Silicon chip feeding and calibrating device for photoetching machine and silicon chip feeding and calibrating method

A technology for calibrating devices and lithography machines, which is applied in the direction of photolithography exposure devices, photomechanical equipment, micro-lithography exposure equipment, etc., which can solve the problems of low efficiency of silicon wafer transportation, long waiting time, and failure of silicon wafers. Calibration and positioning and other issues, to achieve the effect of realizing calibration, achieving roundness, and smooth connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below through specific examples.

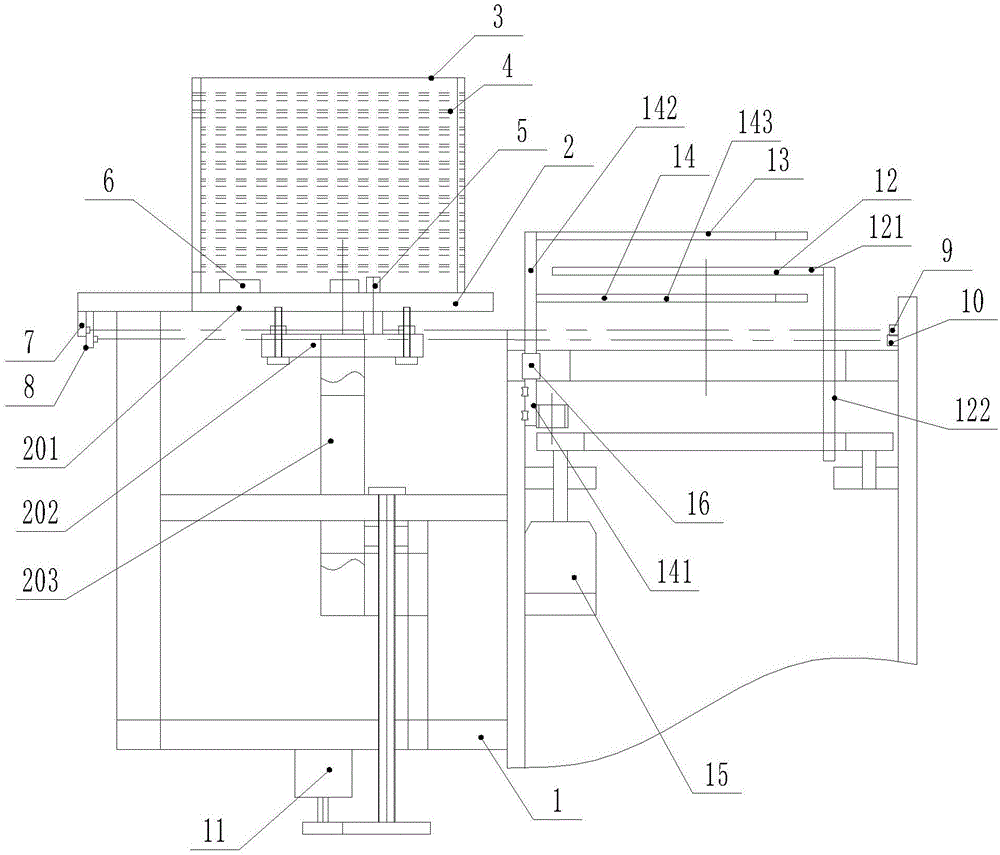

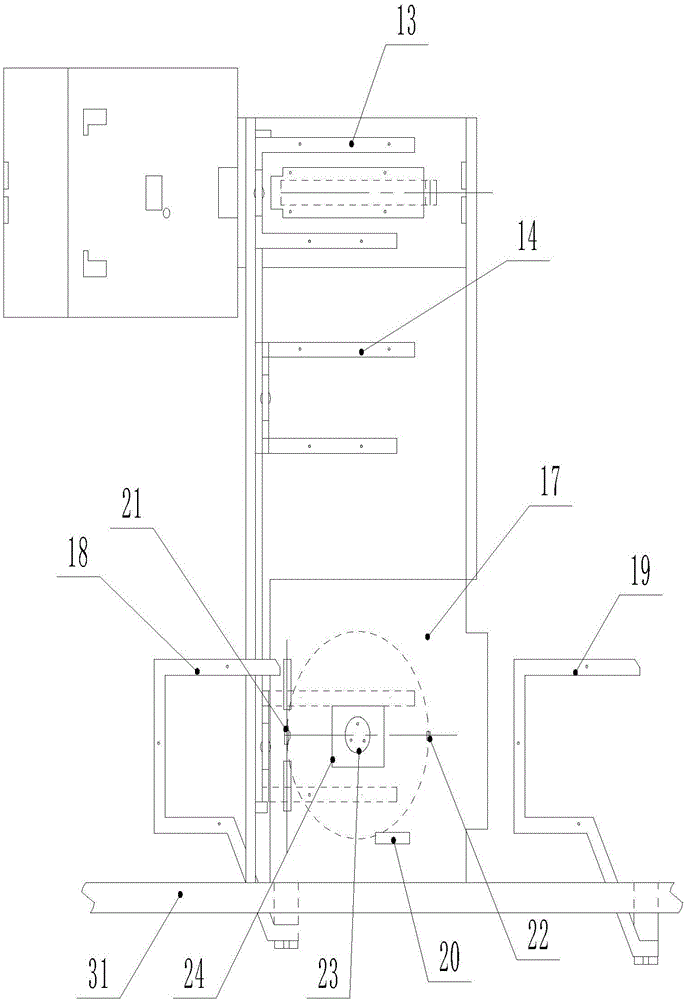

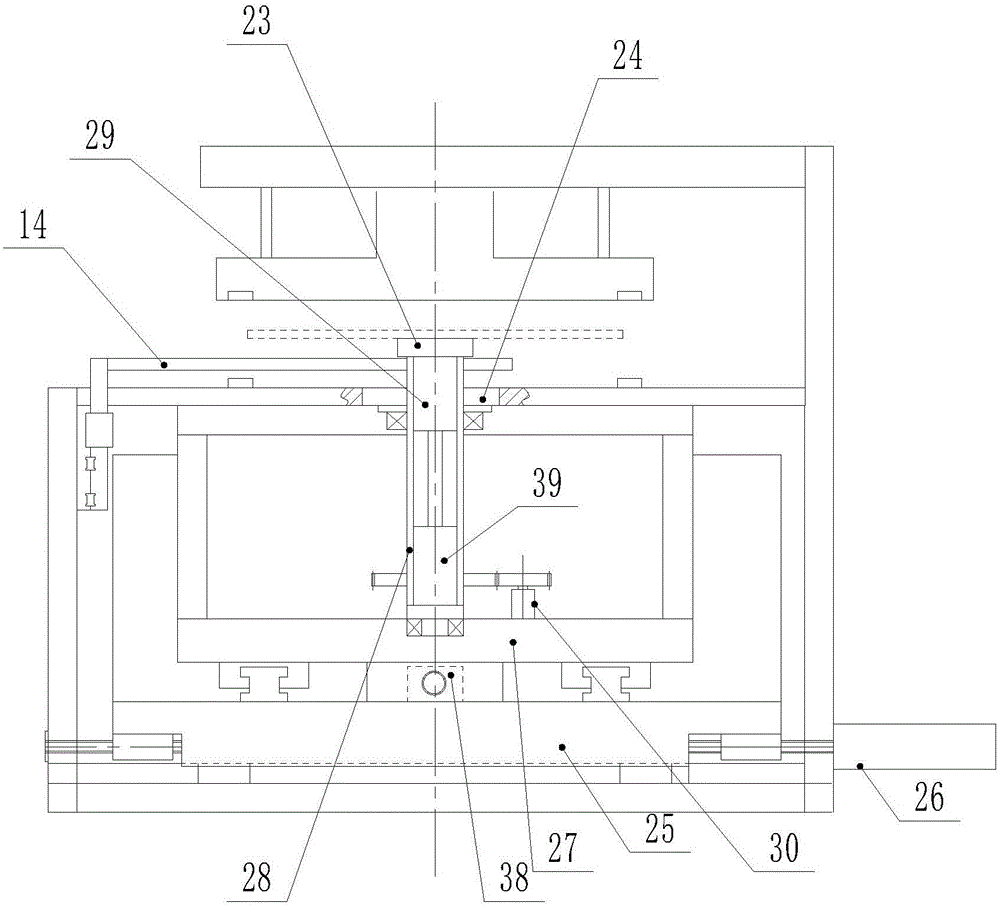

[0043] Such as Figure 1 to Figure 5 As shown, a silicon wafer feeding calibration device for a lithography machine includes a frame on which a lifting seat for placing a cassette is vertically slidably installed, and the lifting seat is driven and connected by a first lifting power device , the lifting seat includes a placement platform, a connecting base and a vertical seat, the placing platform is fixed on the upper end of the connecting base, the connecting base is fixed on the upper end of the vertical seat, and the vertical seat is vertically slidably installed on the machine through guide rails. On the shelf, the vertical seat is connected to the first lifting power device in transmission, and the positioning boss corresponding to the bottom of the film box is arranged on the said placing platform, and a contact switch is also arranged on the placing platform, and only th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com