Rolling wheel conveying type punching machine automatic feeding machine

An automatic feeding and conveying technology, which is applied to metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of laborious and time-consuming manual feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

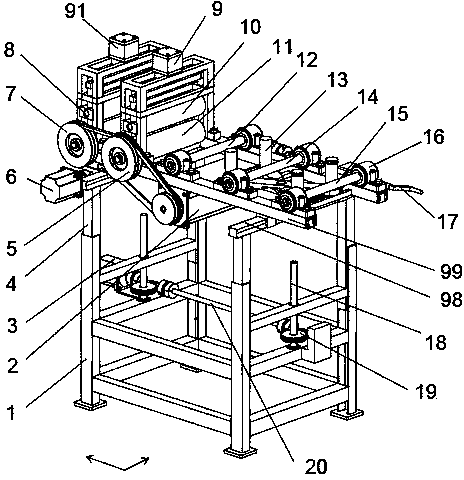

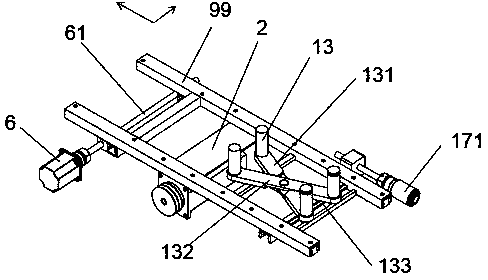

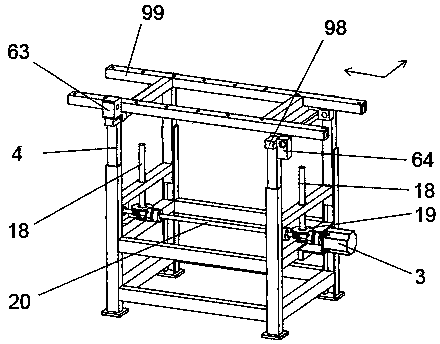

[0024] Referring to the accompanying drawings, the roller conveying type punch automatic feeding machine includes a transmission wheel 5 connected to the drive motor 2 through a conveyor belt, the transmission wheel is coaxially fixedly connected with the lower rolling pressure wheel 11, and the lower rolling pressure wheel is installed on the conveying table of the frame 99 above; the upper rolling pinch wheel 10 is installed above the lower scrolling pinch wheel, the two ends of the upper scrolling pinch wheel are fixedly connected with the slide block 8, the slide block is installed in the vertical chute, the chute is installed on the frame, and the slide block passes through The connecting rod is connected with the cylinder 9; several feeding rollers 12, 14, 15 are installed vertically along the feeding direction of the sheet metal on the conveying platform of the frame, and the two ends of the feeding rollers are installed on the frame through bearing blocks 16 ; At the fe...

Embodiment 2

[0036] The difference between this embodiment and the first embodiment is that the present invention uses a handle instead of the X-direction and Y-direction motors, and manually rotates the screw to adjust the distance of the conveying table.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com