Gas sensor

A gas sensor and sensor element technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of sensor element damage, large thermal shock, sensor element application, etc., and achieve the effect of increasing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

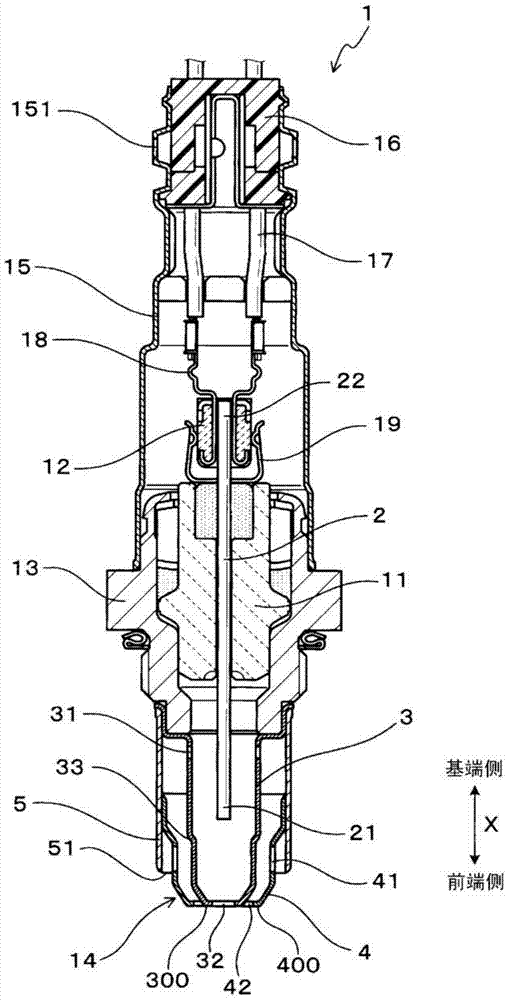

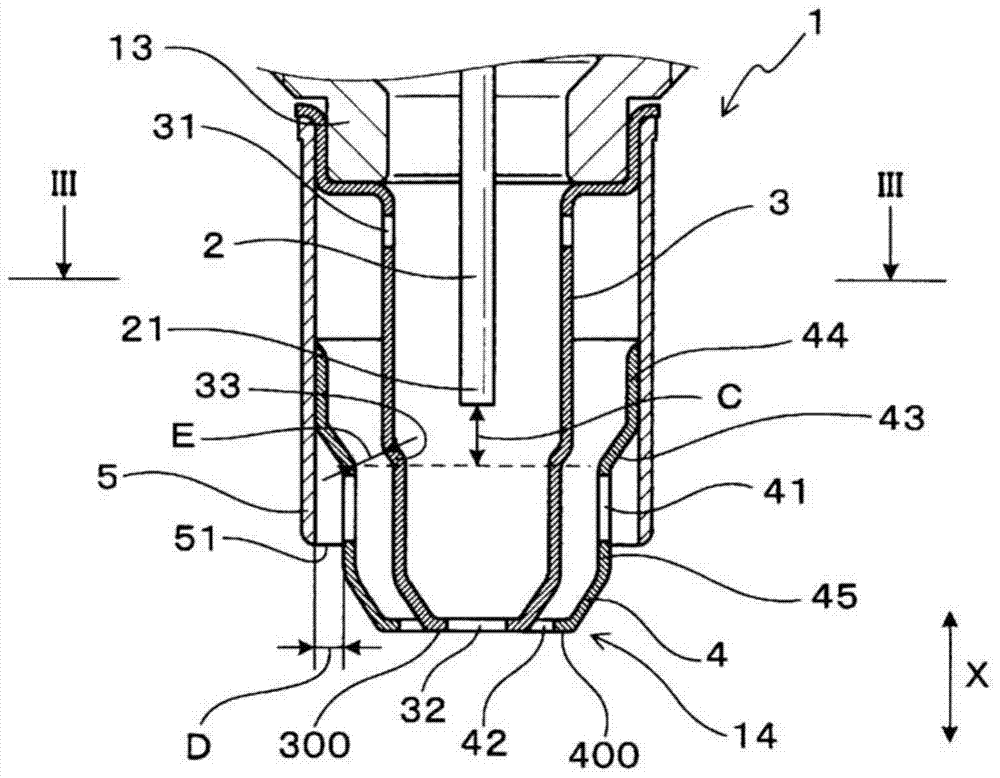

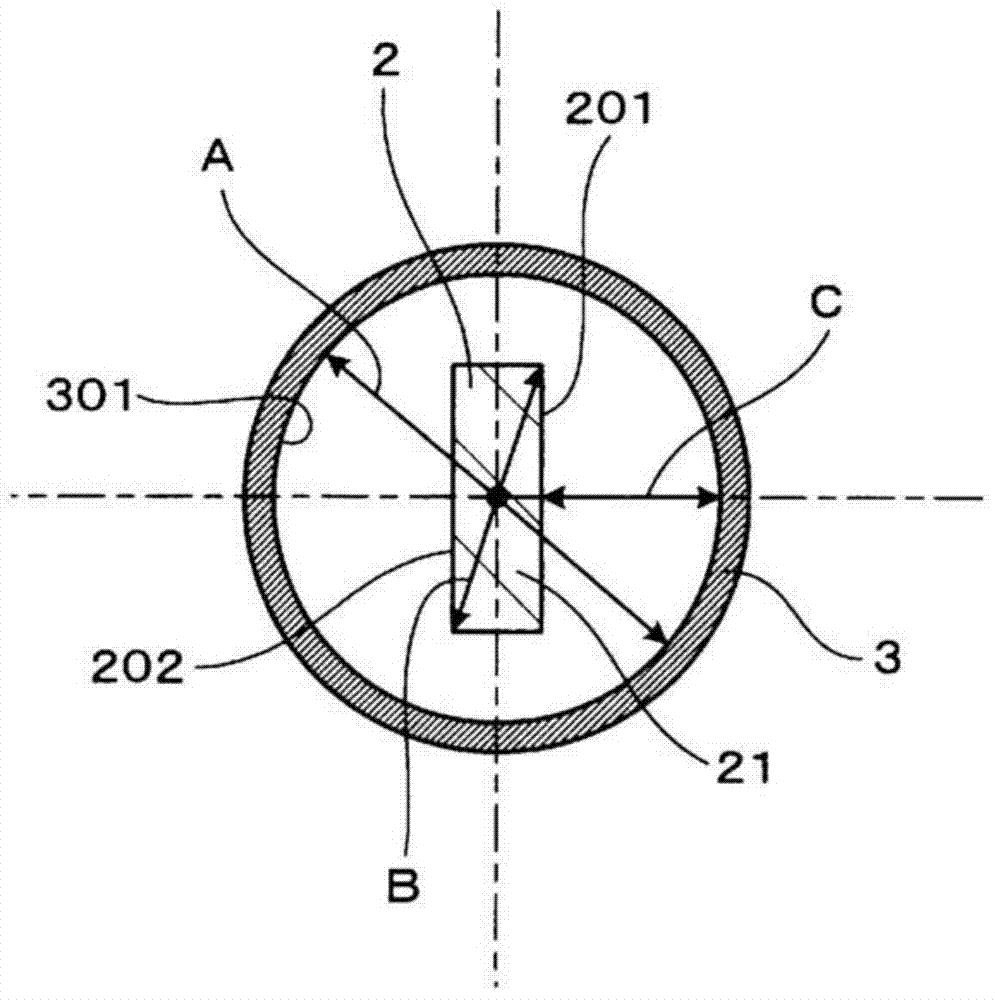

[0072] The gas sensor 1 in this example is as Figure 1 ~ Figure 3 It includes a sensor element 2 for detecting the concentration of a specific component in a gas to be measured (namely, a gas to be measured), a case 13 through which the sensor element 2 is inserted, and an element cover 14 disposed on the front end side of the case 13 .

[0073] The element cover 14 has an inner cover 3 arranged to cover the front end portion 21 of the sensor element 2 , and an outer cover 4 arranged outside the inner cover 3 . The outer cover 4 has an outer introduction hole 41 through which the gas to be measured is introduced, and an outer discharge hole 42 provided on the front end side than the outer introduction hole 41 . The inner cap 3 has an inner introduction hole 31 provided on the proximal side than the outer introduction hole 41 to introduce the gas to be measured, and an inner discharge hole 32 provided on the distal side than the inner introduction hole 31 .

[0074] As shown ...

Embodiment 2

[0113] Such as Image 6 As shown, this example is an example in which the structures of the outer cover 4 and the protective cover 5 are changed.

[0114] In this example, if the Image 6 As shown, the outer cover 4 is formed so as to extend toward the base end side than the protective cover 5 , and is fixed to the front end side of the housing 13 together with the inner cover 3 . In addition, the protective cover 5 is fixed to the fixing portion 46 on the side wall of the outer cover 4 that is closer to the proximal side than the outer diameter-reduced portion 43 .

[0115] Other basic structures and effects are the same as in Example 1.

Embodiment 3

[0117] Such as Figure 7 As shown, this example is an example in which the structure of the protective cover 5 is changed.

[0118] In this example, if the Figure 7 As shown, a protruding portion 52 protruding radially inward is provided at the front end portion of the protective cover 5 . Furthermore, the protective cover 5 has a front end side opening 51 that opens toward the front end side between the protruding portion 52 and the outer cover 4 .

[0119] Other basic structures and effects are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com