Waste steam heating, pressurizing and recycling system

A stripping and high-pressure technology, applied in steam recovery, steam engine installations, engine components, etc., can solve the problems of few applicable occasions, environmental thermal pollution, low exhaust steam pressure, etc., to reduce power consumption, improve operating efficiency, improve The effect of flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to explain the present invention more clearly and to better understand the present invention, the present invention will be further described through specific embodiments in conjunction with the accompanying drawings.

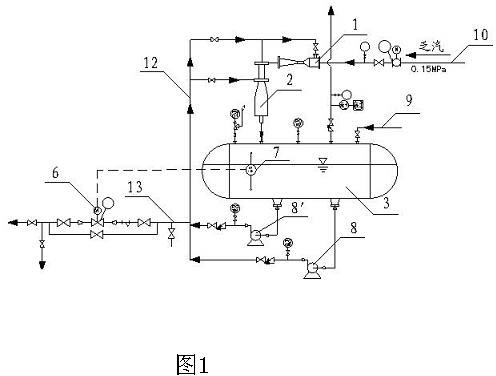

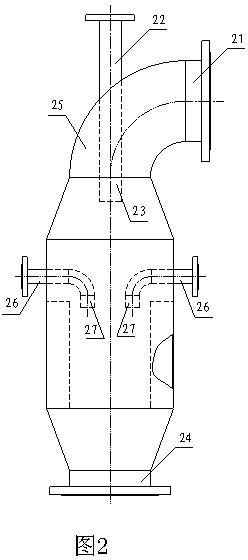

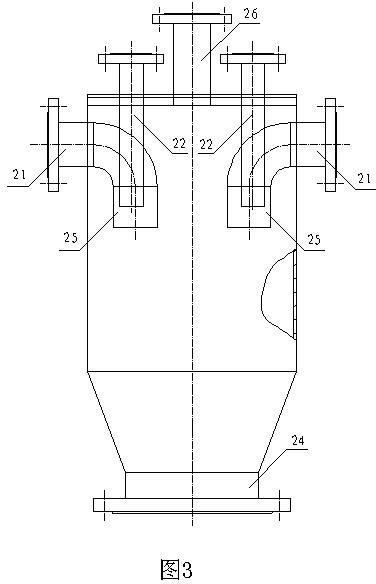

[0027] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention provides a waste steam stripping temperature lifting pressure recycling system, including a primary jet pump 1, a secondary jet pump 2 and a recovery tank 3 for pressurized delivery of low-pressure exhaust steam, through the primary and secondary The fluid delivered by the jet pump to the recovery tank realizes vapor-liquid separation in the return tank. The lower part is liquid water, and the upper part is steam and gas. , liquid two-phase contact surface, improve the separation efficiency, and the larger cross-sectional area is also conducive to ensuring the input and output of the recovery tank at the same time, avoiding mutual interference and short circuit o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com