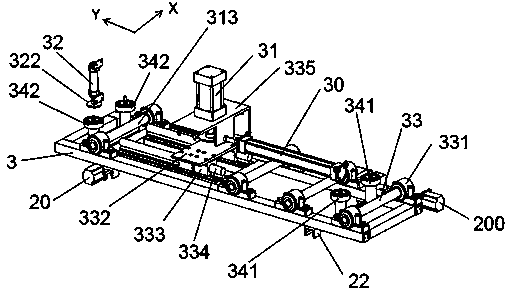

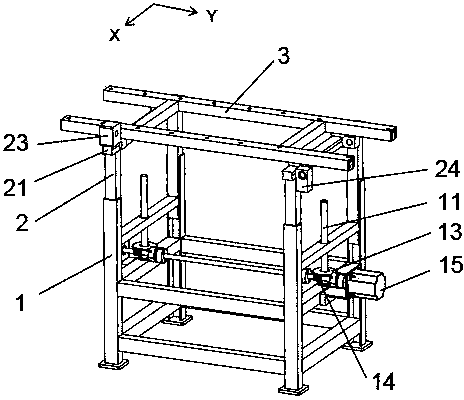

[0020] With reference to the accompanying drawings, the cylinder conveying type punch automatic feeding machine includes a base and a feeding platform 3, the feeding platform is installed on the upper base 2, and the feeding guide rail 33 is installed on the feeding end of the feeding platform through the bearing seat 331, on the feeding platform The first guide wheel group 341, the feeding module, the second guide wheel group 342 and the second pressing module are installed sequentially in the feeding direction; the first guide wheel group includes two Guide wheel, the guide wheel 41 at the top of the guide wheel is installed on the guide wheel column 47 through bearings; the described feeding module includes pushing the cylinder 30 and the first pressing device, the pushing cylinder is installed on the feeding platform, and the output shaft of the pushing cylinder It is fixedly connected with the first pressing device, and the first pressing device includes a feeding slider 3...

Embodiment 2

[0029] The difference between this embodiment and the first embodiment is that in this embodiment, the X-direction and Y-direction screw rods are connected to the handle, and the movement of the feeding platform relative to the base in the X and Y directions can be manually adjusted by rotating the handle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com