Automatic cargo loading all-in-one machine

An all-in-one, automatic technology, used in conveyors, loading/unloading, mechanical conveyors, etc., can solve the problems of many equipment, no goods, narrow application scope, etc., to reduce the cost of use, save loading time, and simple structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

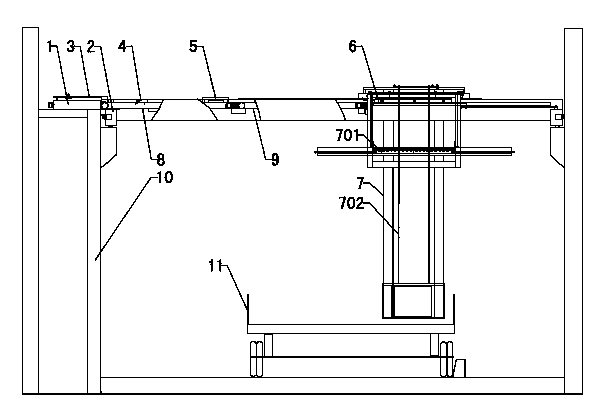

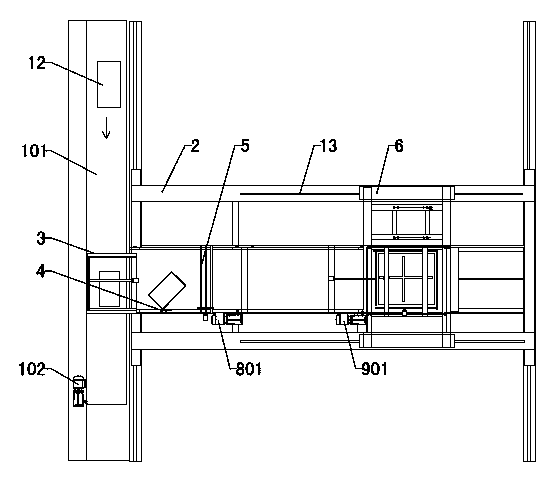

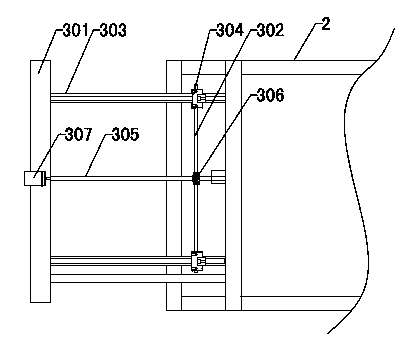

[0025] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0026] Refer to attached figure 1 and 2 : The integrated machine for automatic loading of goods includes a longitudinal belt conveying mechanism 1, a transverse conveying mechanism, a positioning mechanism and a loading and stacking mechanism 7, and the longitudinal belt conveying mechanism 1 includes a longitudinal belt 101 and a longitudinal conveying that drives the longitudinal belt 101 to realize forward and backward movement The motor 102 is provided with a transverse conveying mechanism perpendicular to it on one side of the longitudinal belt conveying mechanism 1, and the transverse conveying mechanism comprises a transverse support 2 and a transverse conveying belt fixed on the transverse support 2, and an adjustment is arranged sequentially above the transverse conveying belt. Mechanism 4 and stack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com