Conveying belt type automatic feeding device

A technology of automatic feeding and conveyor belt, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problem that the time rhythm of conveying workpieces cannot be controlled, the conveyor belt cannot meet the transportation requirements, and the placement position and direction cannot be controlled. Wide, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

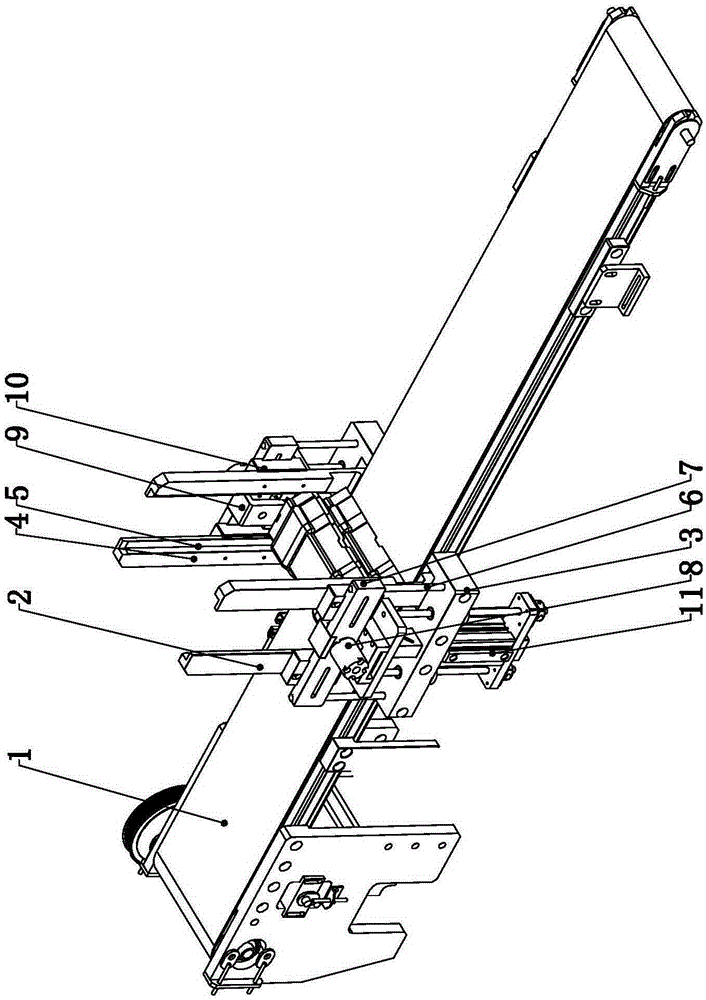

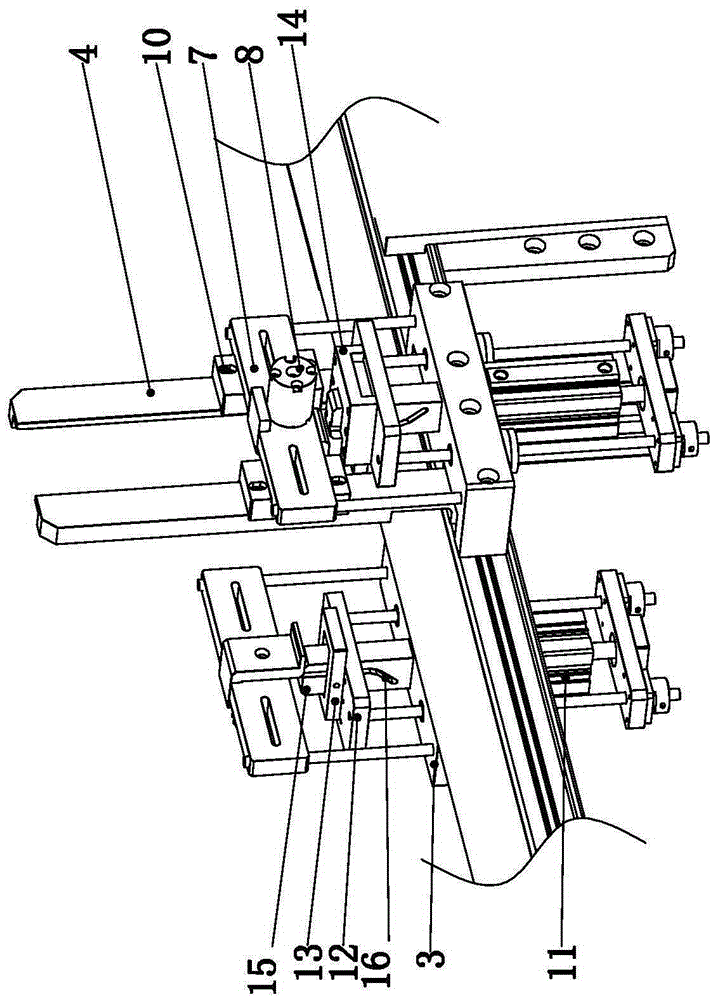

[0014] Such as Figure 1~2 As shown, the present invention mainly comprises conveyor belt 1 and the automatic feeding device 2 that is connected on both sides of conveyor belt 1 by bolts, and automatic feeding device 2 comprises discharging mechanism, locking mechanism, feeding mechanism and fixed plate 3, and fixed plate 3 From top to bottom, there are discharging mechanism, locking mechanism and feeding mechanism in sequence.

[0015] The discharge mechanism includes four discharge limit rods 4 fixed on the transmission belt 1. The four discharge limit rods 4 are symmetrically distributed in pairs on both sides of the conveyor belt 1. The inner side of each discharge limit rod 4 is provided with a discharge Feed trough 5. Four discharge limit rods 4 constitute the vertical channel for workpiece loading, and the workpiece can be accurately loaded th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com