Logistics freight classification handling device

A technology of loading and unloading devices and sorting devices, which is applied in the directions of loading/unloading, transportation and packaging, etc. It can solve the problems of inability to classify goods of different sizes and weights, the goods are easy to collapse, time-consuming and labor-intensive, etc., to ensure the efficiency of automatic unloading and avoid collapse. fall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

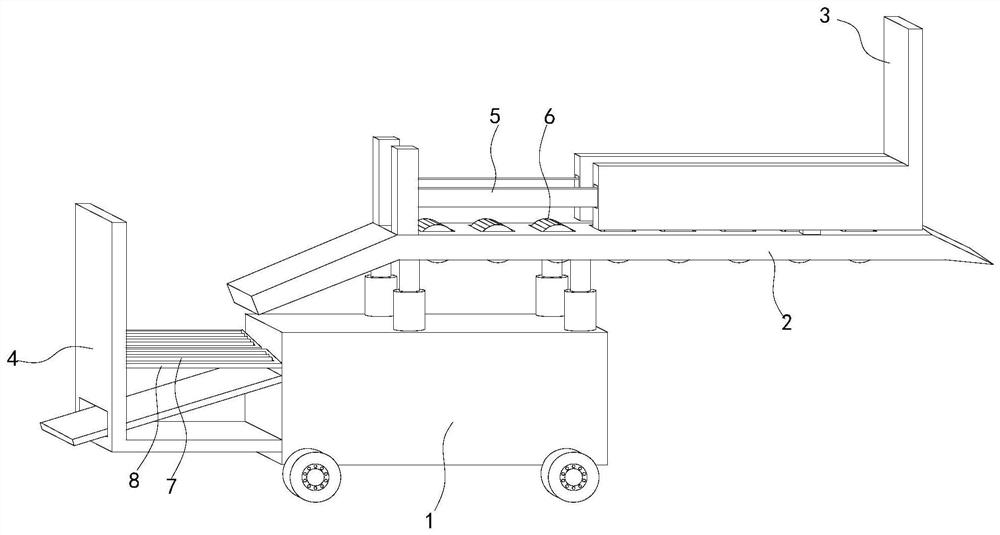

[0029] see Figures 1 to 9 , a schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a logistics goods classification loading and unloading device.

[0030] A logistics cargo classification loading and unloading device, comprising a device main body 1, an unloading plate 2 is movably installed on the upper end of the device main body 1, a cargo blocking device 3 is movably installed on the upper end of the unloading plate 2, and a sorting device 4 is fixedly installed on the left side of the device main body 1.

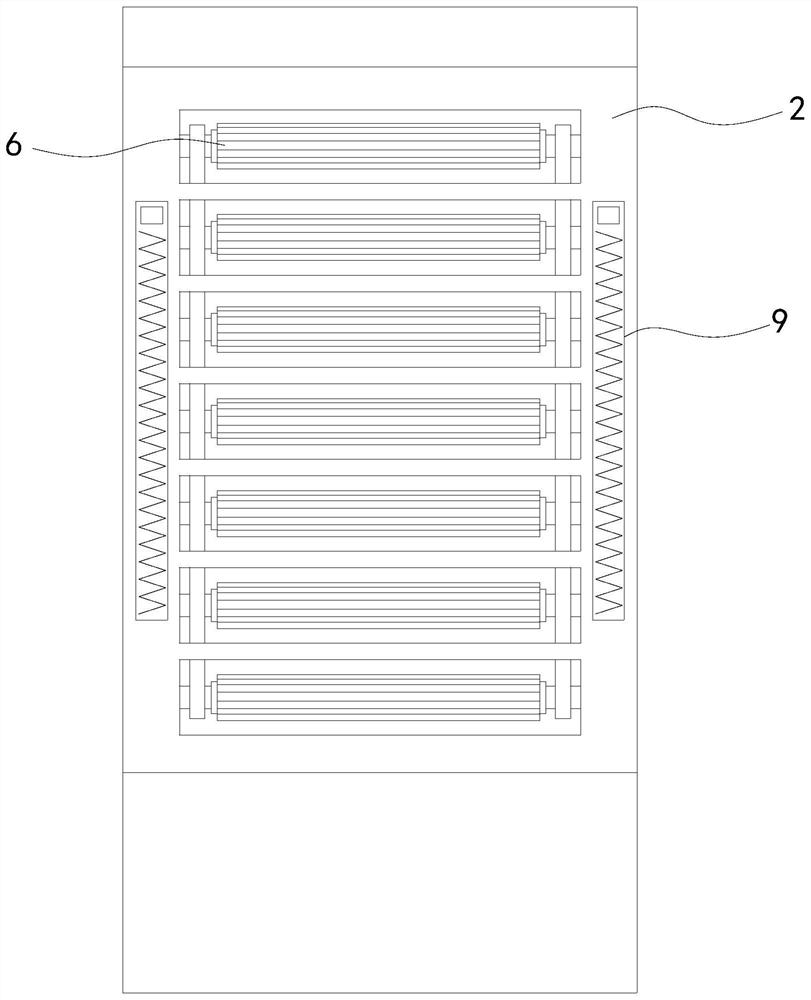

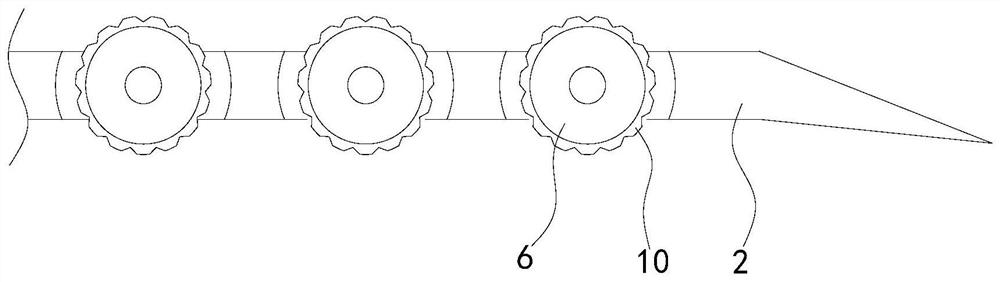

[0031] In the specific implementation, the right end of the unloading plate 2 is inclined, and the cargo runner 6 is fixedly installed in the unloading plate 2, so that when the unloading plate 2 is inserted into the bottom of the carriage under the drive of the main body 1 of the device, the inside of the carriage can be moved. The goods are held up, and then the device main body 1 moves backward to take the goods out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com