Hole-opening-device delivering device

A conveying device and hole opener technology, which is applied to conveyor control devices, conveyors, vibrating conveyors, etc., can solve the problems of inconvenient conveying hole openers and low production efficiency, and achieve simple structure, improve production efficiency, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

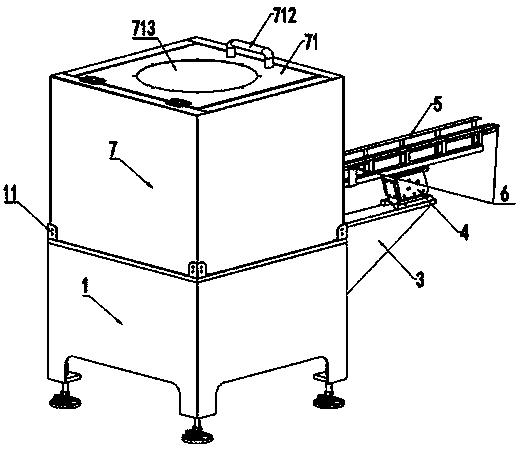

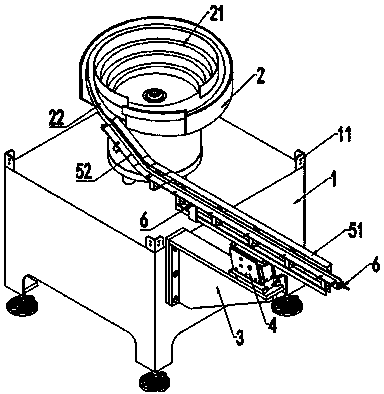

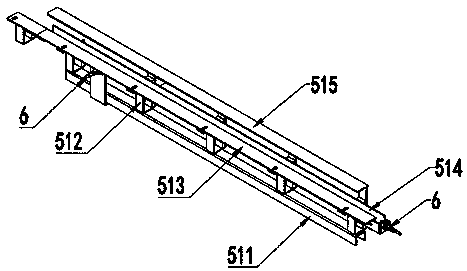

[0013] Depend on figure 1 , figure 2 , image 3 Known, a hole opener conveying device comprises a base 1, and the top of the base 1 is provided with a vibrating feeding tray 2, and the vibrating feeding tray 2 includes a spiral vibrating feeding belt 21, and a belt matching with the vibrating feeding 21. The discharge track 22 is provided with a discharge port on the discharge track 22; a mounting seat 3 is also provided on the right side of the base 1, and a linear vibrator 4 is provided on the mounting seat 3, and the top of the linear vibrator 4 is connected There is a conveying track 5; the left end of the conveying track 5 is connected to the outlet of the discharge track 22; the conveying track 5 is composed of a straight track 51 and a curved track 52, and the two ends of the straight track 51 are respectively provided with induction devices 6 ; The linear track 51 is composed of a fixed seat 511, a plurality of U-shaped connecting plates 512, a left side adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com